Page 2

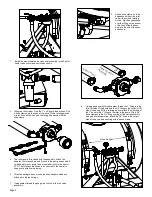

1.

Install the preassembled tee valve sub-assembly to the 3-point

carrier valve mount and position as shown.

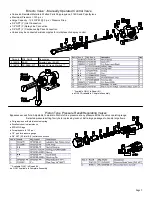

2.

Slide a hose clamp on to the

bypass hose (from the relief

valve), then with a twisting

motion, slip the bypass hose

over the fitting on the bottom

of the tank. Slide the hose

clamp to the end of the hose

and secure.

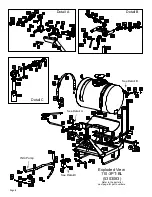

3.

fitting into the strainer. Find the 1” x 36” pump feeder hose. Slip

a hose clamp onto the ends of the hose. With a twisting motion,

slip the hose all the way onto the fitting and secure with the

hose clamp.

4.

Using a good quality thread sealant, thread the 1” fitting into the

inlet (IN) side of the pump and the 3/4” fitting to the outlet (OUT)

side of the pump. With a twisting motion, attach the other end of

the 1” hose to the 1” fitting on the inlet to the pump. Slip a 3/4”

hose clamp onto the 3/4” hose coming off the valve assembly

and with a twisting motion, attach the 3/4” hose to the output

side of the pump and securing with the hose clamp.

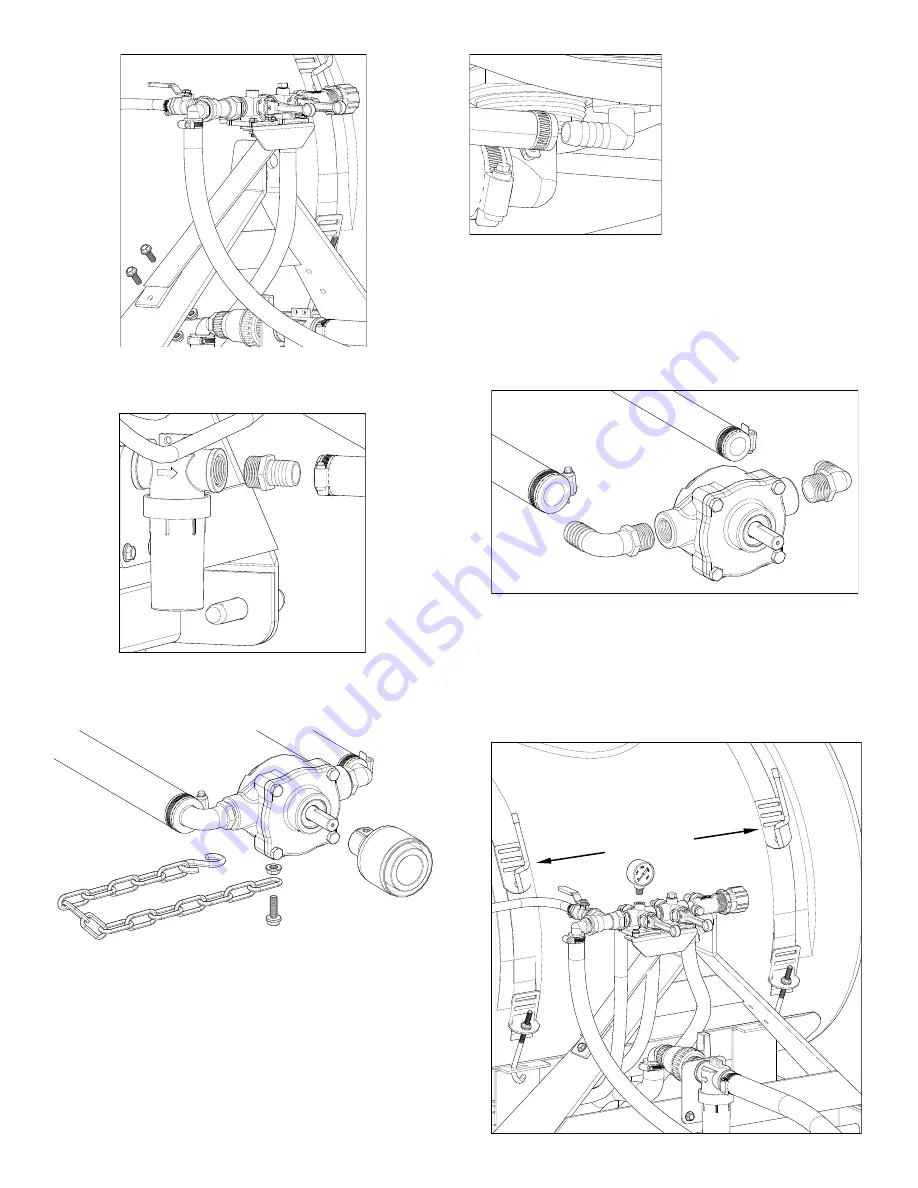

5.

The roller pump IS included with the assembly. Attach the

adapter, the torque chain and S-hook to the pump as needed. It

is intended for your pump to be mounted directly to the tractor

PTO. The torque chain needs to be secured to the tractor to

keep your pump from spinning.

6.

Wrap the handgun hose around the hose hangers which are

attached to the tank straps.

7.

Using sealant thread the gauge into the top of the tee valve

assembly.

Inle

t to

Pum

p

Ou

tlet t

o Va

lve

Asse

mbly

1”

3/4”

Hose Hangers