6

The most recent installation instructions can be found on our website.

Please visit https://www.fiberondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

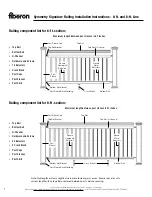

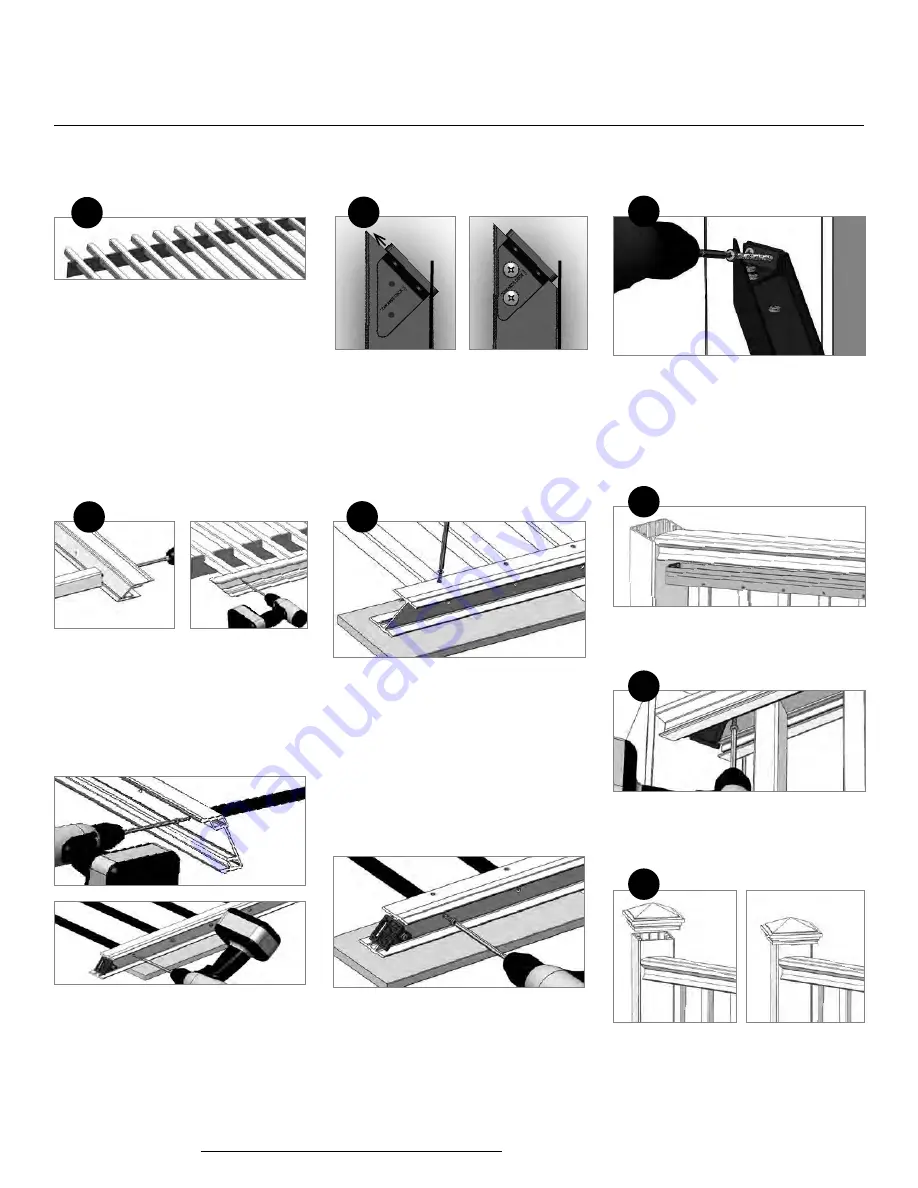

Square Composite Balusters:

Measure and

trim all balusters to the required length.

Remove the baluster guide from the railing

box. Place on a flat surface and insert the

balusters into the precut slots.

Note: Square composite baluster lengths

will very slightly due to manufacturing

processes. Insure balusters are cut to

uniform length.

Note: Round metal balusters do not require

trimming.

6

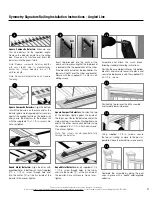

Square Composite Balusters:

Align the bottom

rail with the balusters on the same end as the

baluster guide. Hold square balusters securely

against the aligning feature on the bottom rail

and secure the balusters to the bottom rail

with the supplied #10 x 1-1/2-in. screws. Do

not over-tighten

Round Metal Balusters:

Align baluster with

predrilled holes in bottom rail. Insert supplied

#10 x 1-1/2-in. screw through hole and

into the center (“X”) of the fins inside of the

baluster. Do not over-tighten.

7

9

Square Composite Balusters:

Position the top

of the balusters tightly against the inside of

the top H-bar. Center the balusters under the

side-mounting screw holes. Working from one

end to the other, secure each baluster using

the supplied #8 x 1-1/2-in. flat head screws.

Do not over-tighten.

Note: The screws should penetrate fully

through the baluster.

8

Insert top brackets into the cavity of the

aluminum H-bar, ensuring that the top bracket

is located within the boundaries of the H-bar.

If the bracket is outside of the boundaries, the

top rail will not fit over the H-bar and bracket.

Secure with the supplied #10 x 5/8-in. self-

drilling screws.

NO

YES

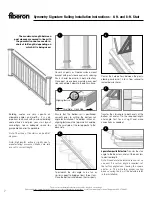

Assemble and attach the crush block

following standard line railing instructions.

Position the assembled infill over the bottom

brackets and carefully lower into place and

secure the top brackets with the supplied #10

x 2-1/2-in. screws.

10

Position the top rail over the infill assembly,

and carefully lower into place.

11

Using supplied 1-1/2-in. screws, secure

the top rail starting as close to the post as

possible. Space the remaining screws evenly.

Complete the assembly by gluing the post

caps in place with a quality exterior-grade

adhesive.

12

Symmetry Signature Railing Installation Instructions - Angled Line

Round Metal Balusters:

Insert supplied #10 x

1-1/2-in. screw through holes in the H-bar,

and into the center (“X”) of the fins inside of

the baluster. Drive until secure. Do not over-

tighten.

13