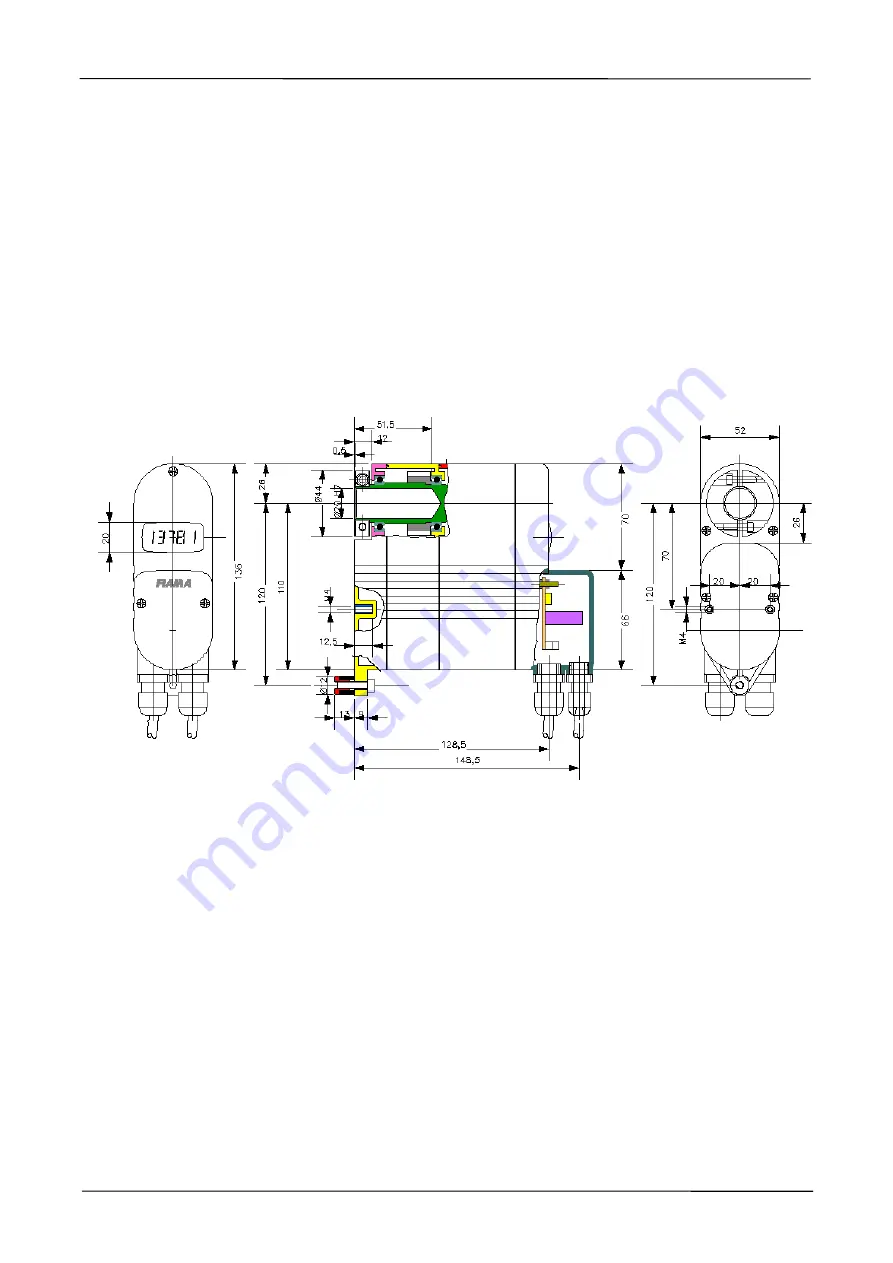

Positioning unit

SERVO.M_E-P

Data: 01/12/20

file: Servo.M_EP_CS_1.7_ing.doc

pg 3/7

Description

The positioning unit SERVO.M is made of a geared motor in direct current with microprocessor control of the

driving gear and of an incremental position transducer (encoder) or absolute (precision potentiometer)

assembled on the output shaft with interface for field bus and display with 5 digits. It realises in a single and

compact device a complete system for the control of axis being able to receive by bus a dimension to reach

and start with the positioning by a control type PID. The version

SERVO.M-E

has a position transducer with

an incremental optic encoder, while the version

SERVO.M.P

has a precision potentiometer.

The SERVO.M unit has a hollow shaft output to enable a simple assembling and a versatile use, even with

pre-existent manual motion machines that have to be automated. Therefore it is suitable for a large number

of applications in machinery within industries such as printing, packaging, woodworking,

marble, plastic, etc. A simple linking and lay out are guaranteed by a supervisor (PC, PLC), the system

interfaces with a bus-field to control the positioning and enable the modifications of the control parameters

(present quota, speed, state).

The communication record can be MODBUS RTU, CANopen, PROFIBUS DP.

For the electric connection there are separate ways for the power-supply and communications cables: the

SERVO.2M has 2 press-cables PG9 for the input and output of the connections, the SERVO.3M has 3 press-

cables for the input and output (2 PG9, 1 PG7).

Installation

Before installing the instrument, read the following warnings:

a) Connect the instrument strictly following the instructions of the manual.

b) Carry out the connections using the correct wires within the limits of the tension and power supply as

indicated in the technical data.

c) The instrument does not have an ON/OFF switch, hence it comes on when connected to the power supply.

For safety reasons, the equipment connected permanently to the power supply requires a bi-phase selector

switch which should be within easy reach of the operator.

d) If the instrument is connected to any apparatus not isolated electrically, carry out an earth connection to

avoid it being connected directly through the structure of the machine.

e) It is the responsibility of the user to check, before using , the correct settings of the parameters of the

instrument to avoid damage to persons or things.

f) The instrument cannot function in a dangerous environment (inflammable or explosive). It can be

connected to elements that operate in the same atmosphere only through appropriate interfaces, according

to the current safety

regulations.

g) Avoid dust, humidity, corrosive gases, heat sources.