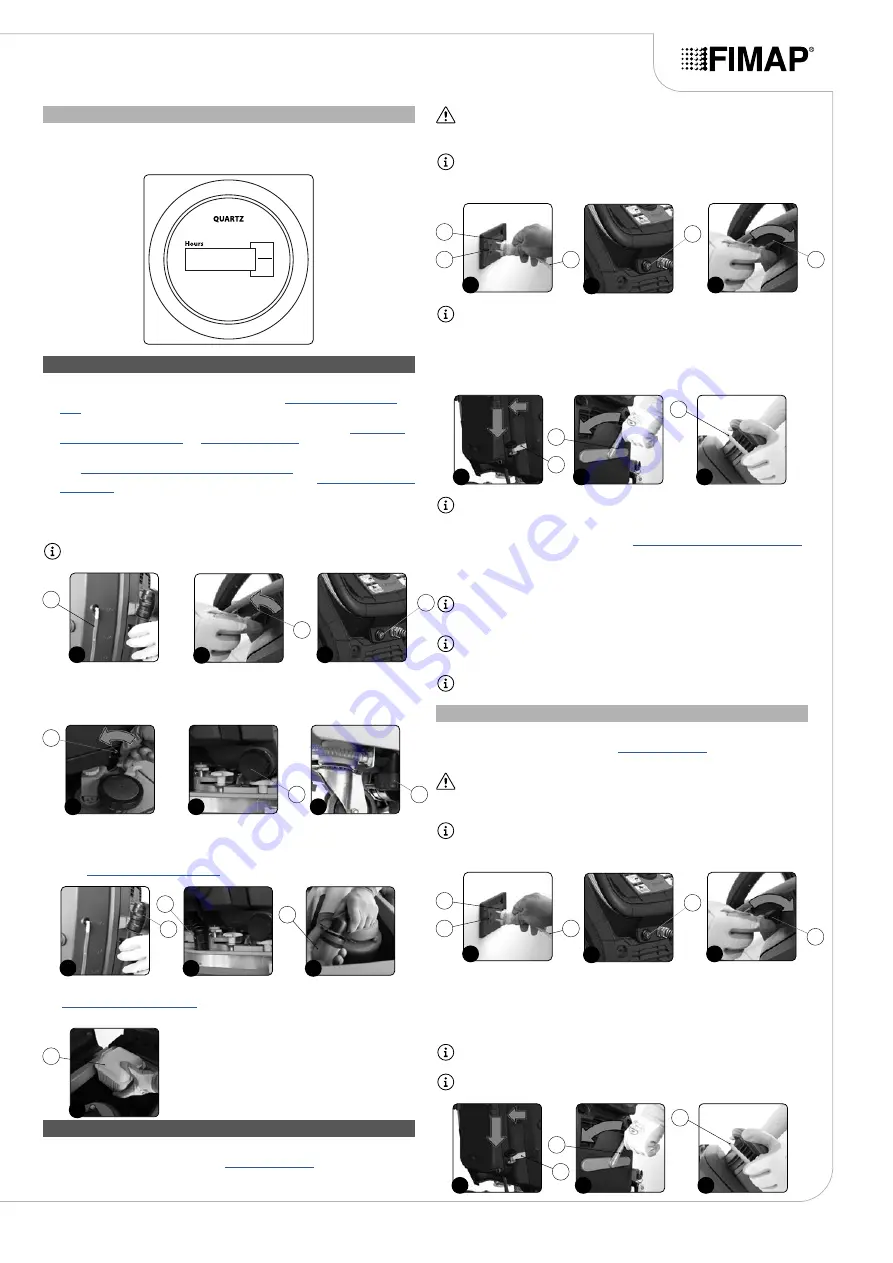

HOUR METER

The machine control panel contains the control display, which shows the total usage time. The numbers

before the letter “h” identify the hours, while the numbers before the letter “m” identify the tenths of an

hour (a tenth of an hour corresponds to six minutes). The flashing “:” symbol indicates that the hour

meter is counting the machine functioning time.

CURTIS

1

10

000000.0

PREPARING TO WORK

Before beginning to work, it is necessary to:

1. Make sure the recovery tank is empty. If it isn't, empty it (see “

2. For versions without FSS, make sure the amount of detergent solution in the solution tank is

suitable for the type of work to be carried out. If it isn't, fill the solution tank (see

"). Check the level tube (1) in

the rear left-hand part of the machine (

Fig.1

).

3. Check the rubber squeegee blades are in good working condition. If they aren't, replace them

(see “

REPLACING THE SQUEEGEE BODY RUBBER BLADES

4. Check the brush is in good working condition. If it isn't, replace it (see “

5. Check that the main key switch on the control panel is set to “0”. If necessary turn the key (2) to

the left (

Fig.2

).

6. Check that the main button switch on the control panel is set to “0”. If necessary press the button

(3) (

Fig.3

).

NB

:

if the LED in the button switch (3) is on it means that the switch is set to "I” (

Fig.3

). if the

LED in the button switch (3) is off it means that the switch is set to "0”.

1

1

2

2

3

3

7.

Check that the water tap is fully open, the water adjustment knob (4) must be turned fully in the

direction shown by the arrow (

Fig.4

).

8. Make sure the solution tank drainage cap (5) is closed. If it isn't, close it (

Fig.5

).

9.

Make sure the water system filter cap (6) is closed. If it isn't, close it (

Fig.6

).

4

4

6

5

5

6

10. Make sure the cap of the recovery tank drainage tube (7) is closed. If it isn't, close it (

Fig.7

).

11. Make sure the vacuum tube (8) is correctly connected to the sleeve in the squeegee body. If it

isn't, connect it (

Fig.8

).

12.

Make sure the vacuum motor filter (9) is correctly connected and is clean (

Fig.9

). If it isn't, clean

7

7

9

8

8

9

13.

Make sure the filter basin (10) is correctly connected and is clean (

Fig.10

). If it isn't, clean it (see

”).

14. Make sure the recovery tank cover is properly closed. If it isn't, close it.

10

10

STARTING WORK

To start working, proceed as follows:

1. Carry out all the checks listed in the chapter “

2. Connect the plug (1) of the power cable (2) to the mains supply socket (3) (

Fig.1

).

CAUTION:

We recommend handling the power cable with dry hands to avoid serious injury.

3.

Go to the driving position, behind the machine.

4. Switch on the machine by setting the main switch to “I”, press the button (4)

(Fig.2)

.

NB

:

if the LED in the button switch (4) is on it means that the switch is set to “I” (

Fig.2

). if the

LED in the button switch (4) is off it means that the switch is set to “0”.

5. Set the main key switch to “I”, turn the key (5) by a quarter turn to the left (

Fig.3

).

2

4

3

1

5

2

3

1

NB

: the steps for a complete scrubbing and drying cycle are explained below.

6. Lower the brush head body and detach the "BRUSH HEAD BODY CONTROL" pedal (6) at the

back of the machine (

Fig.4

).

7. Lower the squeegee body and turn the squeegee control lever (7) in the direction of the arrow

(

Fig.5

). The lever is located on the back of the machine.

8. When the dead man's lever (8) is pressed, the machine will begin to move. The lever is located

underneath the control handlebars (

Fig.6

).

5

7

4

6

8

7

NB

:

the gearmotor will only begin functioning, and the solenoid valve will only begin dispensing

detergent solution, when the brush head body is in its working position.

9.

During the first few metres, check that the detergent solution coming out is suitable for the task in

hand. If it isn't, adjust it after reading the section "

REGULATING THE DETERGENT SOLUTION

The machine will start to work at maximum efficiency until the detergent solution is finished.

During the first few metres, check that there is sufficient solution and that the squeegee is drying

correctly.

NB

:

If the dead man's lever is released during the scrubbing with drying operation, the brush

motor and the solenoid valve will be deactivated. The vacuum motor will continue working until

the squeegee control lever is rotated to bring it back to its idle position.

NB

:

if the squeegee body is raised during the scrubbing and drying operation, the vacuum

motor will continue working at maximum speed for a certain period of time, and then switch off.

This ensures that all the liquid in the vacuum tube is eliminated.

NB

:

when filling the solution tank, it is good practice to empty the recovery tank using the

special drainage tube.

SCRUBBING WITH DRYING

To perform a scrubbing and drying program, proceed as follows:

1. Carry out all the checks listed in the chapter “

”.

2. Connect the plug (1) of the power cable (2) to the mains supply socket (3) (

Fig.1

).

CAUTION:

We recommend handling the power cable with dry hands to avoid serious injury.

3. Go to the driving position, behind the machine.

4. Switch on the machine by setting the main switch to “I”, press the button (4)

(Fig.2)

.

NB

:

if the LED in the button switch (4) is on it means that the switch is set to “I” (

Fig.2

). if the

LED in the button switch (4) is off it means that the switch is set to “0”.

5. Set the main key switch to “I”, turn the key (5) by a quarter turn to the left (

Fig.3

).

2

4

1

2

3

1

3

5

6. Lower the brush head body and release the "BRUSH HEAD CONTROL" pedal (6) at the back of

the machine (

Fig.4

).

7. Lower the squeegee body and turn the squeegee control lever (7) in the direction of the arrow

(

Fig.5

). The lever is located on the back of the machine.

8. When the dead man's lever (8) is pressed, the machine will begin to move. The lever is located

underneath the control handlebars (

Fig.6

).

NB

:

the brush head body will only begin to descend to its working position when the dead

man's lever has been pressed.

NB

:

the gearmotor will only begin functioning, and the solenoid valve will only begin dispensing

detergent solution, when the brush head body is in its working position.

6

8

5

7

4

6

15