Page 3

TABLE 1

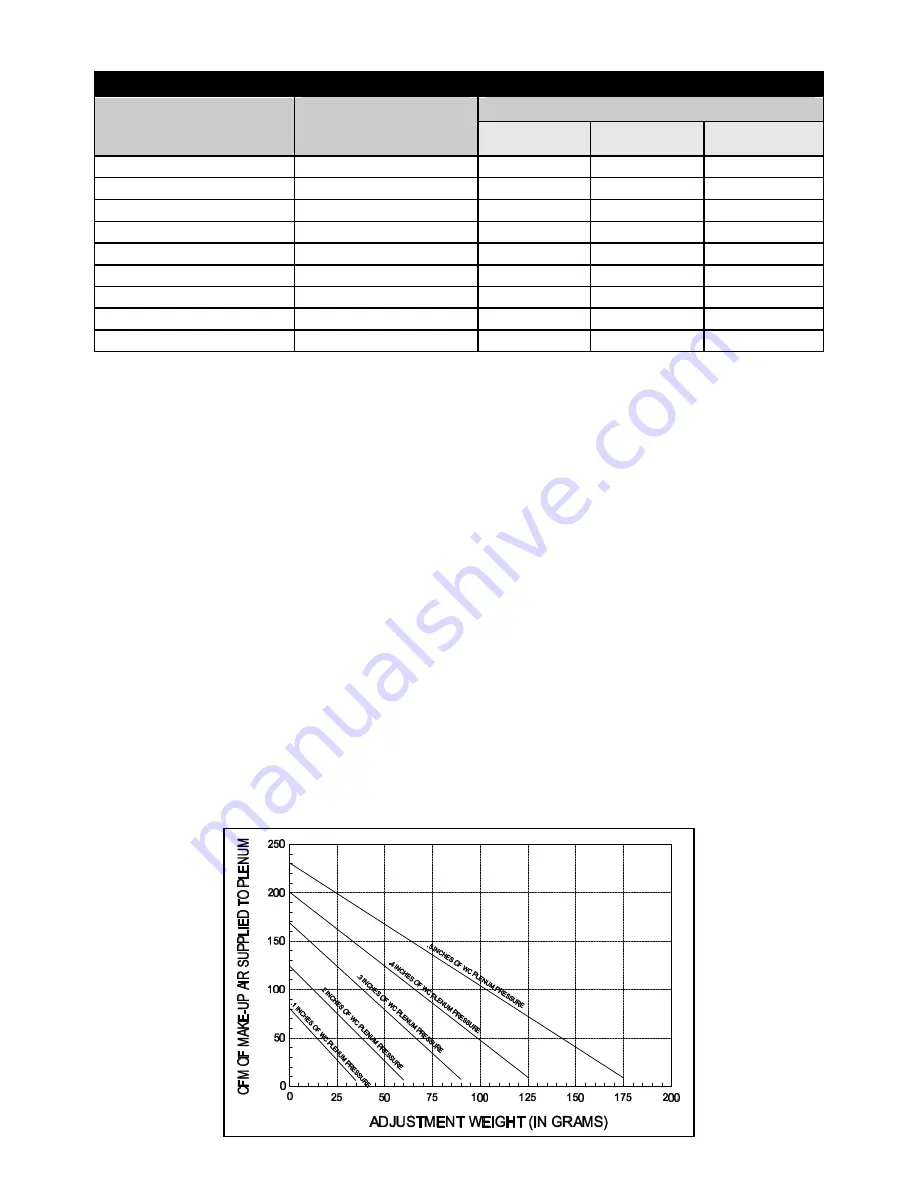

AIRFLOW CHART

NUMBER OF ADJUSTMENT WEIGHTS ADDED

BUILDING SQUARE FEET

APPROXIMATE CFM

OF MAKE-UP

SUPPLIED TO PLENUM

SMALL

LARGE

GRAMS

1000

67

19

1

88

1250

83

13

1

76

1500

100

8

1

66

1750

117

2

1

54

2000

133

20

-

40

2250

150

16

-

32

2500

167

11

-

22

2750

183

3

-

6

3000

200

-

-

-

The cfm of make-up air was based on 1/2 air changes per hour in the building, an average ceiling height of 8

feet and a return air plenum pressure of .4 inches of water column.

C

ALUCULATE

CFM O

F

M

AKE

U

P

A

IR

To adjust the metering air damper for different air changes per hour, building volumes or different return air pressures

refer to Table 1.

1. Calculate building volume: Building square feet x average ceiling height.

2. Estimate desired building air change per hour (ACPH).

Typical ACPH for buildings

:

Tight construction -.35 to .5

Average construction -.5 to .75

Loose construction .75 to 1.00

3. Calculate required CFM of make up air:

(Building volume x ACPH) ÷ 60.

4. Measure return air plenum pressure. In inches of water column pressure.

5. Refer to chart (or see example)

EXAMPLE:

2,000 sq. ft. building with 8 foot high ceilings required air changes per hour = .5 ACPH. Furnace return air

plenum pressure .3 inch.

1. Building volume = 2,000 sq. ft. x 8 ft. = 16,000 cu. ft.

2. Required CFM = (16,000 cu. ft. x .5) ÷ 60 = 133 CFM. Entering the chart at 133 CFM draw a line horizontally until

it intersects the .3 pressure curve. Then draw a line vertically down to the weight axis. For this example the

amount of weight to add to the weight level assembly would be 20 grams or 10 small washers.