Page 10

Figure 10

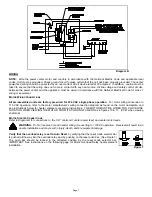

Figure 11

REPLACEMENT PARTS

Should the motor or blower wheel need replacing, the following replacement items are available. The Repair Motor

Assembly contains the Motor and Blower Wheel factory assembled to a mounting bracket.

PART NUMBERS

MODEL

REPAIR MOTOR ASSEMBLY BLOWER WHEEL

SWG-10

46414001

46408200

SWG-12

46414002

46408300

SWG-14

46414003

46408400

REMOVAL AND INSTALLATION OF THE SWG SERIES POWER VENTER MOTOR

ASSEMBLY

R

EMOVAL

1. Disconnect power to the venter and lock out the source appropriately.

2. Remove the motor enclosure cover.

3. Disconnect the motor wiring and flex conduit from the motor. (See Figure 10)

4. Using a nut driver or 1/4" drive deep socket, remove the six #8-32 lock nuts

attaching the wheel cover and heat shield to the venter body. (See Figure 12)

5. While supporting the motor assembly, remove the (3) 3/8" nuts and washers

attaching the assembly bracket to the venter, leaving the uppermost nut for last.

Carefully remove the motor assembly from the venter body, taking care to avoid

damaging the blower wheel or dislodging balancing weights.

6. Temporarily replace the motor enclosure cover if the unit is to be reassembled at a

later time.

I

NSTALLATION

1. Verify that power is disconnected to the venter motor leads and that the source is

locked out appropriately.

2. After inspecting the motor and blower wheel for shipping damage, grasp the motor

assembly and carefully insert the blower wheel into the venter body, using caution to

avoid damaging the wheel or displacing balancing weights. Grasp the wheel heat

shield and guide it onto its mounting studs, then guide the motor bracket onto its

three mounting tie rods. (See Figure 11) While supporting the motor, place a lock

washer and nut on the uppermost tie rod end and fasten finger tight. The motor

assembly will now 'hang' by the uppermost tie rod and may be released.

3. Place the remaining (2) lock washers and nuts on their respective tie rods and fasten

finger tight.

SWG Repair

Motor Assembly

Blower

Wheel

Flex Conduit

Knockout

Mounting

Tie Rod

Cooling

Fan Cover

Summary of Contents for 46413900

Page 12: ...Page 12 P N 46413900 09 01 ...