Note: Settings for this product need to be determined by

user since factors such as coarseness and density of

“material used” affect the spread rates See page 3 “rate

material used affect the spread rates. See page 3 rate

worksheet” to calculate approximate spread rates.

When Rate settings are not available, follow these guidelines to calculate

spread rates:

On the bag of material to spread

o

ill find recommended spread rates

s all in

On the bag of material to spread, you will find recommended spread rates, usually in

terms to

the effect of: so many pounds will cover so many sq. ft.

Read these steps, then refer to the guide (worksheet page 3)

1.Determine how much material to apply per 1,000 sq. ft.

1.Determine how much material to apply per 1,000 sq. ft.

2. Measure off a distance of 50ft, preferably on a paved area (ie: parking lot)

3. Weigh out enough material from bag to fill hopper ½ full (recommend at least ½ full

hopper)

Record weight for later.

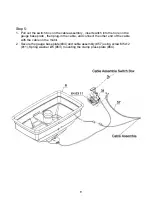

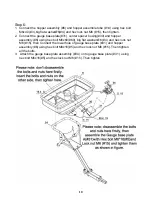

4. Set the stop at position with opening of hopper at position you feel appropriate.

5. Now with hopper ½ full, bring vehicle to desired speed before start line of your 50 ft test

area.

When you arrive at start line, turn on spreader, then off at finish line

6. Stop the vehicle and note the width of spread path from your test run.

7. Repeat if necessary; Then empty remaining material from hopper back to your weighing

device and record new weight.

8. Be sure to record your results, see below guide on page 3.

2