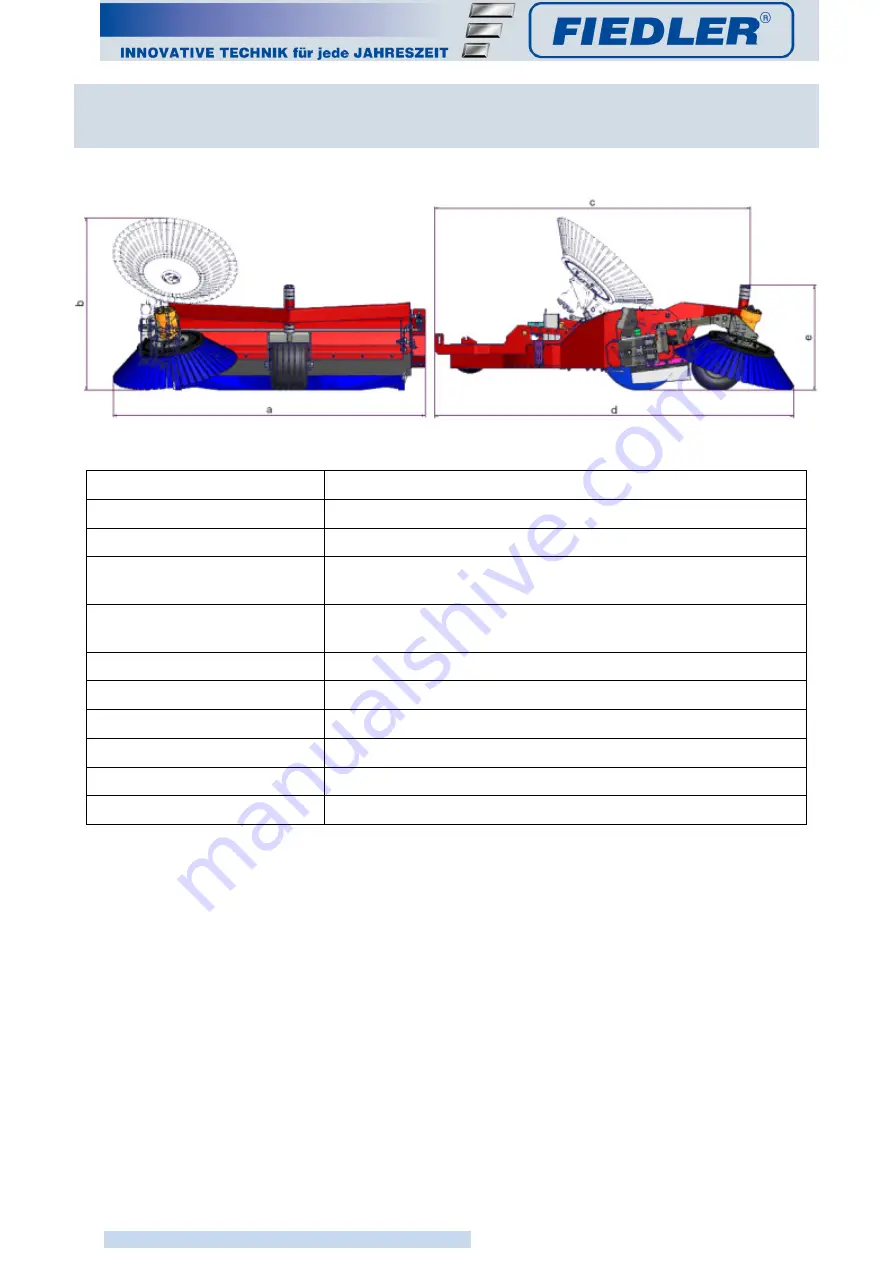

FLA 1250 H

Technical data

14

INNOVATIVE TECHNOLOGY FOR ALL SEASONS

3 Technical data

a

(machine width)

1,610mm

b

(machine height, transport)

880mm

c

(machine length, transport)

1,650mm

d

(machine length, when

working)

1,850mm

e

(machine height, when

working)

550mm

Work area

1.25m (1.50m with side brush)

Work width

1.25m (1.50m with side brush)

required oil quantity

40–45l/min at 180bar

Weight

200kg

Controls

electro-hydraulically operated vehicle hydraulics

Hydraulic supply

throughout the carrier vehicle

Tab.

1

Technical data