Page 2

Information About the Sprayer

Roller pumps are positive displacement pumps, which means that

the entire solution being pumped must go somewhere or the pump

will break. In this roller pumping system, solution is drawn from the

tank and forced to a planned source, such as boom nozzles or hand-

gun. The pressure is controlled by a pressure relief valve, which is a

spring-loaded device that controls the amount of fluid bypassed

(recirculated) to the tank. The gray handle is to be tightened to in-

crease pressure and loosened to decrease pressure.

The ‘directo-valve’ is the on/off control which allows the operator to

manually control the solution going to the boom.

IMPORTANT:

Remove tank lid and be sure the tank is

clean and free of any foreign material. Rinse tank out of any

tank residue before filling with water to test.

Tip Information

Important note about tips:

When you refer to the rate charts found

in this owners manual, these rates are based on water. Please read

this tip selection section carefully before attempting to operate your

boom assembly.

The selection of proper tips for the boom is determined by the gallon

per acre (GPA) requirement which is specified on the chemical label.

The following characteristics also have a determining factor and must

be considered.

1.

Speed of spraying (MPH).

2.

Boom nozzle spacing (specified in inches).

3.

Solution weight and conversion factor (CF)

4.

Gallons of solution to be sprayed per acre.

5.

Spraying pressure.

Useful Formulas:

GPM = Gallons Per Minute

GPA = Gallons Per Acre

MPH = Miles Per Hour

Calibration

Chemical labels may show application rates in gallons per acre, gal-

lons per 1000 square feet or gallons per 100 square feet. You will

note that the tip chart (later in this manual) shows 2 of these rating

systems. Once you know how much you are going to spray, then

determine (from the tip chart) the spraying pressure (PSI), and the

spraying speed (MPH).

Determining the proper speed of the pulling vehicle can be done by

marking off 100, 200 & 300 feet. The speed chart indicates the num-

ber of seconds it takes to travel the distances. Set the throttle and

with a running start, travel the distances. Adjust the throttle until you

travel the distances in the number of seconds indicated by the speed

chart. Once you have reached the throttle setting needed, mark the

throttle location so you can stop and go again, returning to the same

speed.

Add water and proper amount of chemical to the tank and drive to the

starting place for spraying

Using the Boom Nozzles

Four things must be considered before spraying with the boom.

How much chemical must be mixed in the tank.

Rate of spray (gallons per acre to be sprayed).

What pressure (p.s.i.) will be used.

Speed traveled (mph) while spraying.

Refer to the chemical label to determine your chemical mixture

See the tip chart to determine the pressure to be used. The

chart will also show the speed used when spraying.

Start the pump and open the valve to the boom nozzles.

Check the spray pattern. Usually you can see the coverage

better on a solid concrete surface, such as a driveway.

Spraying Solutions Other Than Water

Since all the tabulations are based on spraying water, which weighs

8.34 lbs. per USA gallon, conversion factors must be used when

spraying solutions which are heavier or lighter than water. To deter-

mine the proper size nozzle for the solution to be sprayed, first multi-

ply the desired GPM or GPA of solution by the rate conversion factor.

Then use the new converted GPM or GPA rate to select the proper

size nozzle.

Example:

Desired application rate is 20 GPA of 28% Nitrogen.

Determine the correct nozzle size as follows:

GPA (Solution) x Conversion Factor = GPA

20 GPA (28%) x 1.13 + 22.6 GPA (Water)

The applicator should choose a nozzle size that will supply 22.6 GPA

of water at the desired pressure.

Miscellaneous Conversion Factors

One Acre = 43,560 square feet = 0.405 Hectare

One Hectare = 2.471 Acres

One Gallon Per Acre = 9.35 Liters Per Hectare

One Mile = 5,280 Feet = 1,610 Meters = 1.61 Kilometers

One Gallon = 128 Fluid Ounces = 8 Pints = 4 Quarts = 3.79 Liters =

0.83 Imperial Gallons

One Pound Per Square Inch = 0.069 bar. = 6.895 Kilopascals

One Mile Per Hour = 1.609 Kilometers Per Hour

Higher pressure not only increases the flow rate of the nozzle, but it

also influences the droplet size and the rate of orifice wear. As pres-

sure is increased, the droplet size decreases and the rate of orifice

wear is increased.

The values given in the tabulation section of this owners manual

indicate the most commonly used pressure ranges for the associated

spray tips.

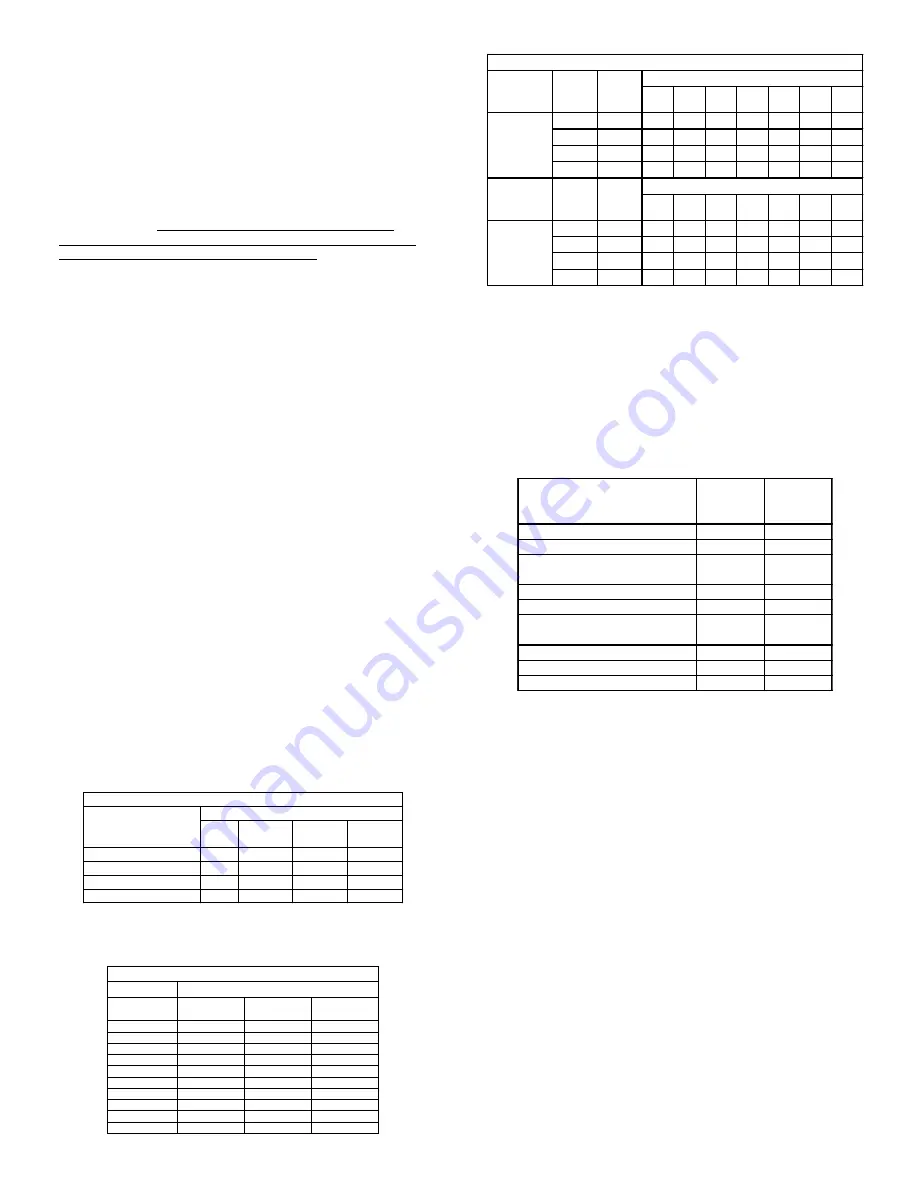

Speed in M.P.H.

(Miles Per Hour)

100 Ft.

200 Ft.

300 Ft.

1.0

68 sec.

136

205

2.0

34

68

102

3.0

23

45

68

4.0

17

34

51

5.0

14

27

41

6.0

11

23

34

7.0

9.7

19

29

8.0

8.5

17

26

9.0

7.6

15

23

10.0

6.8

14

20

Speed Chart

Time Required in seconds to travel a distance of

Weight of Solution

Specific

Gravity

Conversion

Factors

7.0 lbs. per gallon

.84

.92

8.0 lbs. per gallon

.96

.98

8.345 lbs. per gallon

(Water)

1.00

1.00

9.0 lbs. per gallon

1.08

1.04

10.0 lbs. per gallon

1.20

1.10

10.66 lbs. per gallon

(28% Nitrogen)

1.28

1.13

11.0 lbs. per gallon

1.32

1.15

12.0 lbs. per gallon

1.44

1.20

14.0 lbs. per gallon

1.68

1.30

Spray

Angle

20"

Spacing

30"

Spacing

40"

Spacing

TeeJet (Flat Spray)

65°

22"-24"

33"-35"

NR*

TeeJet (XR TeeJet)

80°

17"-19"

26"-28"

NR*

TeeJet (XR TeeJet)

110°

12"-14"

16"-18"

NR*

FloodJet

120°

***

***

***

* Not Recommended

*** Wide Angle Spray Tip is influenced by nozzle orientation.

The critical factor is to achieve a double spray patter overlap.

Suggested Minimum Spray Heights

Nozzle Type

Nozzle Height

1

MPH

2

MPH

3

MPH

4

MPH

5

MPH

6

MPH

8

MPH

15

.18

53.6

26.8

17.8

13.4

10.7

8.9

6.7

20

.21

62.4

31.2

20.8

15.6

12.5

10.4

7.8

30

.26

77.2

38.6

25.8

19.3

15.4

12.9

9.7

40

.30

88.0

44.0

29.8

22.0

17.8

14.9

11.1

1

MPH

2

MPH

3

MPH

4

MPH

5

MPH

6

MPH

8

MPH

15

.18

.61

.41

.31

.24

20

.21

.71

.48

.36

.29

30

.26

.88

.59

.44

.35

40

.30

1.0

.68

.51

.41

AIXR11003VP

Spray Tip Rate Chart (20" Spacing)

Tip

No.

Pressure

(psi)

Capacity

(GPM)

Gal. Per Acre - Based on Water

Tip

No.

Pressure

(psi)

Capacity

(GPM)

Gal. Per 1000 Sq. Ft. - Based on Water

AIXR11003VP