11)

Gently lift and lower hammer up & down mast, using full ram stroke to purge air from hydraulics. After this is

achieved position hammer opposite handle bracket.

12)

Slide post cap up to hammer & hook chain to hammer lug.

13)

Refit storage leg bracket to base of mast to prevent post cap detaching.

14)

Disconnect post cap chain. Raise hammer halfway up mast. Utilizing hydraulic control handle, allow hammer

to drop 300mm & release handle. Hammer should stop without "bounce" If hammer bounces, or "creeps” down

mast, adjust port relief valve.

Setting the Port Relief Valve:

The

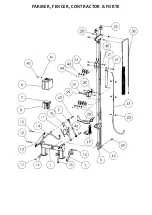

Port relief valve adjusting screw is located on the underside of control

bank to the rear and right of hammer control slice (as pictured Item 2). To adjust, remove silver hex cap to expose slot

on top of valve. With flat screw driver, adjust in 1/8 turn increments clockwise until the correct setting is achieved.

The point in ‘setting’ the Port relief valve is in order to ensure a safe / cushioned hammer stop is in the hydraulic

system so that an abrupt / harsh ‘snap stop’ to the hydraulic line is not happening when the valve handle is returned

to centre when the hammer is falling down the mast. It is most likely that due to differing tractor hydraulic

pressures, flow rates, differing hammer weights etc that this adjusting will need to be fine tuned on initial fitment to

the tractor or the initial delivery of the machine.

a)

Wind in to stop the hammer ‘creeping’ down mast (if it is open too much, the oil bypasses the spring loaded

valve and the hammer will slowly slide down the mast)

b)

Hammer stops with a soft cushioned stop rather than ‘bounce’. (if it stops with a bounce, the port relief is

set too tight and will not be working)

Port relief valve

Pt No. 116025.03

Item 1 – Valve control lever kits (refer to parts dept for spares available) Handle ‘kit’ - pt number 116025.01

Item 2 – Port relief valve – Pt No 116025.03

Item 3 – Rear blanking plug to remove for closed circuit valve bung fitting (as per Instruction 8)

IMPORTANT TROUBLE SHOOTING NOTE REGARDING HAMMER CREEP OR PORT RELIEF

SETTING PROBLEMS:

If you find that the hammer continues to fall down even after the adjustments as detailed

above have been made, it is very likely that dirty or slightly contaminated hydraulic oil has damaged the fine ‘seat’ in the

port relief valve. If this is damaged, your valve will need to be returned to Fieldmaster for re-seating of this port relief

valve. This is NOT a warranty failure and will be caused by contamination in the hydraulic oil supply from the tractor (It

only requires a small amount of contamination in the oil to cause a leakage!) Before this conclusion, try ‘flushing’ the oil or

contamination through the port relief by jerking / pumping the port relief (stop / start the hammer with the port relief

adjusted in and out and several other positions in order to try and flush any contamin ation lodged in between the fine port

relief spring loaded seat) Failure to remedy this by doing this, will most likely mean that the port relief ‘seat’ has been

scoured or slightly worn thus allowing oil to bypass – this will cause the hammer to slowly creep down the mast even

when the valve handle is in spring centre (shut) position.

PREMATURE WIRE ROPE FAILURE OR SERIOUS INJURY COULD OCCUR IF RELIEF VALVE NOT SET

CORRECTLY