avoid skid marks and also in very dry conditions if the ground is reasonable skid wear

can be reduced with more pressure on the roller. However, individual conditions and

varying operators will find success sometimes in the varying of these conditions.

A finer adjustment can be achieved by lengthening or shortening the tractor top link

arm.

It is important that the top link arm is adjusted so that the skid runners are running

parallel with the ground. This will automatically give the mowing deck approximately

3/4” (19mm) ‘lead-in’ required for good mowing. This check should be made with

tractor and mower on level surfaces with mower in cutting position.

The best cutting performance will be gained when

operating at

540 RPM is

maintained.

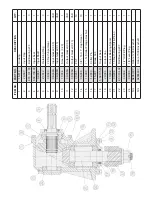

The Telescopic Drive Shaft

There is a wide range of tractors and the horizontal distance between the power take

off shaft and the drawbar varies considerably. A specific instruction for each would

require extensive research. However, taking for example the minimum and maximum

conditions, safe working lengths of the drive shaft are as follows:

Once the shaft is fitted to the machine or tractor a simple test should be carried out.

On raising and lowering the machine fully on the linkage arm, at no point of time

should the P.T.O. shaft be fully compressed. During the raise and lowering travel,

when the P.T.O. shaft is at the shortest length, allowance should be made for the shaft

to compress a further 40mm, but taking care that the shaft is not cut too short so that

at the longest point during travel has still got at least 100mm of contact with both

inner and outer tubes.

Ensure that both splined yokes are securely fastened to the splined shafts on both the

tractor P.T.O. and mower gearbox input shaft.

Routine Lubrication and Maintenance

1) Grease the sliding shaft and tube of the driveshaft every 20 working hours.

The

shaft should be pulled apart to ensure sufficient application of grease.

2) Grease the driveshaft cross and bearings every 10 working hours.

3) Check gearbox oil before use every time. Top up with EP 90 extreme

pressure or alternative.

Points to Remember

1) Fast forward speed leaves longer stubble. The slower the speed, the better the

finish.

2) Maintain skids parallel to each other by always adjusting bolts to same height holes

each side.

3) High P.T.O revs. will slightly lift blades, which will cut higher than expected.