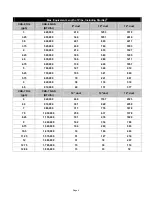

DIAGRAM A

CAS-6 (FAN + STARKAP SK-10) SIZING CHART

MAX. EQUIVALENT FEET OF PIPE

0.0

25.0

50.0

75.0

100.0

125.0

150.0

175.0

200.0

400

600

800

1000

1200

INPUT FIRING RATE (BTU/H x 1000)

#2 OIL = 140,000 BTU/GALLON

E

Q

UIV

A

LE

NT LE

NGTH OF P

IP

E

(ft.)

2.90

3.90

4.90

5.90

6.90

7.90

OIL INPUT FIRING RATE, GPH

12"

PIPE

10"

PIPE

6"

PIPE

8"

PIPE

6" DUCT

REGION

8" DUCT

REGION

10" DUCT

REGION

12" DUCT

REGION

Diagram A

DIAGRAM B

CAS-7 (FAN + STARKAP SK-12) SIZING CHART

MAX. EQUIVALENT FEET OF PIPE

0.0

25.0

50.0

75.0

100.0

125.0

150.0

175.0

200.0

800

1000

1200

1400

1600

1800

2000

INPUT FIRING RATE (BTU/H x 1000)

#2 OIL = 140,000 BTU/GALLON

EQUIVALENT LENGTH OF PIPE

5.7

6.7

7.7

8.7

9.7

10.7

11.7

12.7

13.7

OIL INPUT FIRING RATE, GPH

12"

PIPE

10"

PIPE

8" PIPE

14"

PIPE

8" DUCT

REGION

10" DUCT

REGION

12" DUCT

REGION

14"

DUCT

REGION

Diagram B

Page 3

Summary of Contents for 46371700

Page 7: ...Figure 7 Figure 8 Page 7...

Page 8: ...Figure 9 Figure 10 Page 8...

Page 9: ...Figure 11 Figure 12 Page 9...

Page 11: ...Page 11...