16 |

P a g e

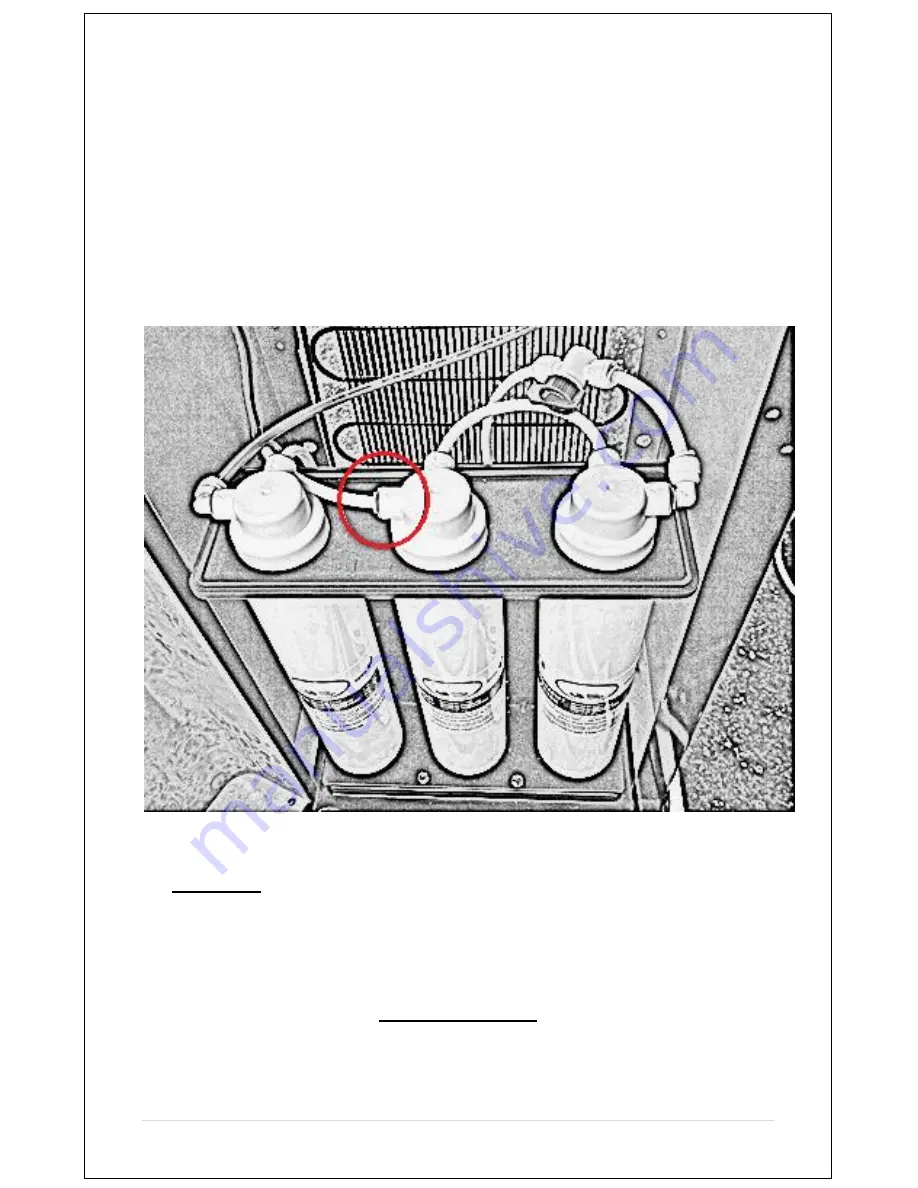

Disconnect the tube from the 2nd stage carbon filter (circle in figure

below) and place a cup or pan right underneath the hole to catch water.

Open ball valve inside the cooler 1/4-turn (handle in line with tube is

“on” and let water flow through filters into the bucket or pan to push out

air and carbon fines. When water runs clear, turn off ball valve and re-

connect the tube to the filter.

Turn on the water to the filter system by opening the ball valve inside the

cooler 1/4-turn (handle in line with tube is “on”). Check all connections

to assure there are no leaks.

Figure. 6

Filter configuration

model “F”

with cooler door opened

Tank Flush

Flush tanks out by draining all water through the (1) drain

plug located on the back of the cooler and drain water through the