Page 3

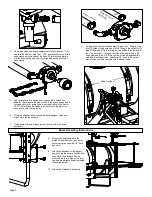

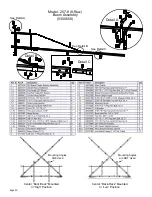

11. Loosen the eye bolts and remove the 7” hinge bolts. Line up the

outer booms and reassemble the hinge bolt through the outer

boom yoke, the hinge casting and the spring connector. Tighten

the eye bolt until the spring is at the desired tension. Lock the

eye bolt in place with the inner whiz flange locknut.

12. Bolt on the boom extensions using the 3/8” x 1-3/4” bolts and

hex lock nuts.

Loosen nut on eye bolt

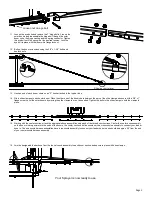

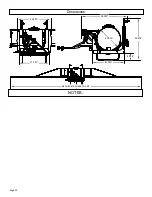

13. Hook an end of each boom chain on an “S” hook attached to the top bar tube.

14. Slip a slide clamp onto each outer boom. Place the other end of the boom chain between the ears of the slide clamp and secure with a 3/8” x 1”

flange screw. Level the outer booms by moving the slide clamps in or out as needed. Tighten the bolts in the slide clamps to hold the clamps in

place.

Slide in or out to level

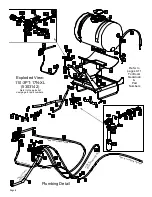

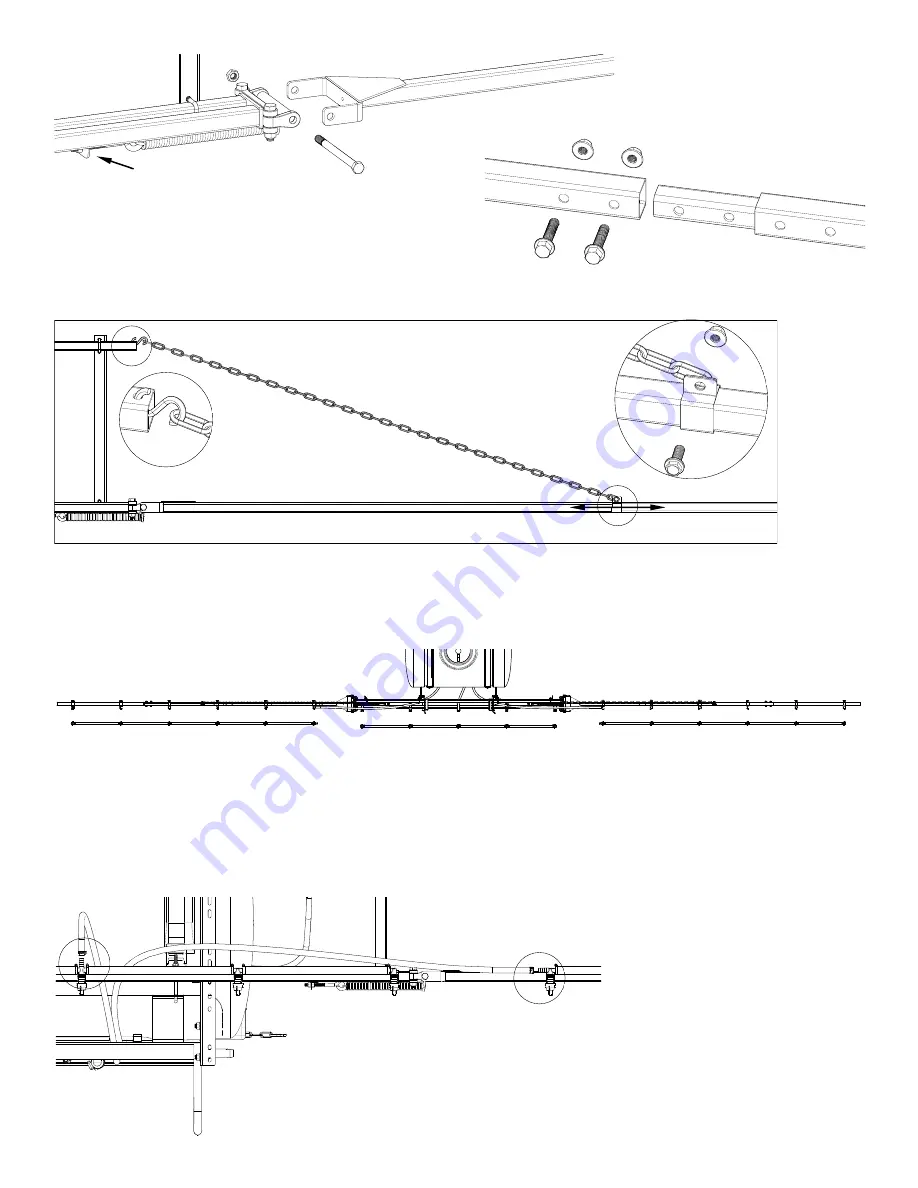

15. Starting with the center section, attach the appropriate hose assemblies onto each of the three boom sections. Center the center hose assembly

on the boom, working outward to the ends of the booms. the center section has five nozzles with a cross nozzle assembly to connect your feeder

hose to. The end nozzle harness assemblies have a tee nozzle assembly to connect your feeder hose to and should be approx. 20” from the end

of your center nozzle harness assembly.

16. Join the designated feeder hose from the tee valve sub-assembly to each boom section and secure in place with hose clamps.

Your Sprayer is now ready to use.

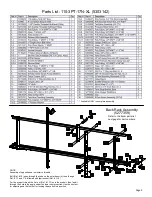

Summary of Contents for 110-3PT-17N-XL

Page 13: ...Page 13 NOTES ...