PREPARATION OF THE APPLIANCE

1.

HANDLING THE PACKED APPLIANCE

The device is delivered in dedicated packaging. The packaging elements (plastic bags, clips, etc.) are potentially hazardous, and, therefore, must not

be left within the reach of children, incapacitated persons, etc. The device is housed in dedicated packaging fitted with a pallet to facilitate fork-lift

handling. The packages cannot be placed on top of each other.

Gross weight of device, including packaging, is:

MMx 43-50-52 B: 100 kg (weight of unladen

device including packaging)

MMx 43-50-52 BT: 120 kg (weight of unladen

device including packaging)

The dimensions of the package are as follows:

MMx

A: 665 mm

B: 1230 mm

C: 1145 mm

WARNING: It is recommended that all the packaging components be kept in case the appliance ever needs transporting.

WARNING: Move the packaged product with handling equipment that complies with legal requirements regarding size and mass of

the packaging.

2.

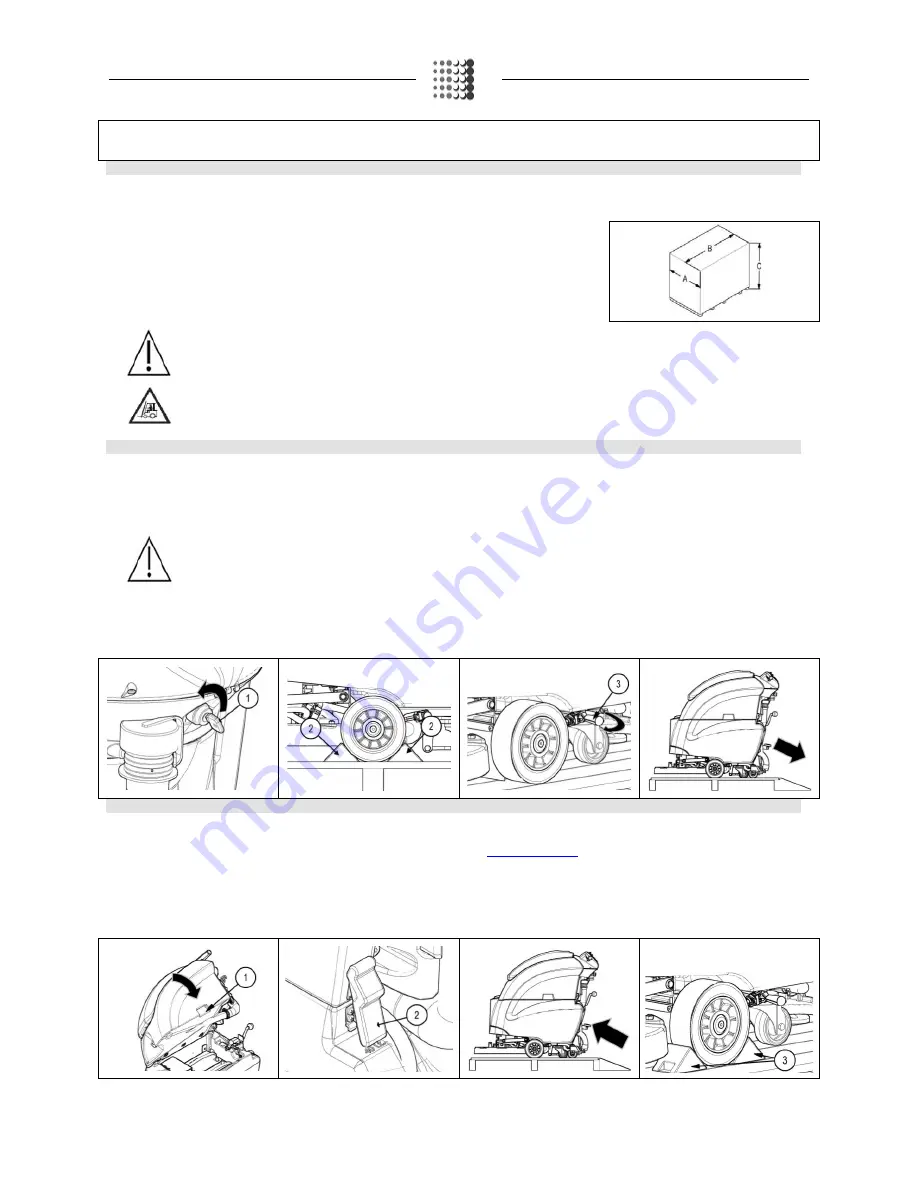

HOW TO UNPACK THE MACHINE

The procedure for removing the device from its packaging is the following:

1.

Remove the outer package.

2.

Check that the main switch (1) is in the “0” position. If this is not the case, turn the key by a quarter of a turn to the left.

3.

Remove the key from the instrument panel.

4.

The device is secured to the pallet with wedges (2) that lock the wheels. Remove the wedges.

ATTENTION: During this operation, check there are no people or objects near the device.

WARNING: You are advised to always wear protective gloves, to avoid the risk of serious injury to your hands.

5.

For BT versions, take off the parking break by rotating the lever (3) in the sense shown by the picture.

6.

Using a chute, bring the machine down from the pallet. Do not assemble the brushes and the rear squeegee before unloading the device, and

avoid violently jolting the brush head unit and the squeegee support.

7.

Keep the pallet and all packaging components for any future transport needs.

3.

HOW TO TRANSPORT THE APPLIANCE

The procedure for the safe handling of the device is the following:

1.

Using a chute, slide the machine onto the pallet.

2.

Take all necessary steps to ensure that the device is in a safe condition (see “

MACHINE SAFETY

”).

3.

Grip the handle (1) on the rear left side of the recovery tank and turn the recovery tank until it reaches the work position.

4.

Secure the recovery tank with the hinge (2).

5.

Carry out this operation with the rear squeegee and the brushes detached from the machine.

6.

Secure the device to the pellet using wedges (3).

Page 9