MAT2_

Data: 15/01/18

file: MAT2_ing.doc

Rev:2

pag 5/7

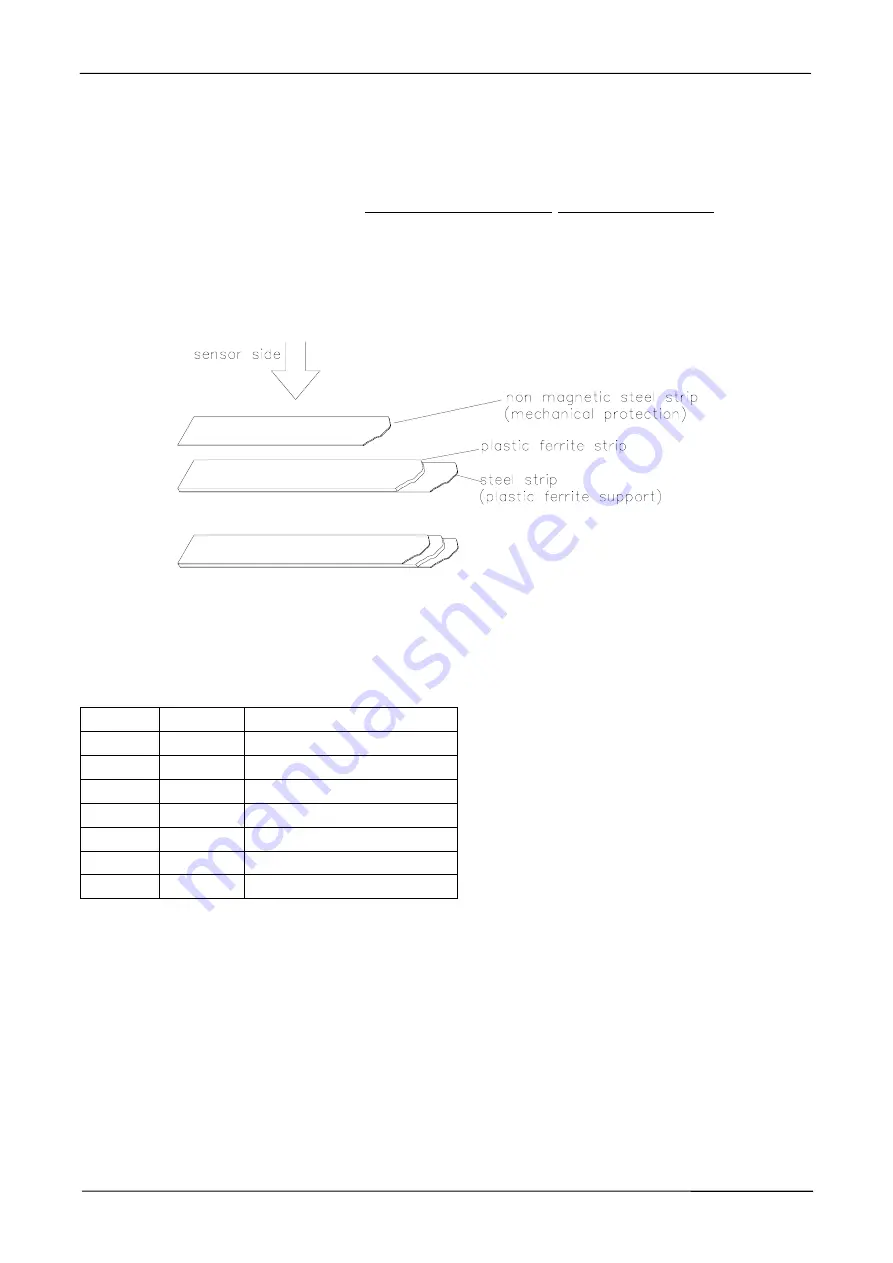

Magnetic band

The band consists of a magnetized plastic ferrite strip with alternate magnetic poles, carried by a

ferromagnetic steel strip. Mechanical protection of the plastic ferrite strip is supplied by a non magnetic steel

strip with tickness 0,2mm.

The magnetic band is assembled by sticking it with a biadhesive tape. The surface has to be smooth, clean

and dry: is advisable to clean it with a degreasing product (isopropyl alcohol, ethyl alcohol, solvents, etc). The

magnetic band has to be sticked holding the plastic ferrite side in the direction of the sensor, which means

the steel side leaned on the stand surface. Fixed the magnetic band, to keep off damages due to abrasions

or grazes of the plasic ferrite strip, is advisable the appliance (always biadhesive) of the non magnetic

protection streep.

The optimal ambient temperature for stick the biadhesive tape is over 10°C. The maximum adherence of the

tape works out after 48 hours (about) of the application and is kept between –10 and 80°C.

Electrical wiring

Brown

+24Vdc

Positive power supply

Green

GND

Negative power supply

Yellow

CK+

Clock+ SSI

Orange

CK-

Clock – SSI

White

D+

Data+ SSI

Purple

D-

Data - SSI

Grey

ZR

Zero input (PNP)

Black

DIR

Direction input (PNP)