ADJUSTMENT

AND

INSPECTION

MAGNA 65-70-75-83

Doc. 10004978

Issued 27/03/2008

Rev. 00

P a g .

3 d i 19

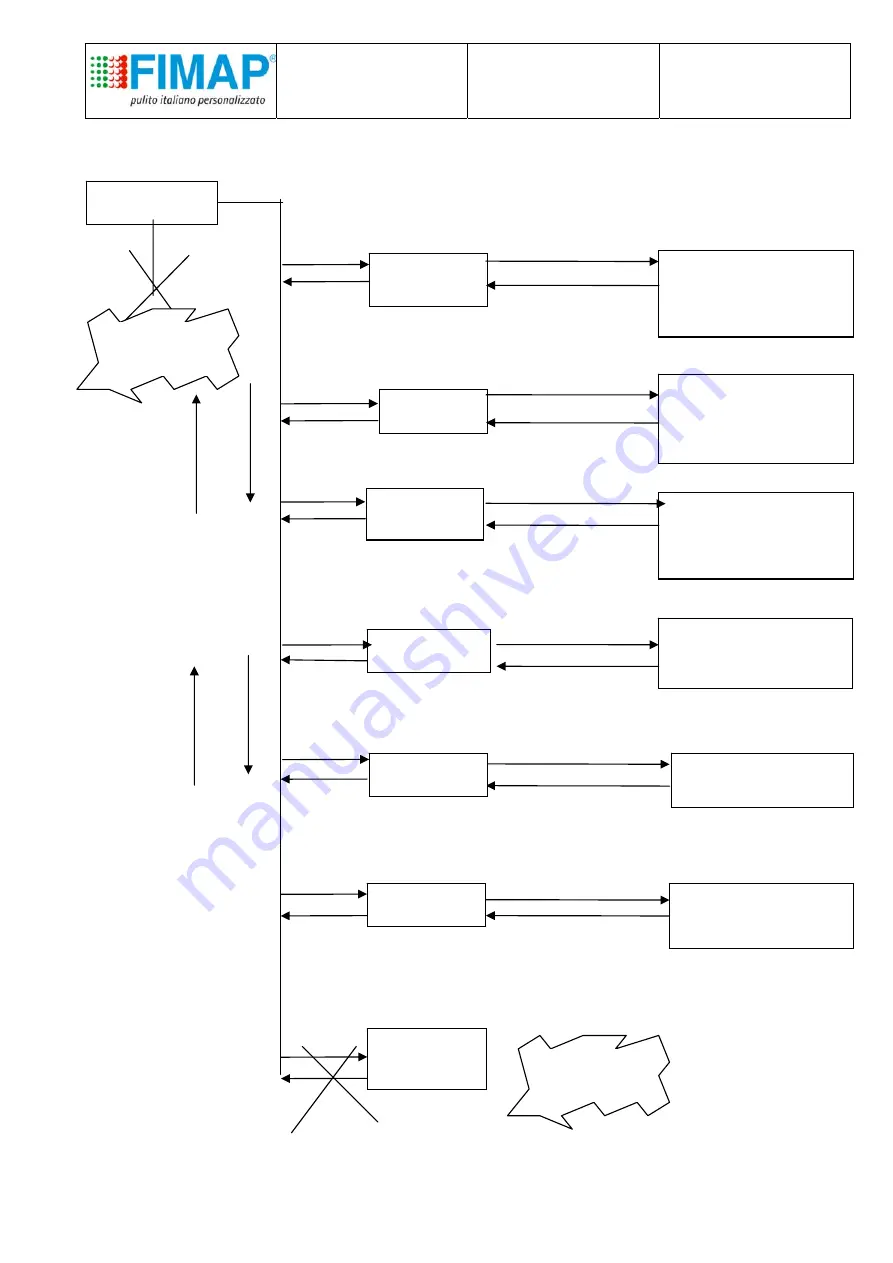

Flow chart of the console

HEADING

PROGRAM

TESTER

LIST OF PARAMETERS

ROLL to select

PARAM SET to change

enter

out

enter

out

DO YOU WANT TO

SAVE DATA ?

ENTER = change

OUT= no change

enter

enter

TEST LIST OF VALUES

to test

ROLL to select

PROGRAM

VACC

enter

out

Program for setting

pedal accelerator

MOTOR data

enter

out

R

O

L

L

R

O

L

L

enter

out

enter

SAVE

enter

out

LIST OF free locations

Write on on a FREE

location

enter

enter

RESTORE

enter

out

LIST OF locations

(programs) to load on

the chopper card

Enter: Are you sure ?

ENTER = restore

OUT= no restore

out

Out: Are you sure?

ENTER = change

OUT= no change

enter / enter

ALARMS

List of the last 5

alarms occurred

Out

This menù has

not to be

modified

This menù has

not to be

modified

Enter: Are you sure ?

ENTER = save

OUT= no save