2/13

21689_r03

INSTRUCTION FOR USE

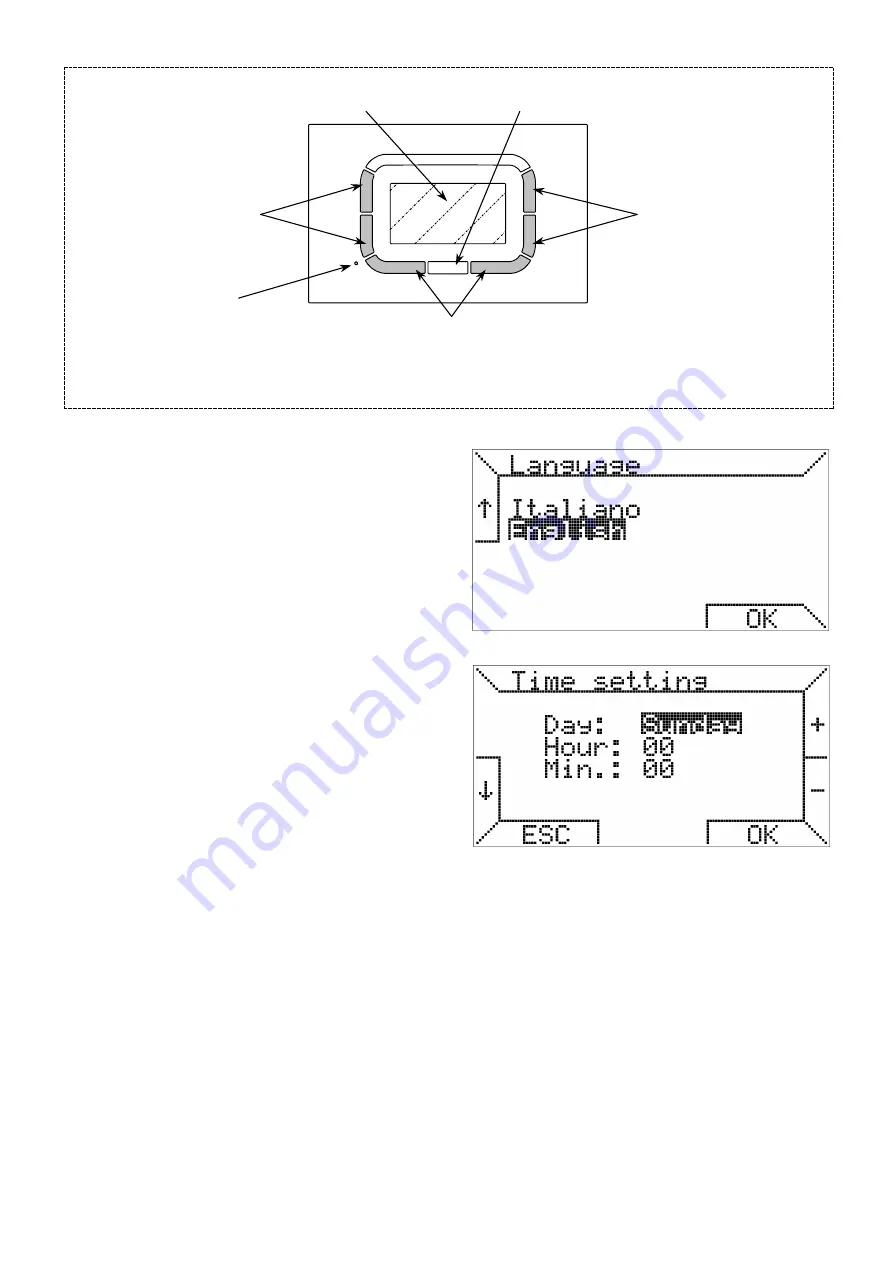

The FIAMMA OT11 provides the user with a graphic LCD

dot-matrix, a series of buttons in silicon rubber, and an LED

indicator located below a button plastic transparent to

display the parameters and interact with the heating

system. Figure 1.

The buttons have any versatile utilization depending on the

selected menu.

The use of buttons is facilitated by the indications with text,

icons and other graphics that appear on the display.

The vertical buttons on the left of the display are typically

used to navigate the setup menu or to select the

parameters.

The vertical buttons on the right of the display are used to

vary temperature and the classical function increase /

decrease (+ / -).

To facilitate the change of set values, the long press of

these buttons accelerates the increase or decrease.

The horizontal buttons at the bottom serve to confirm or

cancel the settings, or to enter and exit the submenus.

The center button to used for special functions as the

unlock of the boiler.

Under the center button there is an LED:

•

LED with color red continuous: error or no

communication with the boiler;

•

LED with color red intermittent: boiler lockout;

•

LED with color yellow intermittent: anomaly;

•

LED

with

color

green

continuous:

the

chronothermostat is resuming work after a power

failure.

The most frequently used functions by the user are

available in the main menu.

It is possible to quickly browse through the pages to set, for

example, environment temperature or the domestic hot

water temperature.

The first time or after a reset of the OT11, appears the

language menu, as shown in the figure below.

Pushing buttton OK, you confirm the selection.

This choice can be changed later, if necessary, through the

"SETTING MENU".

Then the current time can be entered.

Also in this case the buttons to the left allow you to select

the various menu items, while the right buttons are used to

change the values, the OK button stores the settings while

the ESC button allows you to continue without changing the

data time.

If you press ESC, the subsequent reconnection of the

cronothermostat (for example power down) you will again

be prompted to select the language and set the current

time.

Figure 1:

description of the remote control unit

graphic display (LCD)

hole for

access to the

reset button

function buttons

(the active command is indicated on the graphic display)

multifunction button with LED

buttons to

increase and

decrease

temperatures and

parameters

buttons to select

or change the

function

parameters