Farmer-Helper 25 & 27G

12

Revision06/2017

LUBRICATION

The Model 27G is designed to require little maintenance and lubrication. However, it is still

important to keep all moving parts well lubricated. Following a regular maintenance and lubri-

cation schedule will enhance the operation and increase the life of the spreader significantly.

The following pages show the grease points on the spreader. The operator should establish a

systematic routine to ensure complete and quick lubrication of the spreader.

The spreader should be greased every 50 loads or once a month. Wipe the old grease and any

dirt or dust off the grease fittings before greasing so it doesn’t get forced into the bearing.

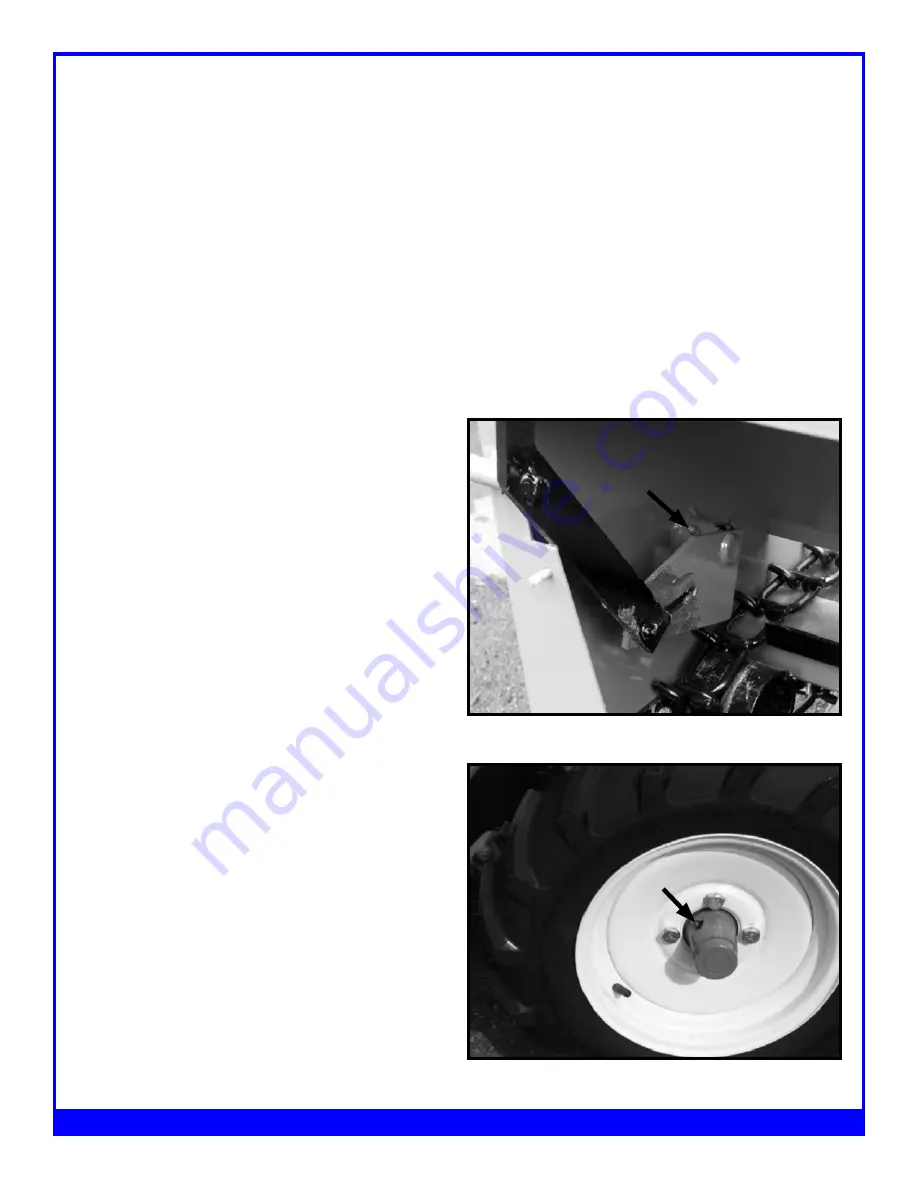

There are two grease fittings inside the

front cover on the engaging lever pivot.

One on each side of the spreader.

Figure 6

There is a grease fitting on each wheel

hub.

Figure 7

Summary of Contents for FH-25G

Page 6: ...Farmer Helper 25 27G 6 Revision06 2017...

Page 18: ...Exploded View of 25G Manure Spreader Farmer Helper 25G 18...

Page 20: ...Exploded View of Spreader Box Farmer Helper 25G 20...

Page 23: ...Exploded View of Transmission Assy Farmer Helper 25G 23...

Page 26: ...Exploded View of Tire Assy Farmer Helper 25G 26...

Page 28: ...Exploded View of Widespread Shaft Assy Farmer Helper 25G 28...

Page 30: ...Exploded View of Chain Tension Assy Farmer Helper 25G 30...

Page 32: ...Exploded View of Hitch Assy Farmer Helper 25G 32...