Page 4

CONNECTING POWER VENTER TO APPLIANCE

The venting system should be installed and supported in accordance with the National Flue Gas Code, ANSI Z223.1,

CGA Standards B149.1-M91, B149.2-M91, or in accordance with any local codes. A vent pipe connector shall be

supported for the design and weight of the material employed, to maintain clearances, prevent physical damage and

separation of joints.

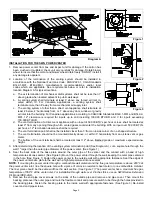

If mounting venting system near combustible materials, refer to Diagram B for allowable installation clearances. Always

check local code requirements for code restrictions.

Route the vent pipe from the appliance to the power venter using the minimum number of elbows necessary. The

horizontal section of the vent pipe should have a slight upward slope from the appliance to the power venter. For

clearances to combustible materials, multiple appliance venting, and other installation requirements, refer to the National

Fuel Gas Code ANSI Z223.1, CGA Standards B149.1-M91, B149.2-M91, and/or any applicable local codes or appliance

manufacturer's installation instructions.

Table 3

INSTALLATION CLEARANCE WITH SINGLE WALL VENT PIPE

DOUBLE PIPE SYSTEM

SINGLE PIPE VENTING SYSTEM

Allowable Inlet Temperature

Clearance (A)

Allowable Inlet Temperature

Clearance (A)

400°F Or Less

1/2” Minimum

400°F Or Less

1/2” Minimum

400°F To 550°F

1” Minimum

400°F To 550°F

1” Minimum

400°F To 550°F

1/2” Minimum

With Sheet Metal Liner

400°F To 550°F

1/2” Minimum

With Sheet Metal Liner

NOTE:

Vent pipe joints should be secured with at least three sheet metal screws.

Use a PEK series extension kit or follow installation method below for a double pipe system. When the outer pipe of the

SWG is extended over the inner pipe, use the double pipe guidelines for determining clearances.

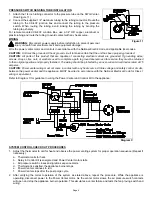

INSTALLATION USING TYPE B VENT PIPE

1. Using a hand crimper or a like device, crimp the inner pipe of the SWG power

venter approximately 1" long. (See Figure 4)

2. Attach the vent pipe over the crimped end of the SWG power venter inner pipe.

3. Secure the vent pipe to the SWG power venter inner pipe with at least (3) three

#8 sheet metal screws. Pre-drilling the holes through both pipes will allow easi-

er fastening.

Diagram B

Figure 4

Summary of Contents for 46334800

Page 10: ...Page 10...