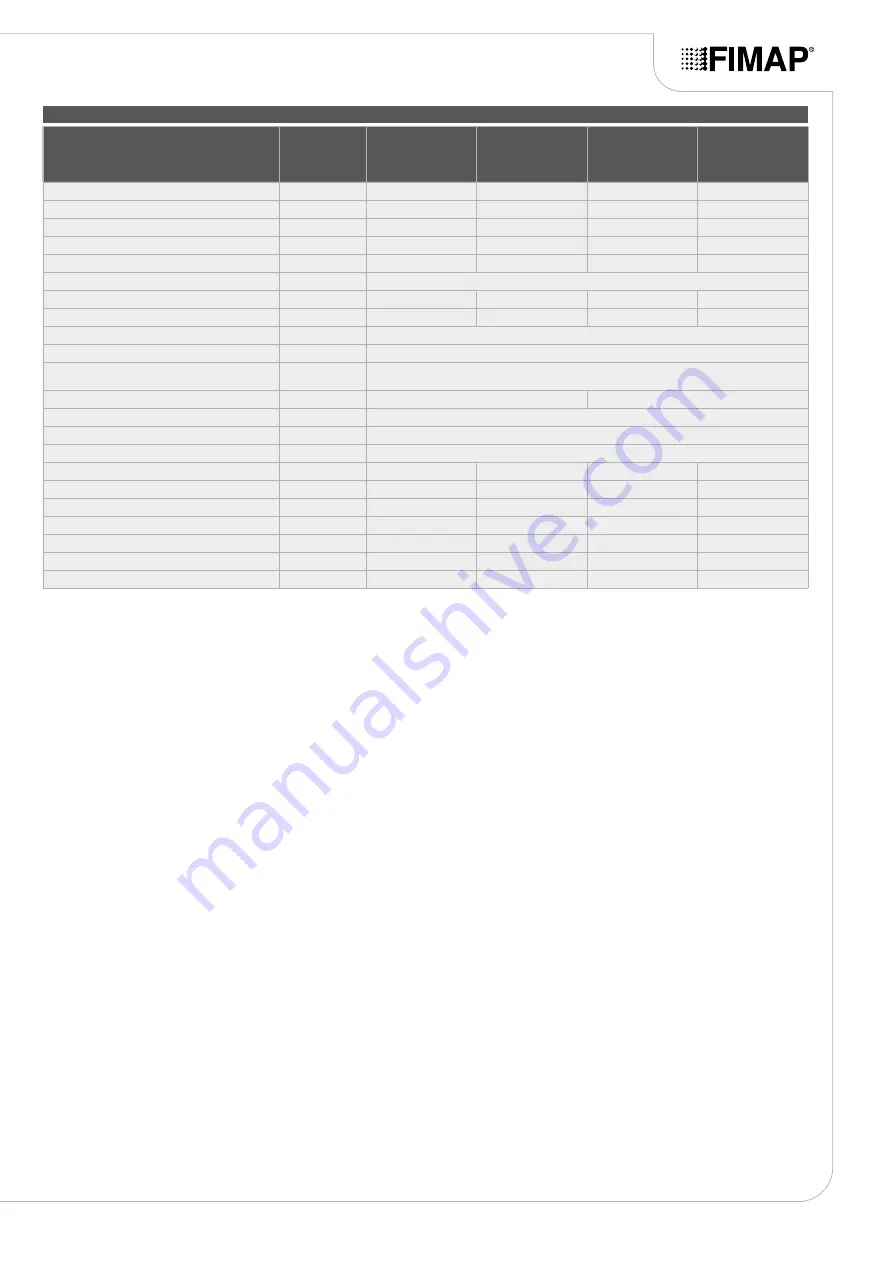

TECHNICAL DATA

Remarks:

(1) Machine weight: refers to the overall weight of the machine,with the batteries, with both tanks empty.

(2) Machine weight during work operations: refers to the overall weight of the machine, with the solution tank full, with the recovery tank empty.

11

TECHNICAL DATA

Unit of

measurement

symbol

MAXIMA 2017

BASE 50 E

230V

MAXIMA 2017

BASE 60 E

230V

MAXIMA 2017

BASE 50 E

110V

MAXIMA 2017

BASE 60 E

110V

Rated machine power

W

825

1200

825

1200

Working capacity up to

m

2

/h

1275

1513

1275

1513

Working width

mm

510

605

510

605

Squeegee width

mm

712

785

712

785

Brush head brush diameter (number - diameter)

mm

1 - 510

2 - 310

1 - 510

2 - 310

Number of brush head brush rotations

rpm

140

Brush head motor (voltage / nominal power)

V - W

230 - 375

230 - 375

110 - 375

110 - 375

Maximum weight exerted on the brush head

kg

21

27

21

27

Maximum possible gradient

%

2

Maximum ambient temperature for machine operation

°C

+40

Minimum ambient temperature for using the machine's

scrubbing functions

°C

+5

Vacuum motor (voltage - nominal power rating)

V - W

230 - 450

110 - 450

Vacuum on vacuum head

mbar

123

Maximum solution tank capacity

l

53

Maximum recovery tank capacity

l

55

Machine dimensions (length - width - height)

Mm

1299 - 558 - 1097

1268 - 641 - 1097

1299 - 558 - 1097

1268 - 641 - 1097

Machine weight during transport

(1)

Kg

100

110

100

110

Machine weight during work operations

(2)

Kg

154

164

154

164

Sound pressure level (ISO 11201) - L

pA

dB (A)

66,8

66,8

66,8

66,8

Uncertainty K

pA

dB (A)

1,5

1,5

1,5

1,5

Hand vibration level (ISO 5349)

m/s

2

<2,5

<2,5

<2,5

<2,5

Vibration measurement uncertainty

-

-

-

-