AT THE END OF THE WORK

At the end of the work, and before carrying out any type of maintenance, perform the following

operations:

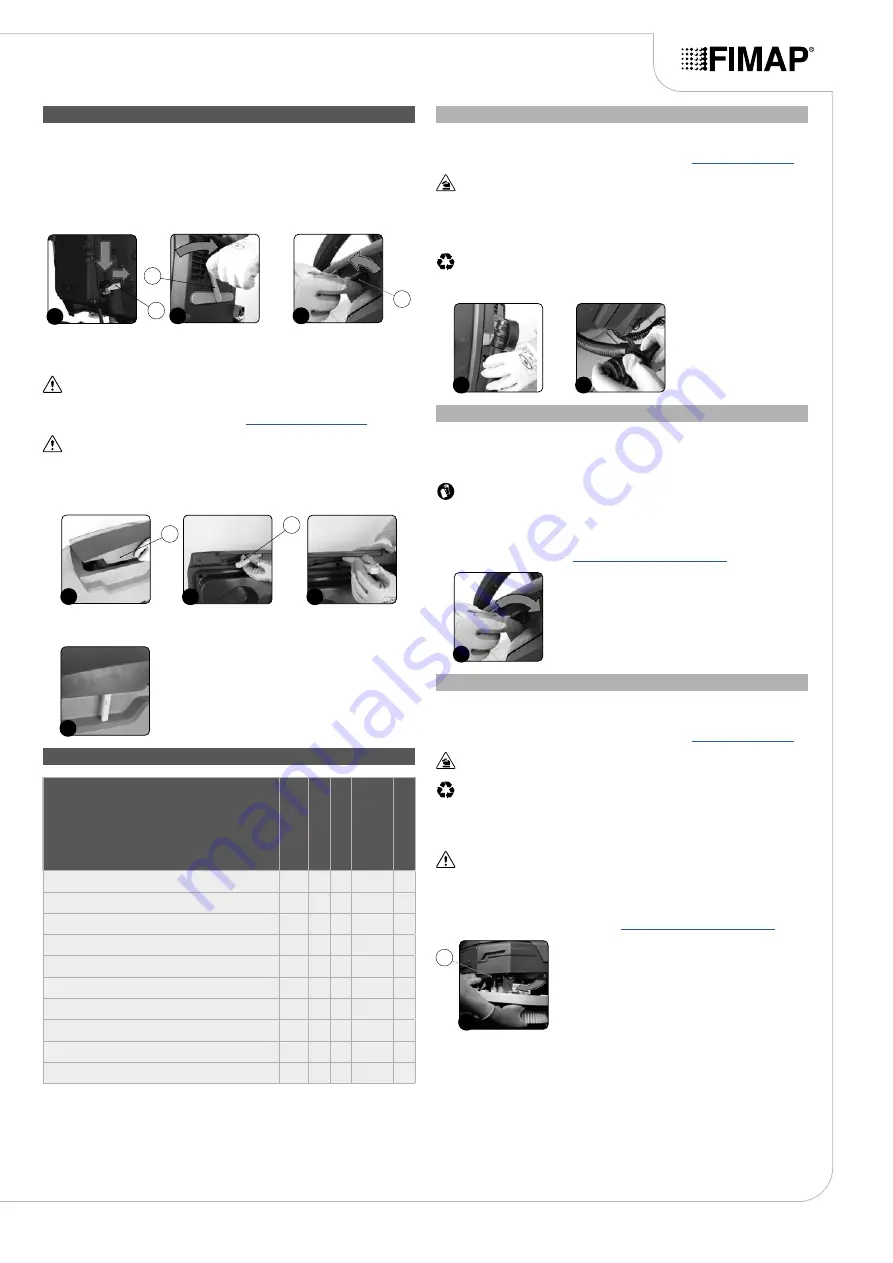

1. Raise the brush head body and detach the "BRUSH HEAD CONTROL" pedal (1) at the rear of

the machine from the plate retainer (

Fig.1

).

2.

Raise the squeegee body off the floor by means of the lever (2) on the back of the machine

(

Fig.2

).

3. Take the appliance to the dedicated dirty water drainage area.

4.

Switch off the machine by turning the main switch (3) to "0", making a quarter turn of the key in

the direction of the arrow (

Fig.3

). Remove the key from the instrument panel.

1

1

2

2

3

3

5. Carry out all the procedures listed in the paragraph “RECOMMENDED PERIODIC

MAINTENANCE” (in the column “AT THE END OF THE WORK”).

6. Take the appliance to the designated machine storage place.

ATTENTION

: park the machine in an enclosed place, on a flat surface, and at a safe distance

from any objects that could either damage it or be damaged due to contact with the machine

itself.

7. Make sure the machine is in a safe condition (see “

ATTENTION

: if the machine is left unused for more than one whole day, remove the brush

from the brush head body, and the squeegee body from the squeegee support.

8. Grip the handle (4) on the right-hand side of the recovery tank (

Fig.4

) and turn the tank as far as

it will go, until it reaches the maintenance position.

9. Grip the prop (5) and turn it as far as it will go (

Fig.5

), until it reaches the work position.

10. Block the rotation of the prop (5) by pushing it towards the inside of the cover (

Fig.6

).

5

5

6

4

4

11. Grip the handle (4) on the right-hand side of the recovery tank and turn the tank as far as it will go,

until it reaches the work position (

Fig.7

).

7

RECOMMENDED MAINTENANCE OPERATIONS

TYPE OF MAINTENANCE

AT THE END OF THE WORK

DAIL

Y

WEEKL

Y

BEFORE A

LONG

PERIOD OF NON- USE

TRANSPORT

DRAINING THE RECOVERY TANK

X

X

X

CLEANING THE SQUEEGEE BODY

X

X

X

CLEANING THE BRUSH HEAD BRUSH (VERSION 50E)

X

X

CLEANING THE BRUSH HEAD BRUSHES (60E VERSION)

X

X

CLEANING THE RECOVERY TANK

X

X

X

EMPTYING THE SOLUTION TANK

X

X

X

X

CLEANING THE WATER SYSTEM FILTER

X

X

CLEANING THE VACUUM TUBE

X

X

CLEANING THE SOLUTION TANK

X

X

CLEANING THE VACUUM WAND KIT

X

X

X

DRAINING THE RECOVERY TANK

Proceed as follows to empty the recovery tank:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

3. Release the recovery tank drainage tube (on the back of the machine) from the retainers (

Fig.1

).

4. Bend the end of the drainage tube in order to create a choke and prevent the content from coming

out (

Fig.2

), then position the tube on the discharge surface, unscrew the cap, and gradually

release the tube.

NB

: the place designated for this operation must comply with current environmental protection

regulations.

5. Repeat the operations in reverse order to reassemble all the parts.

2

1

CLEANING THE BRUSH HEAD BRUSH (VERSION 50E)

Careful cleaning of the brush guarantees better cleaning of the floor, as well as a longer brush head

gearmotor lifespan. To clean the brush, proceed as follows:

1. Take the machine to the maintenance area.

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

2. Turn the brush anti-clockwise until it comes out of the seat of the brush-holder plate (

Fig.1

).

3. Clean the brush under a stream of running water to remove any impurities from its bristles. Check

the wear status of the bristles and replace the brushes if they are excessively consumed (the bristle

protrusion must not be less than 10mm; this distance is indicated on the brush by the yellow band).

When replacing the brush, read "

REPLACING THE BRUSH HEAD BRUSH

".

1

CLEANING THE BRUSH HEAD BRUSHES (VERSIONS 60E)

Careful cleaning of the brush guarantees better cleaning of the floor, as well as a longer brush head

gearmotor lifespan. To clean the brush, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious

injury to hands.

N.B.

: the place designated for this operation must comply with current environmental

protection regulations.

3. Go to the front of the machine.

4. Press the brush-holder plate retainer (1) and simultaneously rotate the brush in the direction

shown in the image (

Fig.1

).

ATTENTION

:

Fig.1

shows the rotation direction of the left-hand brush.

5. When brush rotation is prevented, turn until the button on the brush is disengaged from the

coupling spring on the brush-holder plate.

6. Repeat the same operation for the right-hand brush.

7. Clean the brush under running water to remove any impurities from its bristles. Check the bristles

are not worn; in the event of excessive wear, replace the brush (the bristles should be at least

10mm long). When replacing the brush, read "

REPLACING THE BRUSH HEAD BRUSH

".

1

1

17