Page 2

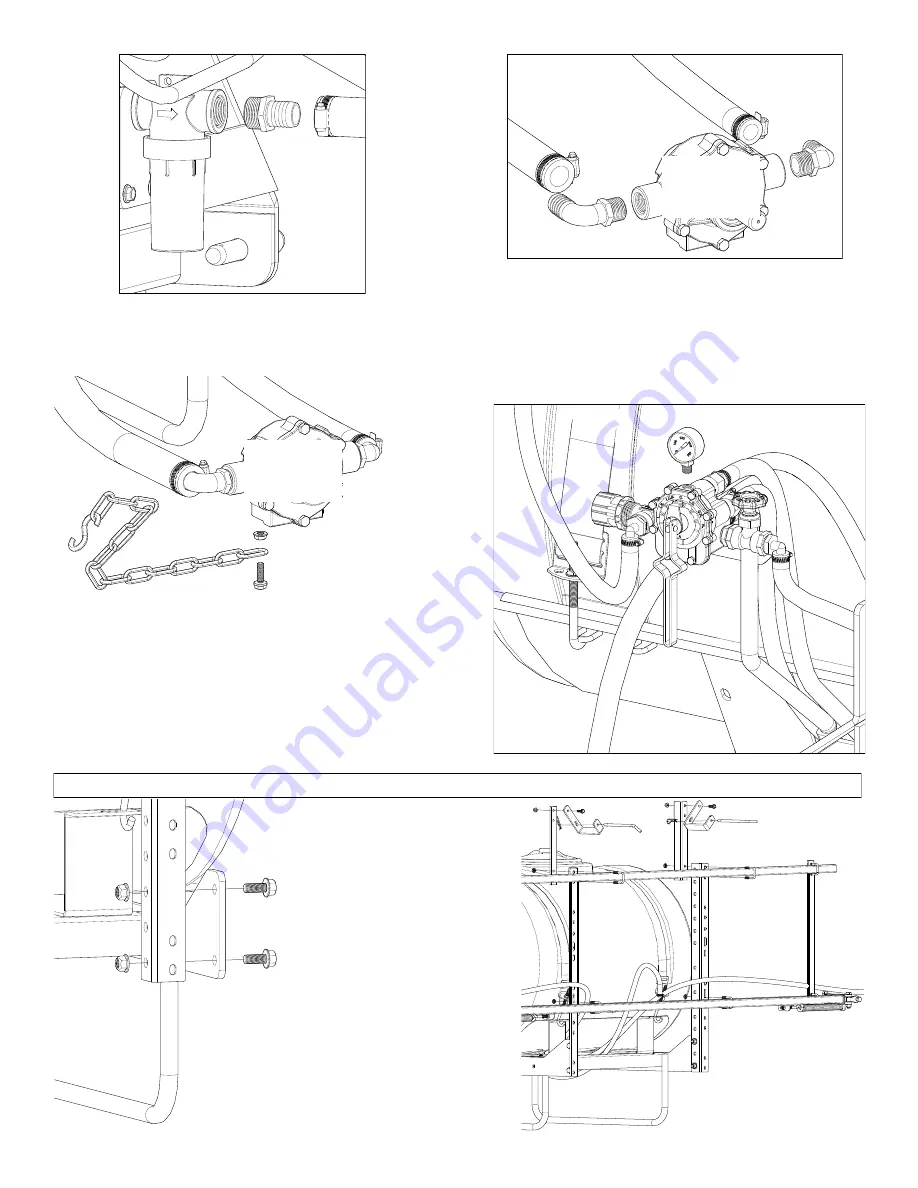

3.

Using a good quality thread sealant, carefully thread the 1” fit-

ting into the strainer. Find the 1” x 36” pump feeder hose. Slip a

hose clamp onto the ends of the hose. With a twisting motion,

slip the hose all the way onto the fitting and secure with the

hose clamp.

4.

Using a good quality thread sealant, thread the 1” fitting into the

inlet (IN) side of the pump and the 3/4” fitting to the outlet (OUT)

side of your pump. With a twisting motion, attach the other end

of the 1” hose to the 1” fitting on the inlet to the pump. Slip a

3/4” hose clamp onto the 3/4” hose coming off the valve assem-

bly and with a twisting motion, attach the 3/4” hose to the output

side of the pump and securing with the hose clamp.

5.

The roller pump is NOT included with the assembly. Attach the

adapter, the torque chain and S-hook to the pump as needed. It

is intended for your pump to be mounted directly to the tractor

PTO. The torque chain needs to be secured to the tractor to

keep your pump from spinning.

6.

Using sealant thread the gauge into the top of the tee valve

assembly.

7.

Mount the upright angles to the

inside of the mounts on the 3-point

carrier using the supplied 1/2” bolts

and nuts.

8.

Attach the backrack to the upright

angles using the square U-bolts and

nuts. Note: the backrack can be

mounted in either a high or low posi-

tion and the uprights can be adjusted

for desired height.

9.

Attach the U-brackets as shown.

Boom Assembly Instructions

Inle

t to

Pu

mp

Ou

tlet t

o Va

lve

As

sem

bly

1”

3/4”

Your

Pump

Your

Pump