Reviews:

No comments

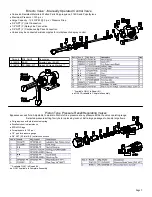

Related manuals for 200-3PT-BL

LMS-E6-45

Brand: paasche Pages: 4

BPG7000

Brand: BorMann Pages: 6

VIPU12

Brand: Vito Agro Pages: 8

175GD001

Brand: Smithco Pages: 112

CP19

Brand: Decoproyec Pages: 8

RC8101

Brand: RODCRAFT Pages: 18

ATTILA CDA

Brand: RB Spray Tech Pages: 11

SG-100

Brand: Praxair Pages: 69

53633

Brand: Workzone Pages: 30

0114-013514

Brand: Binks Pages: 14

Paint Crew HIGH PERFORMANCE AIRLESS SPRAYER

Brand: WAGNER Pages: 44

PS 3.20

Brand: WAGNER Pages: 88

MS4171

Brand: Hawthorne Pages: 56

IND-MD-DF-ESF-R2

Brand: Larson Electronics Pages: 2

352096 2007

Brand: Parkside Pages: 73

PS240C

Brand: Campbell Hausfeld Pages: 24

VS 20 OH

Brand: Lauda Pages: 20

Herbidome 350

Brand: Micron Pages: 24