FK-400-000 5 I56-3883-003

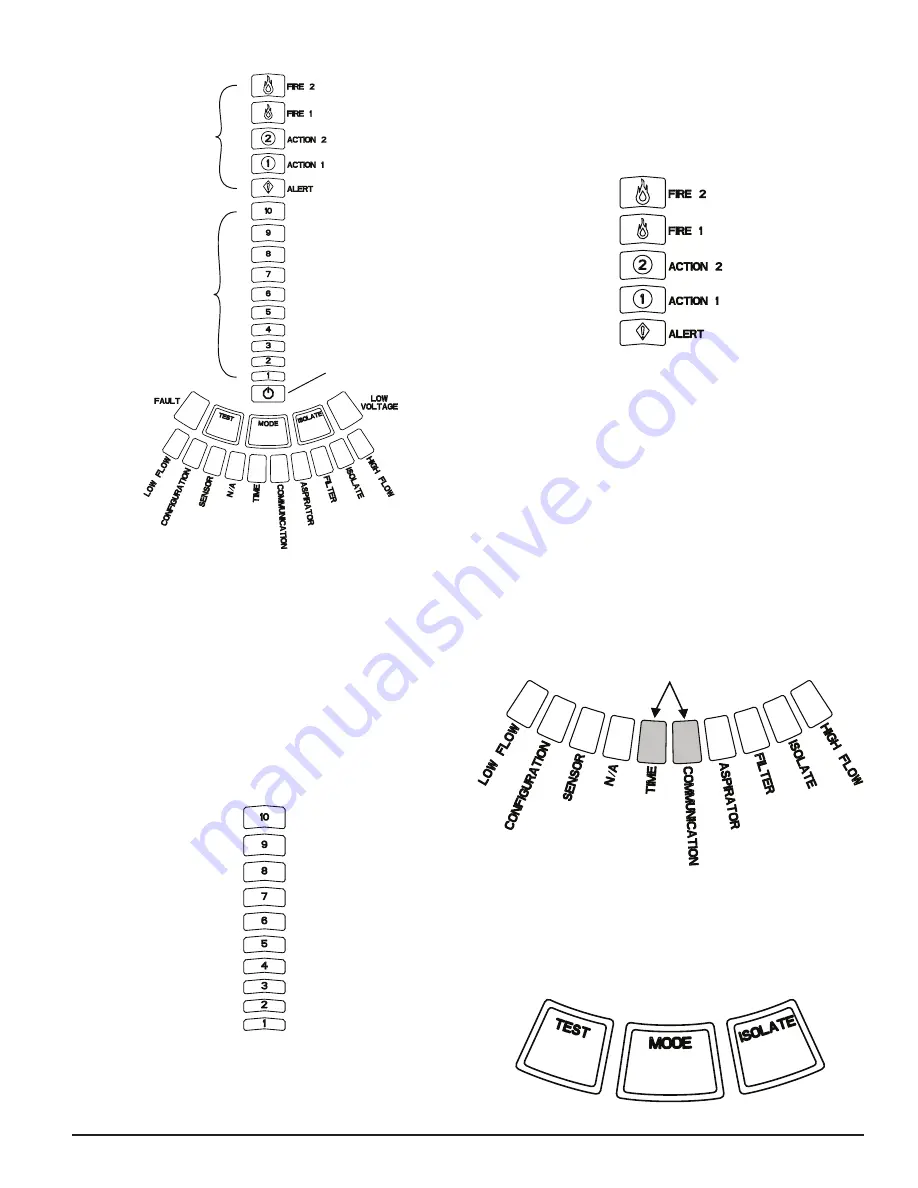

FIGURE 5. PARTICULATE LEVEL DISPLAY

ASP-09

FIGURE 6. ALARM LEVEL DISPLAY

ASP-10

USER INTERFACE CARD INSTALLATION

The user interface card must be installed on the front panel of the FAAST

aspirating smoke detection system. For installation, first slide the card into

the bottom pocket, then beneath each of the mounting tabs. If necessary,

use a flathead screwdriver to gently press the card in place beneath each of

the mounting tabs. The card is moderately flexible to allow for some bending

during installation. The user interface card is available in various languages.

PARTICULATE LEVEL DISPLAY

The particulate level display, shown in Figure 5, consists of ten amber LEDs

that correspond to the current level of the particulate detected. The LEDs il-

luminate in order from Level 1 to Level 10, starting from the bottom of the

display and moving up as the particulate level increases. Each LED represents

a ten percent increase in the particulate level necessary to reach the user pro-

grammable level.

ALARM LEVEL DISPLAY

The Alarm Level Display consists of five red LEDs that correspond to the cur-

rent alarm level, shown in Figure 6. These LEDs are located directly above the

Particulate Level LEDs. They illuminate sequentially upward as the severity of the

alarm increases.

AIR FLOW/FAULT DISPLAY

The FAAST system uses ultrasonic airflow sensing and displays the status in

real time on the User Interface. The air flow/fault display consists of 10-bi-

color LEDs and operates in one of two modes. A default warning occurs when

airflow increases or decreases by 20% or greater. The green segments indicate

how close the current air flow is to either of these thresholds. During normal

operation two adjacent indicators are green and correspond to the current air-

flow entering the detector. When airflow is at a balanced level the two green

segments are centered on the graph at levels 5 and 6, see Figure 7. As air-

flow rises and falls, the green segments move right and left accordingly. The

segment on the far left represents a decrease in airflow of 20%. Conversely,

movement to the segment on the far right represents an airflow increase of

20%. A flow fault occurs within 3 minutes of reaching either of these levels

and the minor fault relay is indicated. During a fault condition, the fault LED

as well as the corresponding high or low fault segment is lit in amber.

Labels

Detector faults are labeled adjacent to the indicators on the Air Flow Fault graph.

FIGURE 8. USER INTERFACE BUTTONS

FIGURE 7. BALANCED AIR FLOW

ASP11-01

USER INTERFACE BUTTONS

The user interface has three buttons, shown in Figure 8, that are used to op-

erate the unit. Functionality of these buttons are locked out by default from

the factory and require a passcode to enable them (refer to Passcode Access

section). The passcode can be programmed from the PipeIQ software tool.

GREEN LEDs

ASP14-01

FIGURE 4. USER INTERFACE DISPLAY

Alarm Level

Indicator

Particulate Level

Indicator

Power

Indicator

ASP08-02

These alarm levels are configured at default levels when shipped. Each of these

alarm levels can control a set of form C relay contacts. When an alarm level thresh-

old is crossed, the corresponding level LED illuminates and the relay activates a

signal. These alarm levels and associated relay outputs can be programmed for

either latching or non-latching operation, in addition to a programmable delay for

each level. The programmable ranges for each level are shown in Table 3.