SIDEWALL POWER VENTING SYSTEM

Model:

SWG-4G

ITEMS INCLUDED IN KIT

1 - SWGII-4HD Sidewall Power Venter

1 - CK-43F Control Kit (includes 4" MG-1 Barometric Draft Control)

1 - Installation Instructions

OPTIONAL COMPONENTS

PEK-4HD Extension Kit. For installations in walls over 8" thick.

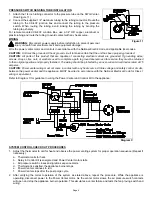

GENERAL SYSTEM INFORMATION

Designed for operation with natural gas and LP gas.

1. The thermostat calls for heat and energizes a relay which activates the power venter. After

the venter motor has come up to speed, the pressure switch closes. This closes the circuit

to the burner and allows the burner to fire.

2. After the heating requirement has been satisfied, the thermostat circuit will open and de-

activate the burner.

3. The power venter operates for a period of time after the burner has shut off to purge

remaining flue gases.

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

WARNING:

Bodily injury can result from high voltage electrical components, fast moving fans, and combustible

gas. For protection from these inherent hazards during installation and servicing, the electrical supply must be

disconnected and the main gas valve must be turned off. If operating checks must be performed with the unit

operating, it is the technicians responsibility to recognize these hazards and proceed safely.

Summary of Contents for 46334800

Page 10: ...Page 10...