29

Air Flow Balancing using the Door Ports

FC155HRV & FC200HRV only

Door balancing ports (not on all models) are designed to be used in

conjunction with a Magnehelic Gauge or Digital Manometer to

measure the Stale and Fresh airflows for balancing.

Step 1

Prepare the air flow measuring device (i.e. Magnehelic Gauge or

Digital Manometer) by connecting the hoses to the low and high

pressure side of the gauge.

Step 2

Insert the hoses into the rubber fittings from the optional Door Port

Adapter Kit (part # 99-182). Use light pressure and rotate until

fitting is snug. Do not extend the hose past the rubber fitting.

Step 3

Open the HRV Door. Remove the 4 Door Port Covers by carefully

pushing them out from the back side of the door (use the blunt end

of a large drill bit etc.).

Step 4

Close the HRV Door. Initiate power and operate the HRV on high

speed. Operate the forced air system on high speed (if the HRV is

connected to the forced air system) .

Step 5

Insert the 2 rubber fittings from the gauge to the STALE AIR

Balancing Ports (upper right and lower left). Seal the FRESH AIR

Balancing Ports (upper left and lower right) with tape. Record your

reading.

Step 6

Insert the 2 rubber fittings from the gauge to the FRESH AIR

Balancing Ports (upper left and lower right). Seal the STALE AIR

Balancing Ports (upper right and lower left) with tape. Record your

reading.

Step 7

Refer to the "Airflow Reference Chart" for your model and

determine the FRESH AIR and STALE AIR flow rates (the chart is

located on the lower portion of this page).

Step 8

Damper down the higher airflow and repeat Steps 5 to 7 as required

until both airflows are identical (balanced).

Step 9

Remove the tape and rubber fittings and reinstall the 4 Door Port

Covers.

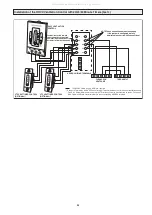

MODEL 200

0 230

153

156

Manometer

Reading

Airflow Numbers

(CFM)

(in. w.g.)

0.100

98

91

0.110

102

96

0.120

107

101

0.130

111

107

0.140

115

112

0.150

120

117

0.160

124

122

0.170

128

127

0.180

133

132

0.190

137

137

0.200

141

142

0.210

145

147

0.220

149

152

0 230

.

153

156

0.240

157

161

0.250

161

166

0.260

165

171

0.270

169

175

0.280

173

180

0.290

177

184

0.300

181

189

0.310

185

193

0.320

189

198

0.330

192

202

0.340

196

207

0.350

200

211

0.360

203

215

MODEL 155

0 180

142

129

Airflow Numbers

(CFM)

Pressure

(in. w.g.)

Fresh Air Stale Air

0.100

93

80

0.105

96

83

0.110

99

86

0.115

102

89

0.120

105

92

0.125

108

96

0.130

111

99

0.135

114

102

0.140

117

105

0.145

120

108

0.150

123

111

0.160

130

117

0.170

136

123

0 180

.

142

129

0.190

148

135

0.200

154

141

0.210

160

147

0.220

166

154

0.230

172

160

0.240

178

166

0.250

184

172

0.260

191

178

0.270

197

184

0.280

203

190

0.290

209

196

0.300

215

202

0.310

221

209

Pressure

Manometer

Reading

Fresh Air Stale Air

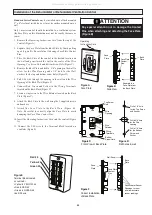

Magnehelic Gauge hoses connected to

STALE AIR balancing ports

Illustration of measuring STALE airflow using a Magnehelic Gauge.

Magnehelic Gauge hoses connected to

FRESH AIR balancing ports

Illustration of measuring FRESH airflow using a Magnehelic Gauge.

Fresh Air

Balancing Ports

(top-left,

bottom-right)

Stale Air

Balancing Ports

(top-right,

bottom-left)

Illustration of a door with door ports

Airflow Reference Charts

FC200HRV

FC155HRV

All manuals and user guides at all-guides.com