T5-2-10

EX355

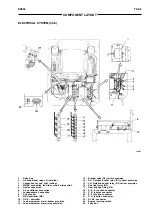

COMPONENT LAYOUT

1

- Pump Control Valve

(In 5-Spool Section)

2

- Check Valve

3

- Main Relief Valve

4

- Check Valve

5

- Flow Combiner Valve

6

- Check Valve

7

- Load Check Valve (Bucket)

8

- Bucket Flow Control Valve

(Poppet Valve)

9

- Bucket Flow Rate Control Valve

(Switch Valve B)

10 - Overload Relief Valve

(Bucket)

11 - Load Check Valve

(Boom 1 Parallel Passage)

12 - Boom Regenerative Valve

13 - Boom Anti-Drift Valve

(Check Valve)

14 - Overload Relief Valve (Boom)

28 - Load Check Valve (Swing)

29 - Arm Anti-Drift Valve:

Rod Side (Switch Valve)

30 - Arm Anti-Drift Valve:

Bottom Side (Switch Valve)

31 - Arm Anti-Drift Valve:

Bottom Side (Check Valve)

32 - Arm Anti-Drift Valve:

Bottom Side (Relief Valve)

33 - Overload Relief Valve (Arm)

34 - Arm Anti-Drift Valve:

Rod Side (Check Valve)

35 - Load Check Valve

(Boom 2 Parallel Passage)

36 - Load Check Valve

(Aux. Parallel Passage)

37 - Travel Flow Rate Control Valve

38 - Load Check Valve

(Travel Tandem Passage)

15 - Arm Regenerative Valve

16 - Check Valve

17 - Bucket Flow Rate Control Valve

(Switch Valve A)

18 - Bypass Shut-Out Valve

19 - Pump Control Valve

(In 4-Spool Section)

20 - Load Check Valve

(Arm 2 Tandem Passage)

21 - Needle Valve

22 - Boom Anti-Drift Valve

(Switch Valve)

23 - Orifice

24 - Load Check Valve

(Arm 2 Parallel Passage)

25 - Load Check Valve

(Arm 1 Parallel Passage)

26 - Orifice

27 - Load Check Valve

(Arm 1 Tandem Passage)

SM6041

Travel Motor (Right)

Bucket

Cylinder

Boom

Cylinder

Arm

Cylinder

Swing Motor

Pump 1

Pump 2

Travel Motor (Left)

Summary of Contents for EX355 Tier2

Page 22: ...T1 2 10 EX355 COMPONENT LAYOUT NOTES ...

Page 37: ...T2 1 14 EX355 CONTROL SYSTEM NOTES ...

Page 47: ...T2 2 10 EX355 HYDRAULIC SYSTEM NOTES ...

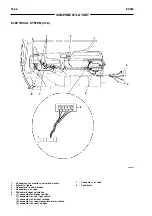

Page 73: ...T2 3 26 EX355 ELECTRICAL SYSTEM NOTES ...

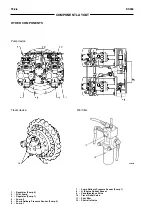

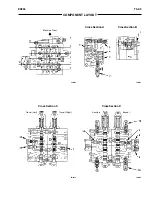

Page 86: ...T3 1 12 EX355 PUMP DEVICE NOTES ...

Page 94: ...T3 2 8 EX355 SWING DEVICE NOTES ...

Page 134: ...T3 4 10 EX355 PILOT VALVE NOTES ...

Page 146: ...T3 5 12 EX355 TRAVEL DEVICE NOTES ...

Page 156: ...T3 7 4 EX355 OTHER COMPONENTS Undercarriage NOTES ...

Page 195: ...T4 2 6 EX355 STANDARD NOTES ...

Page 199: ...T4 3 4 EX355 ENGINE TEST NOTES ...

Page 215: ...T4 4 16 EX355 EXCAVATOR TEST NOTES ...

Page 237: ...T4 5 22 EX355 COMPONENT TEST NOTES ...

Page 265: ...T5 2 12 EX355 COMPONENT LAYOUT NOTES ...

Page 325: ...T5 4 52 EX355 TROUBLESHOOTING B ...

Page 372: ...EX355 T5 6 9 ELECTRICAL SYSTEM INSPECTION ...

Page 385: ...T5 6 22 EX355 ELECTRICAL SYSTEM INSPECTION NOTE ...

Page 425: ...W1 1 4 EX355 PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY NOTES ...

Page 450: ...W2 3 8 EX355 MAIN FRAME NOTES ...

Page 454: ...W2 4 4 EX355 PUMP DEVICE SM5510 ...

Page 456: ...W2 4 6 EX355 PUMP DEVICE SM5510 ...

Page 458: ...W2 4 8 EX355 PUMP DEVICE ASSEMBLE PUMP DEVICE SM6205 SM6206 ...

Page 460: ...W2 4 10 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 462: ...W2 4 12 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 464: ...W2 4 14 EX355 PUMP DEVICE SM6205 SM6206 ...

Page 468: ...W2 4 18 EX355 PUMP DEVICE SM6210 ...

Page 470: ...W2 4 20 EX355 PUMP DEVICE SM6210 ...

Page 472: ...W2 4 22 EX355 PUMP DEVICE SM6210 ...

Page 474: ...W2 4 24 EX355 PUMP DEVICE SM5511 SM6219 ASSEMBLE MAIN PUMP ...

Page 476: ...W2 4 26 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 478: ...W2 4 28 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 480: ...W2 4 30 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 482: ...W2 4 32 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 484: ...W2 4 34 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 486: ...W2 4 36 EX355 PUMP DEVICE SM5511 SM6219 ...

Page 498: ...W2 4 48 EX355 PUMP DEVICE NOTES ...

Page 532: ...W2 5 34 EX355 CONTROL VALVE NOTES ...

Page 540: ...W2 6 8 EX355 SWING DEVICE SM6277 31 18 17 20 19 21 3 24 27 25 26 10 ...

Page 542: ...W2 6 10 EX355 SWING DEVICE SM6277 31 19 2 1 23 22 ...

Page 566: ...W2 7 12 EX355 PILOT VALVE 11 19 17 18 1 2 3 8 13 14 16 15 SM1114 ...

Page 572: ...W2 7 18 EX355 PILOT VALVE 8 6 7 1 3 4 5 9 21 2 SM1119 ...

Page 586: ...W2 7 32 EX355 PILOT VALVE NOTES ...

Page 592: ...W2 8 6 EX355 PILOT SHUT OFF VALVE NOTES ...

Page 602: ...W2 10 6 EX355 SOLENOID VALVE UNIT NOTES ...

Page 621: ...W3 2 10 EX355 TRAVEL DEVICE SM5108 44 8 13 12 1 45 46 28 27 25 26 24 36 38 30 31 32 ...

Page 627: ...W3 2 16 EX355 TRAVEL DEVICE SM5502 3 4 5 20 7 8 9 10 12 14 13 16 11 6 ...

Page 643: ...W3 2 32 EX355 TRAVEL DEVICE NOTES ...

Page 651: ...W3 3 8 EX355 CENTER JOINT NOTES ...

Page 655: ...W3 4 4 EX355 TRACK ADJUSTER 8 14 13 11 17 12 SM6284 ...

Page 657: ...W3 4 6 EX355 TRACK ADJUSTER 3 4 8 10 16 15 14 SM6284 ...

Page 659: ...W3 4 8 EX355 TRACK ADJUSTER 3 6 4 8 10 9 SM6284 18 ...

Page 667: ...W3 4 16 EX355 TRACK ADJUSTER NOTES ...

Page 671: ...W3 5 4 EX355 FRONT IDLER 1 SM6290 2 4 3 5 6 8 12 7 6 3 4 1 2 9 10 11 ...

Page 689: ...W3 6 14 EX355 UPPER AND LOWER ROLLER NOTES ...

Page 708: ...W4 1 10 EX355 FRONT ATTACHMENT NOTES ...

Page 716: ...W4 1 18 EX355 FRONT ATTACHMENT NOTES ...

Page 744: ...W4 2 28 EX355 CYLINDERS NOTES ...

Page 763: ...EX355 W5 1 17 GENERAL INFORMATION Oil Pan N m kgf m Ib ft SM7010 ...

Page 765: ...EX355 W5 1 19 GENERAL INFORMATION Water Pump N m kgf m Ib ft SM7012 ...

Page 815: ...EX355 W5 3 35 ENGINE OVERHAUL Disassembly SM7093 1 Camshaft gear 2 Knock pin 3 Camshaft ...

Page 883: ...EX355 W5 3 103 ENGINE OVERHAUL Reassembly 1 Crankshaft 3 Crankshaft gear 2 Pin SM7239 ...

Page 894: ...W5 3 114 EX355 ENGINE OVERHAUL NOTE ...

Page 938: ...W5 7 6 EX355 ENGINE INDUCTION NOTE ...