13

MACHINE PREPARATION

3.

"ECO" function button.

4.

Vacuum motor control button.

5.

“AUTO” function button.

6.

Reverse button

7.

Proportional solenoid valve control button.

8.

Brush coupling/uncoupling button.

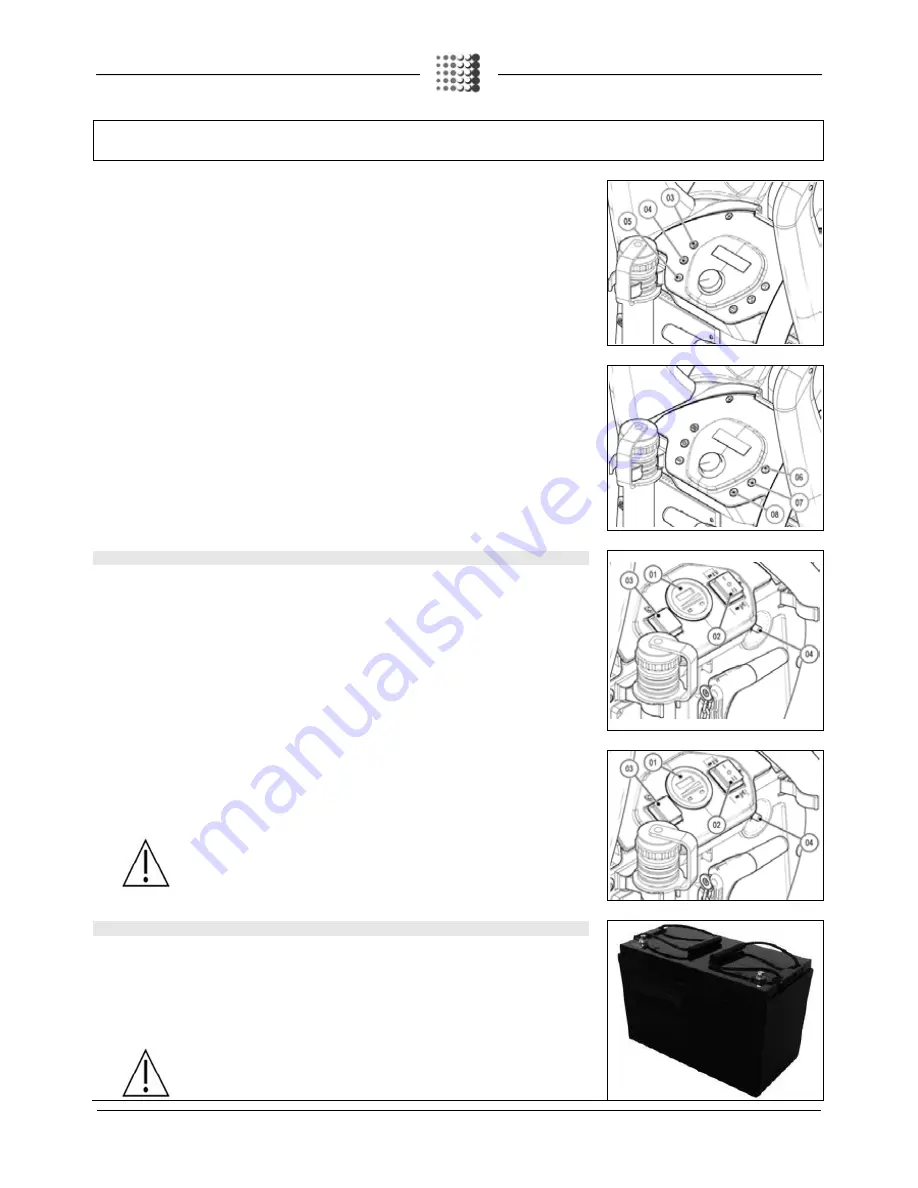

8. CONTROL PANEL COMPONENTS (VERSION BB)

The control panel components are identified as follows:

1.

Level indicator for battery/hour meter.

2.

Main switch with three positions:.

Position “I”: Switch in “ON + SOLENOID VALVE ON” position activates the brush motor and the

solenoid valve

Position “0”: Switch in “OFF” position interrupts the power supply in the machine's electrical system.

Position “II”: Switch in “ON + SOLENOID VALVE OFF” position activates the brush motor but not the

solenoid valve

3.

Vacuum motor control button.

Position-01: Switch in “ON - VACUUM” position activates the vacuum motor

Position-02: Switch in “OFF - VACUUM” position deactivates the vacuum motor

4.

Brush uncoupling switch.

WARNING: From this point on in the document the positions of the main switch (02)

will be identified with “I or 0 or II”.

WARNING: from this point on in the document, the positions of the vacuum motor

control switch (03) will be identified with “Pos.-01" or "Pos.-02”.

9. TYPE OF BATTERY

Power to the machine must be supplied by two sealed traction batteries with gas recombination or gel

technology. The batteries must meet the requirements laid out in the norms: CEI EN 60254-1:2005-12 (CEI

21-5) + CEI EN 60254-2:2008-06 (CEI 21-7).

For optimum performance, the use of two 12V 77Ah/C5 batteries is recommended (size: 330 mm x 169 mm x H233mm

each with a weight of 27 kg), or two 12V 75Ah/C5 batteries (size: 259 mm x 169 mm x H2227mm each with a

weight of 25 kg).

WARNING: If batteries with weights or dimensions differing from those advised above

are used, the machine performance could vary considerably.