www.fi eldcontrols.com

Please retain these instructions after installation.

This device MUST be installed by a qualifi ed agency in accordance with the manufacturer's installation instructions. The defi nition of

a qualifi ed agency is: any individual, fi rm, corporation or company which either in person or through a representative is engaged

in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all the

precautions required, and has complied with all the requirements of the authority having jurisdiction.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

Installation Date:

Installed By:

Phone:

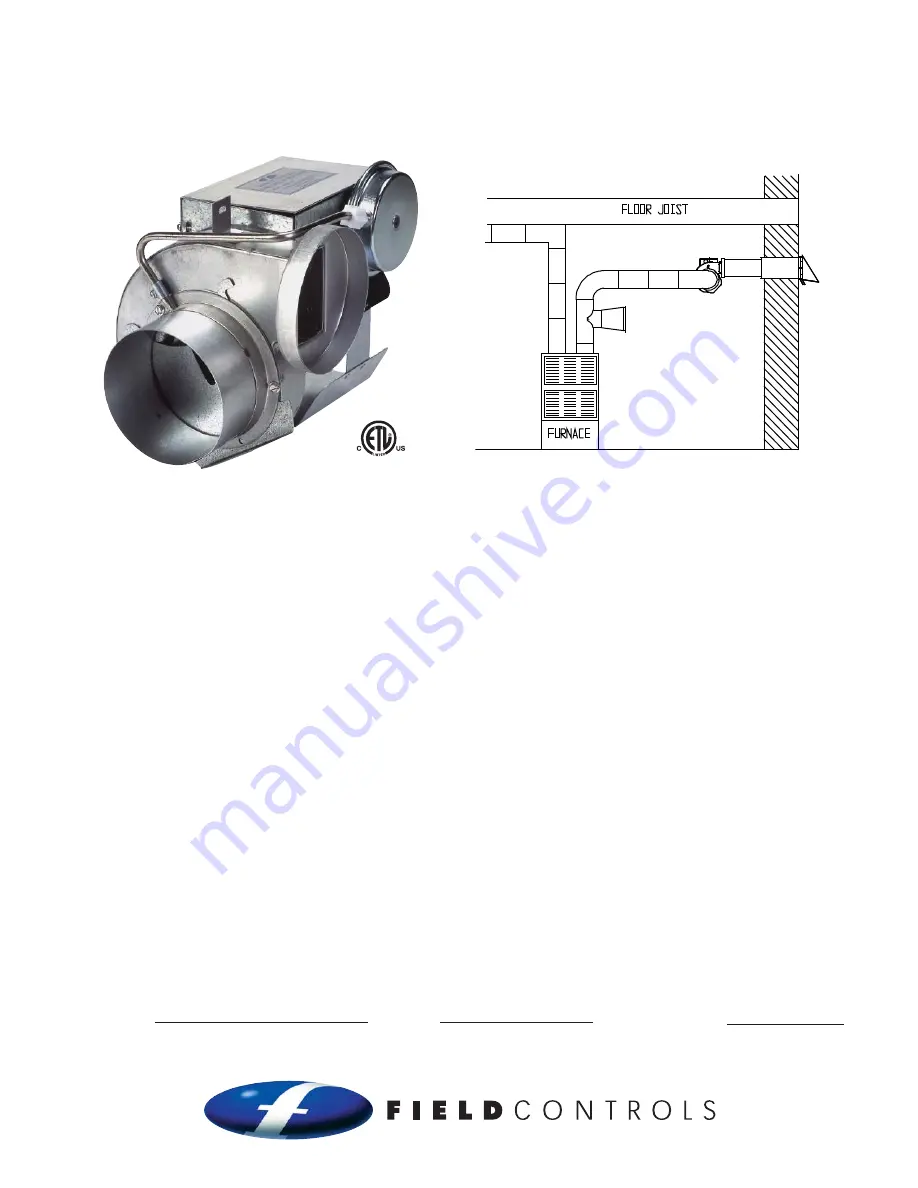

POWER VENTER

Model: PVE Series

CONTENTS

Page

Typical Venting System Components...............................................

System Operation..............................................................................

Power Venter Sizing...........................................................................

Installation Safety Instructions..........................................................

Installation of Power Venter...............................................................

Connecting Power Venter to Appliance..........................................

General Wiring Instructions..............................................................

Airfl ow

Adjustments..........................................................................

General Installation Inspection.........................................................

M aintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement

Parts List.......................................................................

System Operational Information......................................................

2

3

3,4

5,6

6,7

7

7

8

8,9

9,10

10

11