- 27 -

Note

: A vertical line sometimes appears at the splice point when MM fibers, or dissimilar fibers (different diam-

eters) are spliced. This does not affect splice quality, such as splice loss or tensile strength.

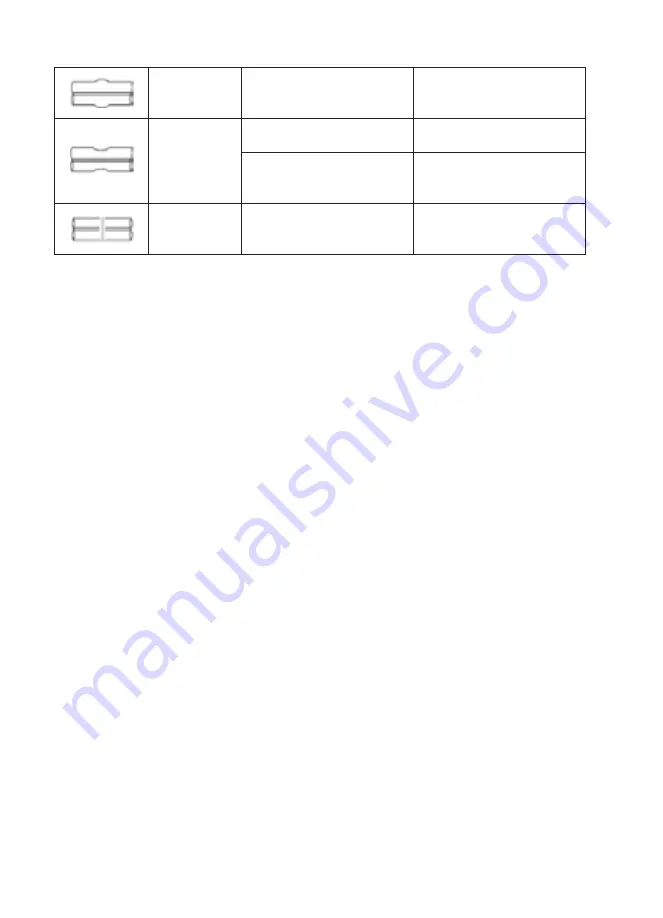

Fat

Fiber stuffing too much

Decrease [Overlap] and

perform [Motor clibration]

Thin

Arc power not adequate

Perform [Arc calibration]

Some arc parameters not

adequate

Adjust [Prefuse power],

[Pre-fuse time] or [Overlap]

Line

Some arc parameters not

adequate

Adjust [Prefuse power],

[Pre-fuse time] or [Overlap]

Summary of Contents for Mini5C

Page 25: ... 25 ...

Page 33: ... 33 ...