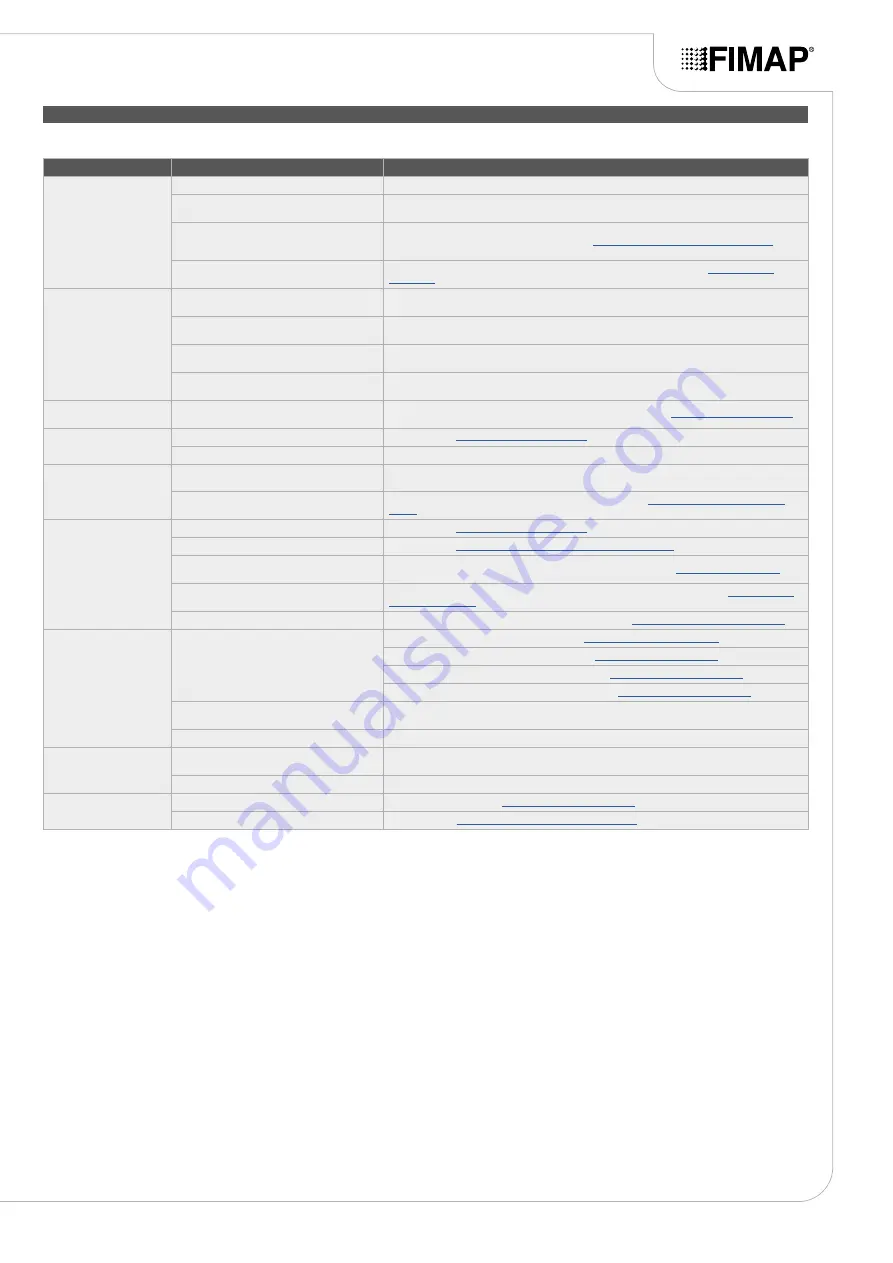

TROUBLESHOOTING

This chapter lists the most common problems linked with the use of the machine. If you are unable to resolve the problems with the information given here, please contact your nearest assistance centre.

21

PROBLEM

POSSIBLE CAUSE

SOLUTION

THE MACHINE DOES NOT

START

The main switch is set to “0”.

Make sure the main switch is on “I”. If it isn't, turn the key clockwise.

Check that, when switched on, there are no alarm

messages on the control display.

Stop the machine immediately and contact the technician of the specialised service centre, or press the SOS

button if the HFM kit is installed.

Make sure the batteries are correctly connected to

each other and that the battery connector is connected

to the electrical system connector.

Connect the batteries correctly inside the machine (see

INSERTING THE BATTERIES IN THE MACHINE

”).

Check the charge level of the batteries.

If the battery charge level is critical, perform a complete recharge cycle (see paragraph

CHARGING THE

BATTERIES

”).

THE BATTERIES ARE NOT

CHARGED CORRECTLY

(VERSIONS WITH BUILT-IN

BATTERY CHARGER)

The plug on the battery charger cable is not correctly

inserted in the socket on the battery charger itself.

Reconnect the battery charger power cable.

The plug on the battery charger power cable is not

correctly inserted in the electrical outlet.

Check that the battery charger power supply cable plug is connected to the mains socket.

The characteristics of the mains power supply do not

correspond to those required by the battery charger.

Check that the characteristics in the battery charger plate are the same as those of the mains supply.

The LEDs of the battery charger blink repeatedly.

Referring to the battery charger use and maintenance manual, check the meaning of the flashing signals that the

battery charger emits dung the battery recharge stage.

THE MACHINE HAS A VERY

LOW WORKING AUTONOMY

Check the battery charge level (check the symbol on

the control display).

If the battery charge level is critical, perform a complete recharge cycle (see "

”).

THE MACHINE DOES NOT

MOVE

The machine does not start.

”.

There is a drive pedal fault.

Contact your nearest service centre.

NOT ENOUGH DETERGENT

SOLUTION ON THE BRUSH

The quantity of detergent solution in the water system

is not sufficient for the work to be carried out.

Check that the amount of detergent solution present in the machine water system is sufficient for the work to be

carried out.

Detergent solution filter obstructed.

Check the detergent solution filter isn't obstructed. If it is, clean it (see “

OCLEANING THE WATER SYSTEM

FILTER

”).

THE MACHINE DOES NOT

CLEAN CORRECTLY

The machine does not start.

”.

Not enough detergent solution comes out.

NOT ENOUGH DETERGENT SOLUTION ON THE BRUSH

”.

The brushes have not been inserted correctly in the

machine.

Check that the disc brushes have been correctly inserted in the machine (see “

The type of brush used is not suitable for the dirt to

be removed.

Make sure the brushes fitted on the machine are suitable for the work to be carried out (see “

”.

The brush bristles are excessively worn.

Check the condition of the brush, and replace it if necessary (see “

REPLACING THE BRUSH HEAD BRUSH

”).

THE SQUEEGEE DOES NOT

DRY PERFECTLY

The vacuum unit is obstructed.

Make sure the squeegee is free of obstructions (see “

”).

Make sure the vacuum tube is free of obstructions (see “

Make sure the vacuum cap filter is free of obstructions (see “

”).

Make sure the vacuum motor filter is free of obstructions (see “

The cap on the recovery tank drainage tube is not

properly positioned.

Check that the cap on the recovery tank drainage tube is positioned properly.

The recovery tank lid is not positioned correctly.

Check that the recovery tank lid is properly positioned on the machine.

EXCESSIVE FOAM

PRODUCTION

The detergent being used is not suitable.

Check that a low foam detergent has been used. If necessary, add a small quantity of anti foam liquid to the

recovery tank.

The floor is not very dirty.

Dilute the detergent more.

THE MACHINE DOES NOT

VACUUM CORRECTLY

The recovery tank is full.

Empty the recovery tank (see “

”).

The vacuum device is obstructed

Read the section "