Hollow shaft display with serial output

EP43RS / EP46RS

Date: 06/04/21

File: EP4RS_4.1_ing.doc

Rev: 4.1

Page: 5/12

Target Value

//

//

//

//

Value shown on the first line of the display which indicates the position which must be reached by manual

adjustment.

Backlash compensation value

,,

,,

,,

,,

If set different to zero, at each inversion of the rotation direction, the displayed value does not change until

the shaft completes a rotation which is equal to or above the backlash compensation value.

Set a positive value for backlash compensation in the forward direction and a negative value for

compensation in the reverse direction.

Tolerance around target value

+,

+,

+,

+,

When the actual value reaches inside the window around the target value (which is defined by the tolerance)

the red LED is turned off the green LED is turned on.

Example: with target value

//

//

//

//

=50 and

+,

+,

+,

+,

=10, the green LED is on between 40,1 e 59,9.

Address device

%%.

%%.

%%.

%%.

This is the identification address of the unit, it must be unique for every device connected to the bus network,

acceptable values from 1 to 247.

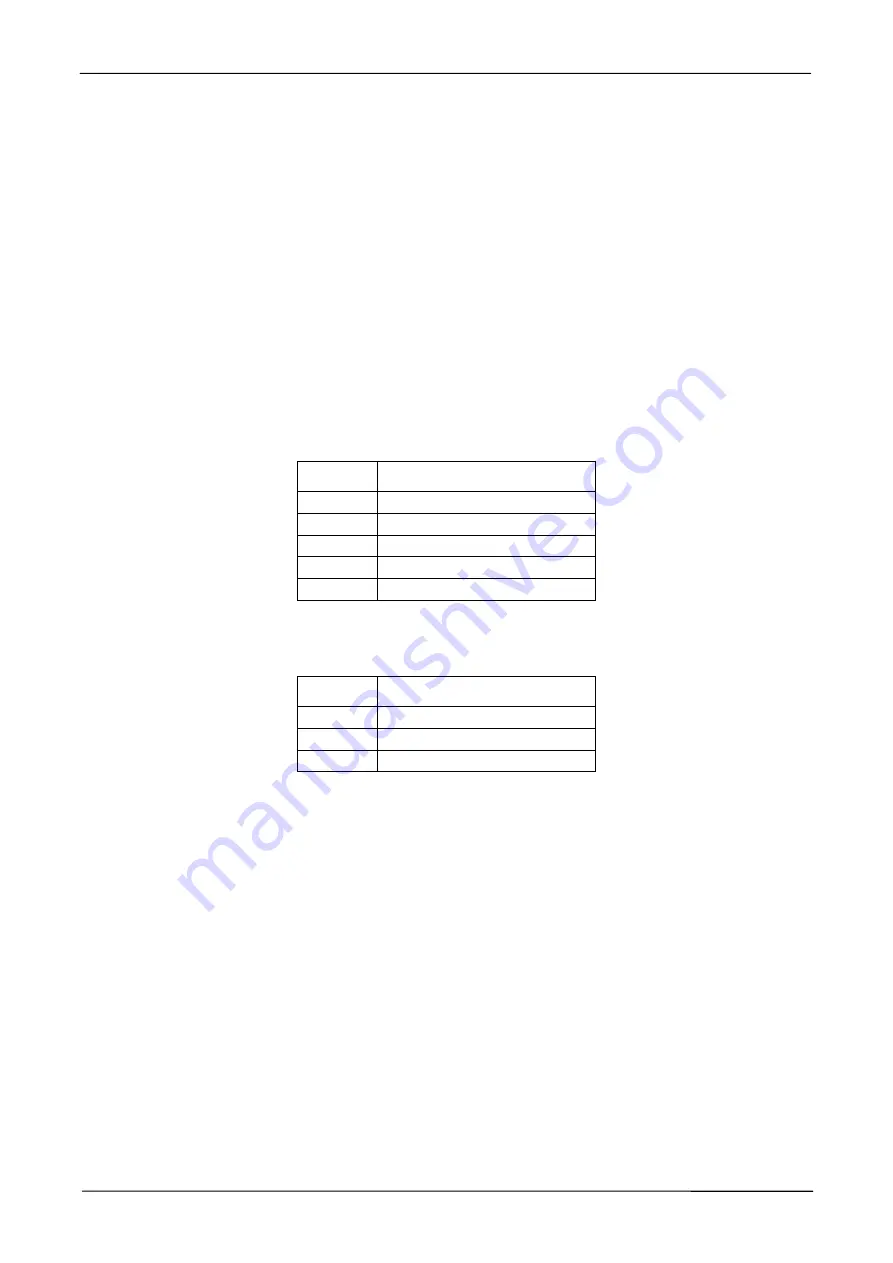

Baud rate serial port communication

# %.

# %.

# %.

# %.

VALUE

Baud rate

0

9600

1

19200

2

38400

3

57600

4

115200

Parity bit

.

.

.

.

This constant sets the serial communication parity bit.

VALUE

Parity

0

even

1

odd

2

no parity, 2 stop bit

Adjustment of displayed value

After the installation of instrument on the machine and setting of all parameters, in order to visualize on the

display the correct value it is necessary to carry out the reset or preset.

Position the shaft in a position where the correct measurement that has to be visualized is known exactly (for

example the stroke end point) or measure the position in that position of the shaft. Program parameter

+//

+//

+//

+//

with value 3 in the first digit on the right and exit programming.

Now press

O

and

./

./

./

./

will appear, press again 2 times

O

and set the correct value to display, then confirm

with

O

The display will now show the desired value.

If the required value is zero, instead of the preset function it is possible to use the reset function by setting 1

in the first digit on the right in the

//

//

//

//

parameter so that pressing

O

will bring the displayed value to zero.

Now that the instrument is adjusted, it is necessary to insert the desired

//

//

//

//

parameter to avoid

accidental reset/preset of the displayed value.