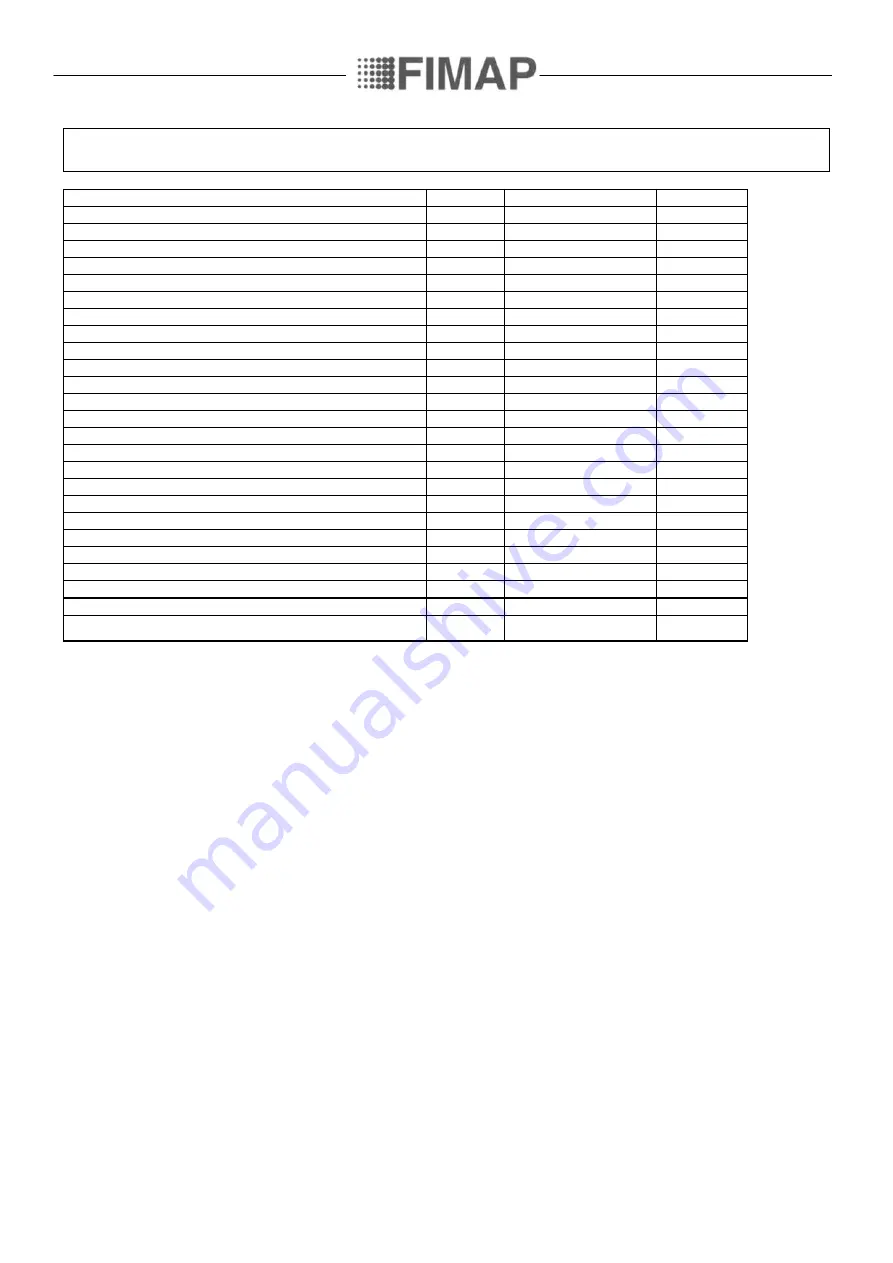

TECHNICAL DESCRIPTION

Minny 17

TECHNICAL DESCRIPTION

U/M

Minny 20

Working width

mm

430

-

Squeegee length

mm

560

-

Working capacity, up to

m

2

/h 1500 -

Brush diameter

mm

430

-

Brush rpm

rev/min.

140

-

Brush pressure

kg

25

-

Brush motor, supply voltage

V

24

-

Brush motor, rated power

W

400

-

Type of drive

Semi-aut.

-

Max gradient

2%

-

Suction motor, supply voltage

V

24

-

Suction motor, rated power

W

410

-

Suction vacuum

mbar

120

-

Solution tank

l

26

-

Recovery tank

l

26

-

Machine length (when working)

mm

1000

-

Machine length (when transported)

mm

1120

-

Machine height

mm

1005

-

Machine width (without squeegee) mm

470

-

Batteries V/Ah

24/70

-

Battery weight

kg

52

-

Battery compartment

mm

175x335x255 (2x)

-

Machine weight (empty without batteries)

kg

65

-

Sound pressure level (in compliance with IEC 704/1)

dB (A)

70

-

Vibration level

m/s

2

1,93 -

4