4

On consignment of the machine

When the machine is consigned to the customer, an immediate check

must be performed to ensure all the material mentioned in the shipping

documents have been received and moreover to find out that the

machine has not suffered damage during transportation. If damage

has occurred, get the shipping agent to verify immediately the amount

and nature of the damage suffered and at the same time inform our

claim department. It is only by prompt action of this type that

compensation for damage may be successfully claimed.

Introduction

Any machine can work efficiently only when used properly and

maintained in fully efficiently working order. We therefore encourage

you to read this instruction manual thoroughly and to refer to it

whenever difficulties arise while working with the machine.

Additionally we inform you that our customer service in co-operation

with our agents are always at your complete disposal for any

questions or for direct intervention.

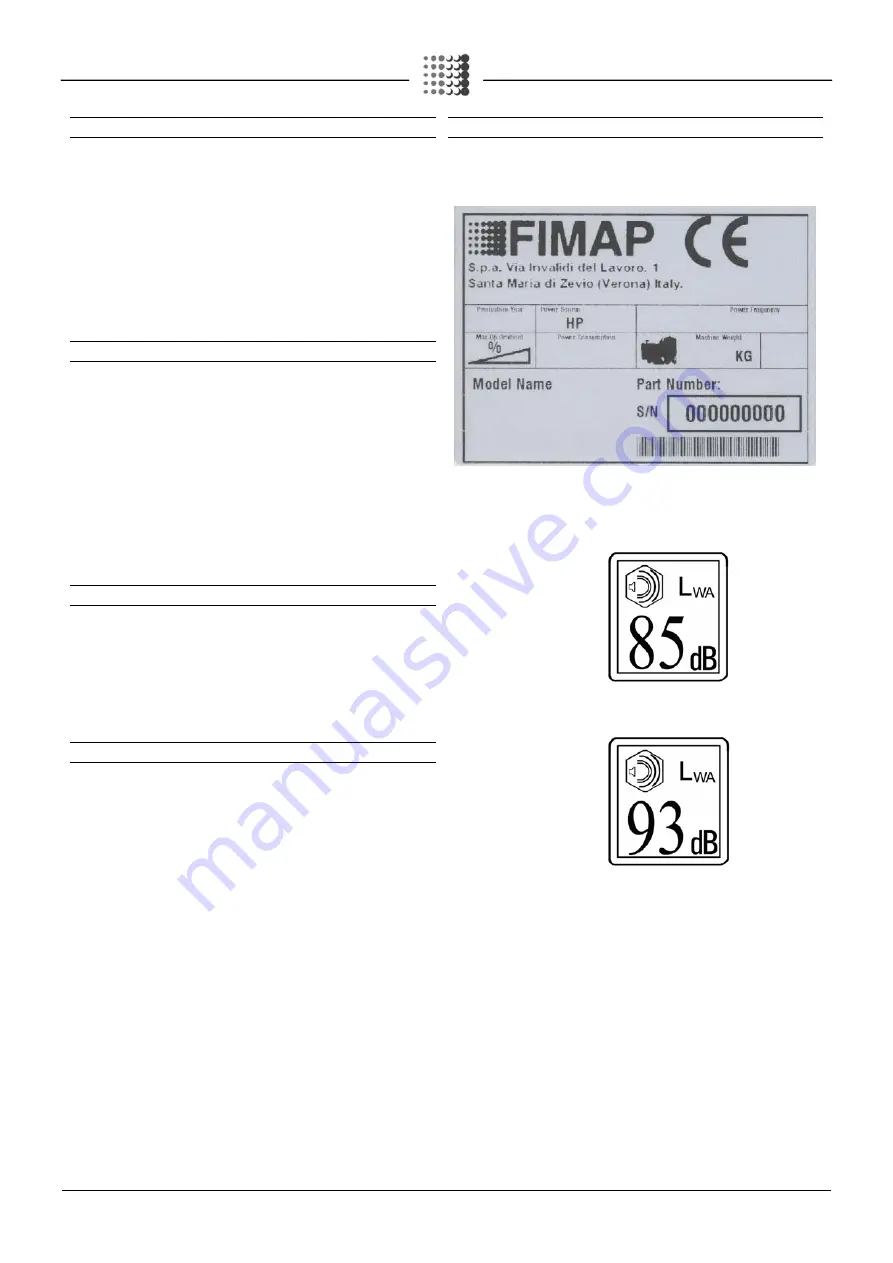

Data for identification

For Technical service or request of spare parts, cite always the model,

the version and the serials number whic is on the proper seial plate.

Technical description

FS50 H-HT is a sweeping machine operated by a petrol engine and it

is meant for cleaning both indoor and outdoor surfaces paved with

tiles, cement or asphalt.

FS50 B-BT is a battery-powered electric sweeping machine used to

clean both interior and exterior surfaces paved with concrete and

asphalt or covered with tiles. It is designed to work on dry surfaces

but can also work on wet surfaces if the suction system is kept

closed.

Machines are provided with: a central brush to brush up and collect

dirt, a side brush for cleaning corners, a suction system with a filter to

prevent dust form being blown into the atmosphere and a dirt

collection bin.

Do not use the machines for other purposes but the above mentioned.

Serial number plate

FS50 B-BT

FS50 H-HT