Page 3

8. Draw a horizontal line on Diagram A or B that passes through the point located in step 5. The

position of the point along this line relative to the left and right borders of the region it falls into

indicates the relative position that the balance weight of the VRV should be adjusted to. If the

point falls near the leftward border of a region, then the VRV balance weight should be adjusted to

it's minimum position. This corresponds to turning the balance weight screw as far counter-

clockwise as possible.

EXAMPLE:

An oil fired appliance firing at 1.0 gph where the CAS unit needs to be placed 30

equivalent feet from the intake hood.

From Diagram A or B, the point at 1.0 gph on the "Oil Firing Rate" scale and 30

equivalent feet falls in the "4 inch Duct, Hood, and Orifice Ring" region. The point

is in between the left and right boundary of the region. The left boundary is the

edge of the graph, the right boundary is the diagonal line that says "4 inch Duct,

Hood & Orifice Ring." Therefore, place the Orifice Ring into the inlet on the CAS

so that it sits on the ledge above the fan. It does not matter which way the Orifice

Ring is turned as long as it is pushed down against the ledge completely. Use 4"

diameter pipe to connect the vent hood and the CAS unit. Install a VRV and the

included 4x6 Increaser on top of the CAS unit and adjust the balance weight to

3/4 of the distance of it's full adjustment range from it's minimum setting. The

minimum setting is with the balance weight turned all of the way counter-

clockwise.

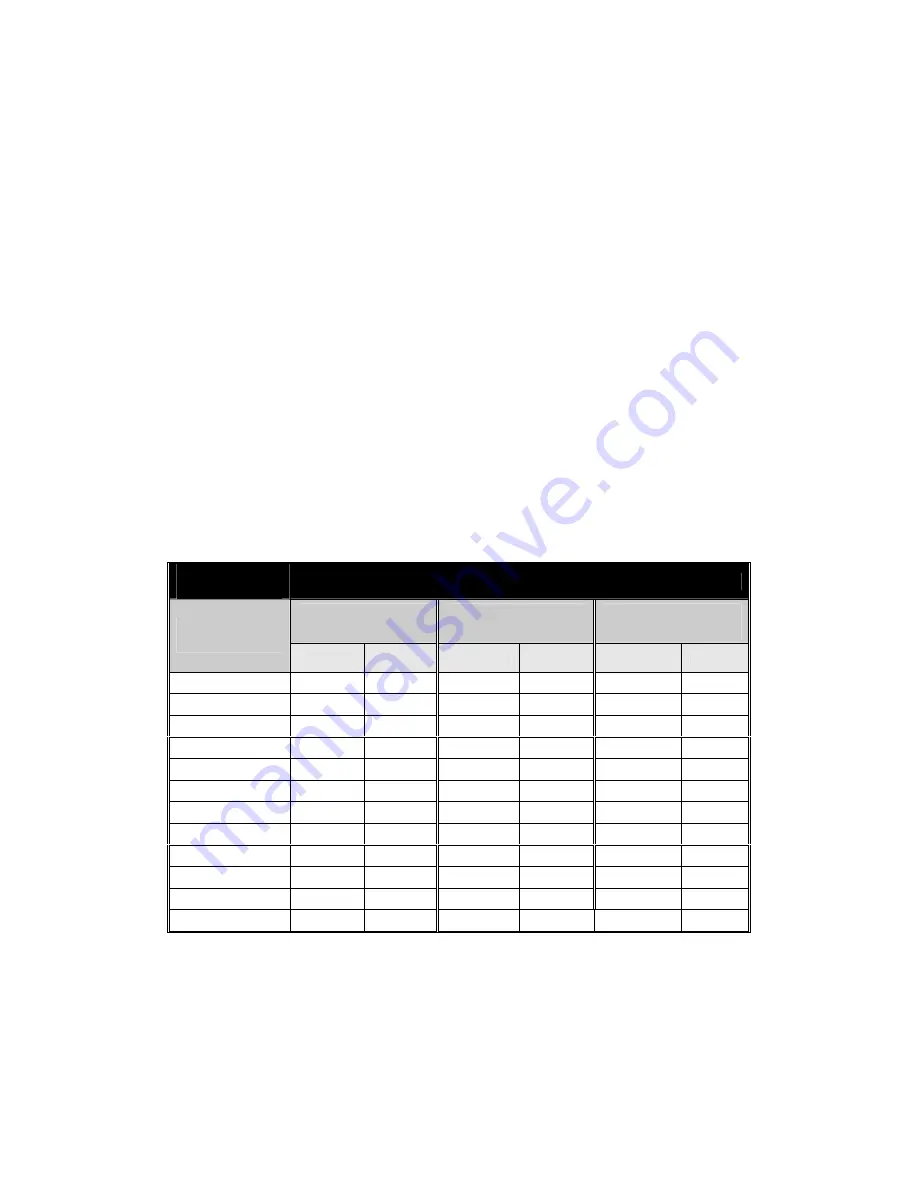

Total Input of

Appliance

Maximum Equivalent Feet of Installation

4” Duct And Hood

W/Restrictor

4” Duct And 4”

Intake Air Hood

6” Duct And 6”

Intake Air Hood

CAS-3

Oil (gph)

HI

LOW

HI

LOW

HI

LOW

0.50 300

300

300

300

300

300

0.75 300

300

300

300

300

300

0.90 300

220

300

220

300

300

1.00 174

108

232

118

300

300

1.25 99

48

152

63

300

300

1.35 52

14

102

32

300

300

1.55 20

NA

68

13

300

239

1.75 NA

NA

45

NA

300

150

2.00 NA

NA

16

NA

300

53

2.50 NA

NA

NA

NA

193

8

2.75 NA

NA

NA

NA

109

NA

3.25 NA

NA

NA

NA

56

NA

Table 1