Summary of Contents for FH-25G

Page 6: ...Farmer Helper 25 27G 6 Revision06 2017...

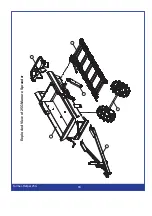

Page 18: ...Exploded View of 25G Manure Spreader Farmer Helper 25G 18...

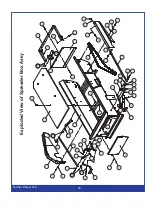

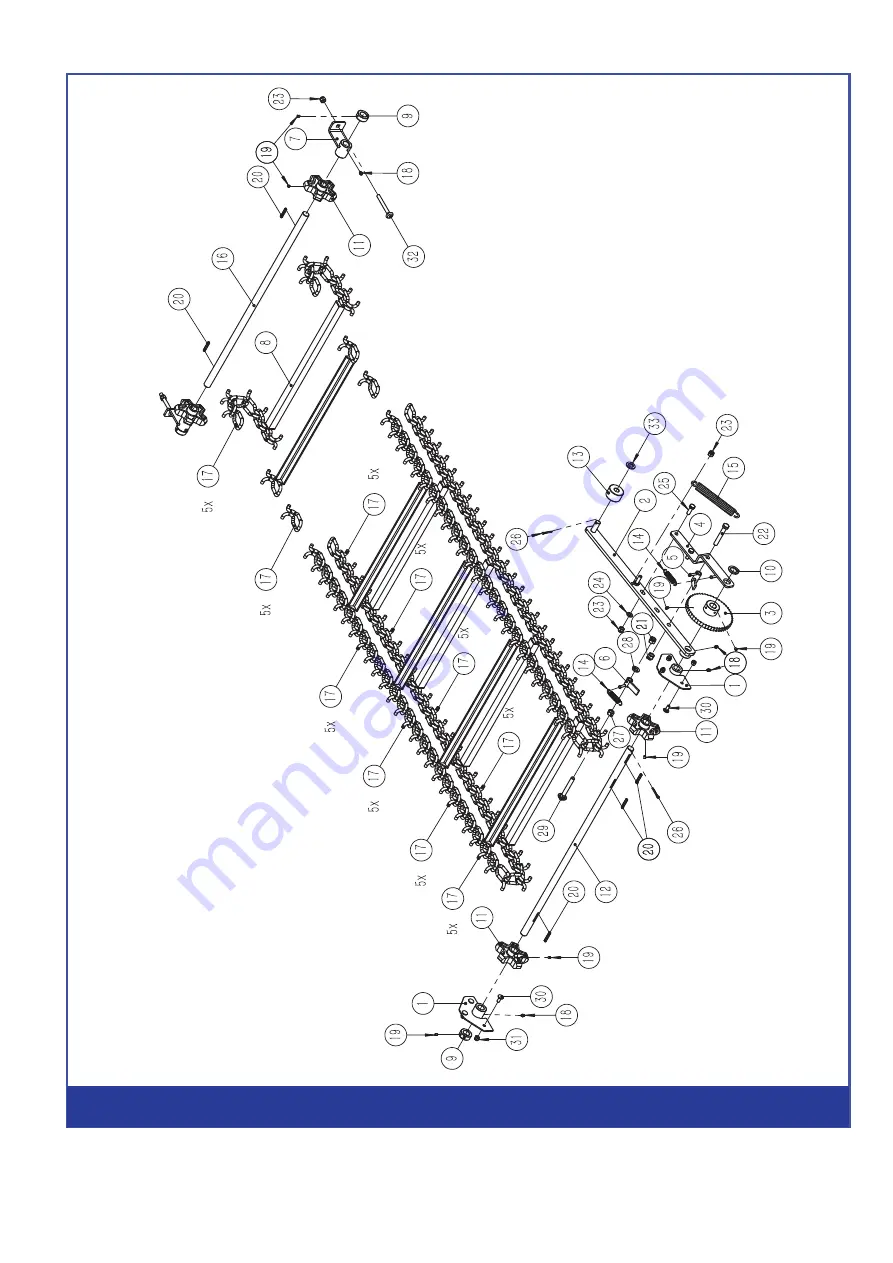

Page 20: ...Exploded View of Spreader Box Farmer Helper 25G 20...

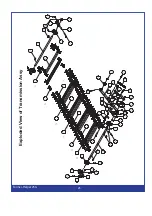

Page 23: ...Exploded View of Transmission Assy Farmer Helper 25G 23...

Page 26: ...Exploded View of Tire Assy Farmer Helper 25G 26...

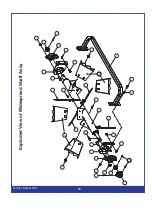

Page 28: ...Exploded View of Widespread Shaft Assy Farmer Helper 25G 28...

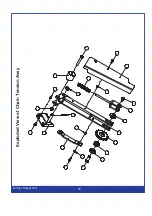

Page 30: ...Exploded View of Chain Tension Assy Farmer Helper 25G 30...

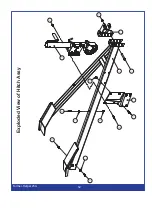

Page 32: ...Exploded View of Hitch Assy Farmer Helper 25G 32...