EN

16

FZS 5025-B

8. PREPARING FOR OPERATION

IMPORTANT:

Follow instructions for preparing the fuel mix! Not following these instruction may damage the engine! Do not

use fuel that has been stored for longer than two months. A fuel mix stored for longer than two months will cause

problems at start up and lower engine performance. If the fuel mix is stored for longer than two months, it should

be removed and new fuel must be used.

Points to check before starting work

1. Check whether any screws, nuts and installation elements are loose. Tighten any loose screws.

2. Check whether the air fi lter is dirty. Prior to starting work, remove all dirt from the air fi lter.

3. Make sure that the plastic head guard and the blade is securely fastened in place.

4. Check the fuel tank for leaks.

5. Check the blade or the string trimmer head for damage.

9. SAFETY WORKING WITH BRUSH CUTTER

USING THE SHOULDER HARNESS

1. Assemble and adjust the shoulder harness and belt, as shown.

2. Adjust the shoulder-harness button, and move the hook to your waist, then adjust the belt (If there is a belt).

3. Hang the latch tab on the harness hook.

4. If the brush cutter does’t balance, then adjust the harness hanger, and the handlebar, until it balances.

WARNING CAUTION

The hook is situated at your right hip,and the quick-release latch is situated at the outside.

Fig. 11

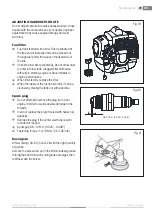

SHOULDER

HARNESS

HOOK

HOOK

QUICK-RELEASE

LATCH

SHOULDER

HARNESS

BUTTON

BELT

GROUND

TRIMMER

CUTTING

ATTACHMENT

ALUMINIUM

PIPE

HARNESS

HANGER

LATCH

TAB

FULL

QUICK-RELEASE LATCH

5. To quickly detach the brush cutter from the harness, pull the quick-release latch tab upward;

6. Insert the latch tongue in the slot of the quick-release latch to reattach the brush cutter to the harness.

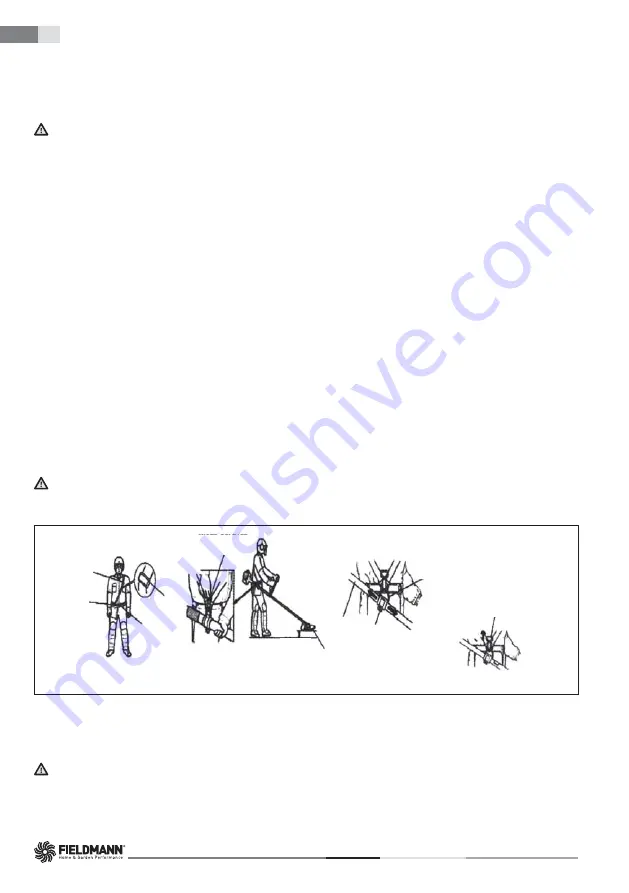

WARNING DANGER

Before using, please check the shoulder harness and confi rm it is OK. Encounter danger, please stop the brush

cutter immediately,and pull the quick-release latch tab, the brush cutter will be depart from your body.

Preparing for operation | Safety working with brush cutter