47

CHOOSING AND USING THE BRUSHES

POLYPROPYLENE BRUSH (PPL)

Used on all types of floor, it has good resistance to wear and tear and hot water (no greater than 60°C). PPL is non-hygroscopic and therefore retains its

characteristics even when working in wet conditions.

NYLON BRUSH

Used on all types of floors. Excellent resistance to wear and tear, and hot water (even over 60°C). The nylon is hygroscopic and so tends to lose its

characteristics over time when working in wet conditions.

ABRASIVE BRUSH

The bristles of this type of brush are charged with highly aggressive abrasives. It is used to clean very dirty floors. To avoid floor damage, work only with the

pressure strictly necessary.

THICKNESS OF THE BRISTLES

Thicker bristles are more rigid and are therefore used on smooth floors or floors with small joints.

On uneven floors or those with deep joints, it is advisable to use softer bristles which can enter the gaps more easily.

Remember that when the bristles are worn and therefore too short, they will become rigid and are no longer able to penetrate and clean deep down, also

because, like with over-large bristles, the brush tends to jump.

PAD HOLDER

The pad holder is recommended for cleaning shiny surfaces.

There are two types of pad holder:

1.

The traditional pad holder is fitted with a series of anchor points that allow the abrasive floor pad to be held and dragged while working.

2.

The CENTER LOCK type pad holder not only has anchor points, but also a snap-type central locking system in plastic that allows the abrasive floor

pad to be perfectly centred and held without any risk of it becoming detached. This type of holder is especially suitable for machines with several

brushes, where the centring of the abrasive floor pads is difficult.

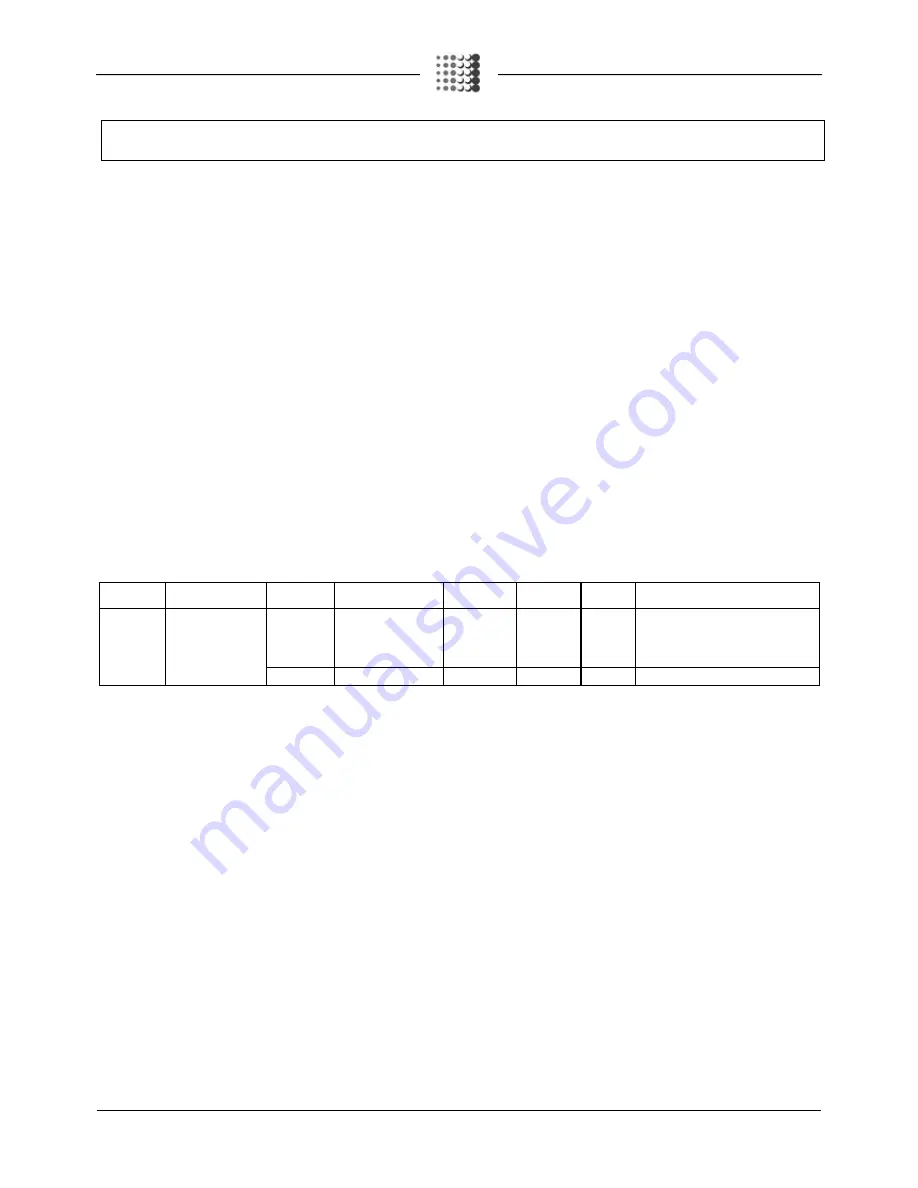

TABLE FOR CHOOSING THE BRUSHES

Machine No. of brushes.

Code

Type of bristles

∅

Bristles

∅

Brush Length

Notes

iMx

1

404654

405631

404653

405632

PPL

PPL

PPL

ABRASIVE

0.3

0.6

0.9

1

495

-

BLUE BRUSH

WHITE BRUSH

BLACK BRUSH

BRUSH

405527

-

-

500

-

PAD HOLDER