Page 4

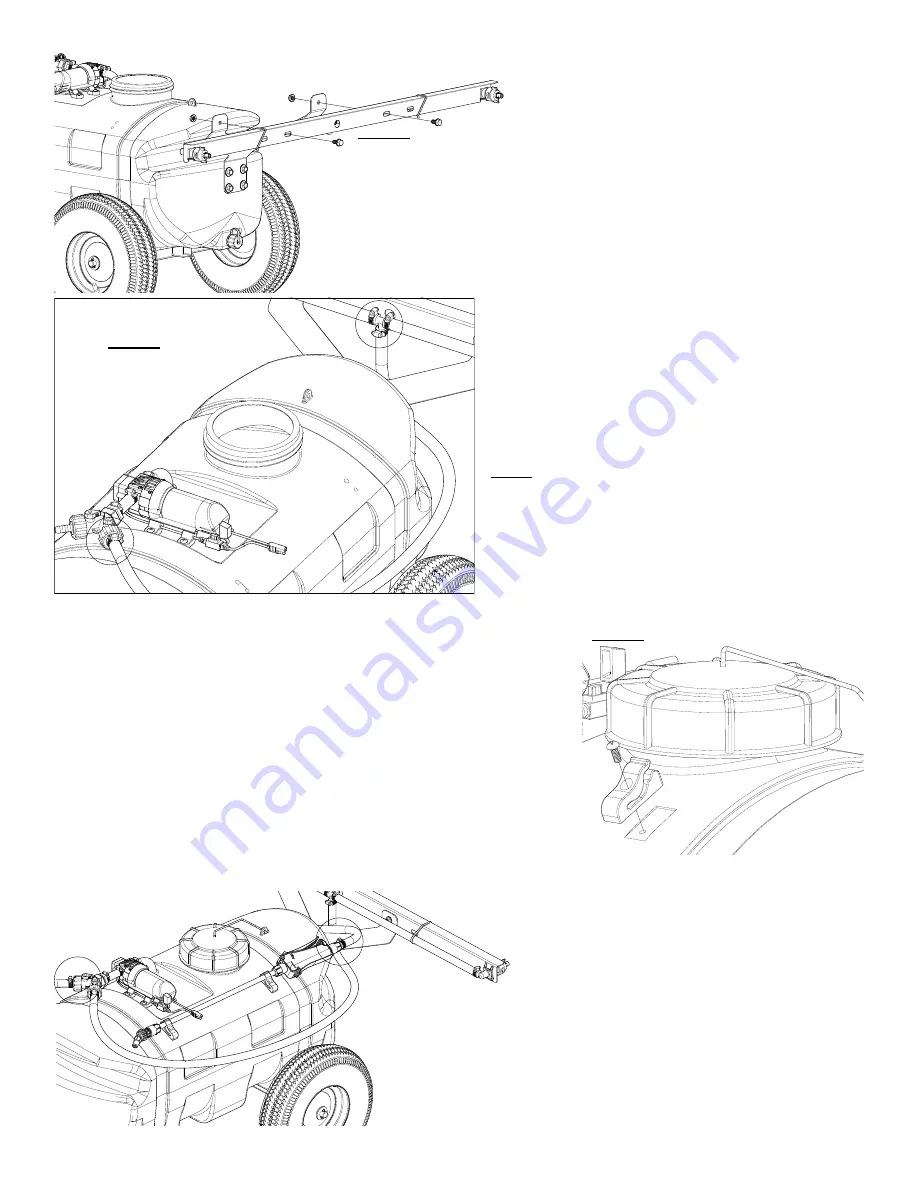

Assembly Procedure (15-2N-TRL-GS)

After your trailer boom mount is secured to the tank.

1/2” socket wrench & wrench is required for this step.

Attach the boom assembly to the trailer boom mount.

Secure in place with (2) flanged hex bolts and (2) flanged

hex nuts.

After your boom is attached to the trailer boom mount, locate

the feeder hose and the (2) hose clamps from the parts bag.

Place the hose clamps loosely over each end of the feeder

hose. Slip the ends of the hose over the hose barbs on both

the y-valve manifold and the barb fitting on the nozzle har-

ness of the boom. Use a twisting motion, if necessary, to get

the hose fully onto each barb. Bring the hose clamps to the

connection point and tighten securely.

NOTE:

Make sure the boom feeder hose does not end up on the

‘outside’ of the spray wand hose, otherwise unwrapping the

spray wand hose from around the tank may be difficult.

*** The Sprayer should now be ready for use ***

Screw the lid onto the tank, if not already done.

Locate the (2) clips and (2) phillips head machine

screws from the parts bag.

A phillips head screwdriver is required for this step

Place a screw through the hole in the clip and bring it up to the tank,

where the embossments for the clips are (located on the rear side of the

tank)

Secure the clip/screw to the tank. Tighten so that the clip is secure. Do

this for each clip.

** DO NOT OVER-TIGHTEN **

The spray wand will snap into the clips once installed. Do not use exces-

sive force when placing the spray wand into the clips, as this could

cause the clips to break.

Place a hose clamp loosely over each end of handgun

hose. Slip the ends of the hose over the hose barb on

the y-valve manifold and the back of the spray wand.

Use a twisting motion, if necessary, to get the hose

fully onto each. Bring the hose clamps to the connec-

tion point and tighten securely.

Step 5

Step 6

Step 7