Page 3

Assembly Procedure (LG-1500-303)

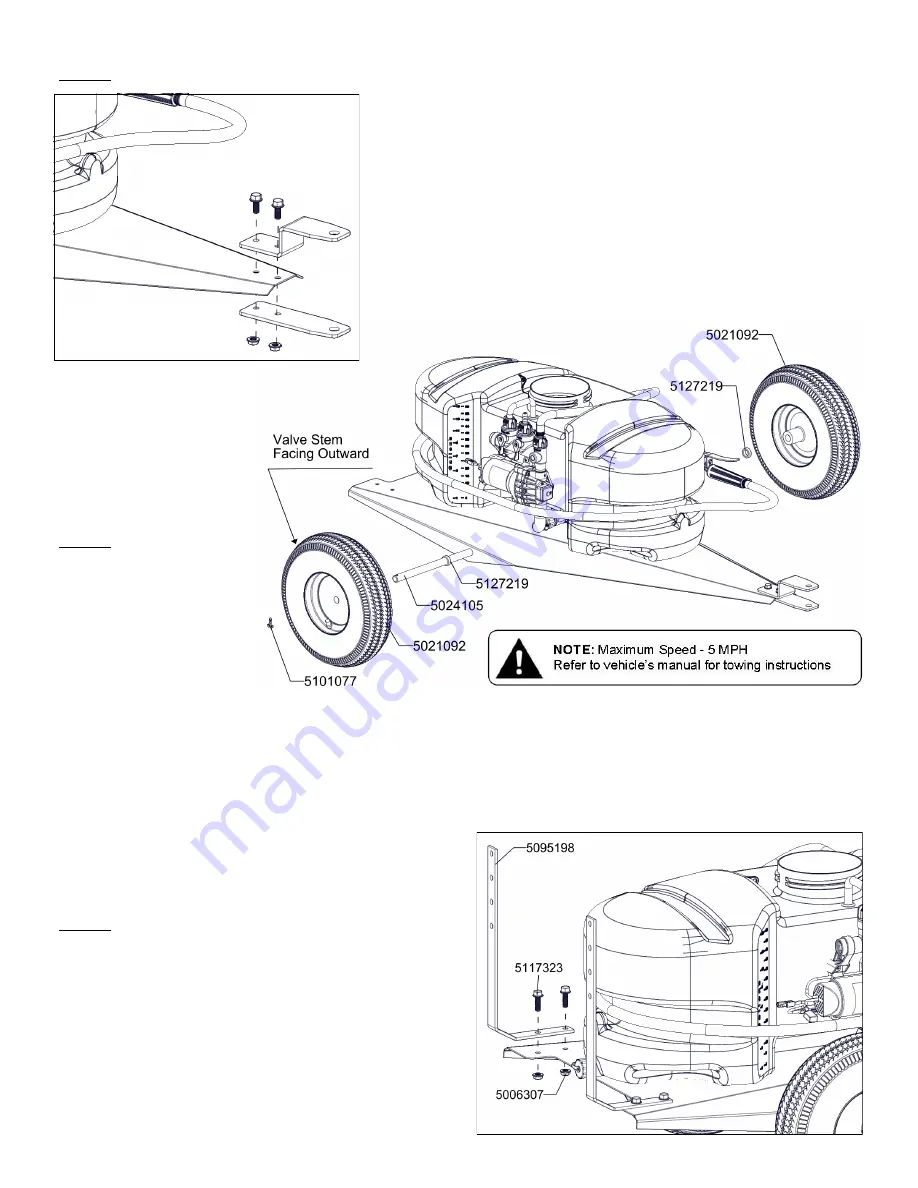

Step 1

Remove the hitch brackets, both flat and formed from the parts bag. The flat

one is to be placed under the frame and the formed one gets placed on top of

the frame.

Bolt them together, ‘sandwiching’ the frame between both of the brackets.

Using a 1/2” socket or wrench, tighten the 1” long bolts securely.

Use the 5/16” whiz nuts with the bolts.

They should grab tightly against the frame as you tighten the bolts down.

Remove the axle and (2) wheels from the carton. Remove the (2) wheel spacers and (2) cotter pins from the parts bag. Slide the

axle through the hole in one side of the frame and through the corresponding hole on the other side of the frame. You may need to

maneuver (squeeze) the frame slightly while doing this to get the axle through both holes. Center the axle about the frame as best

as possible. Slide a wheel spacer onto the axle. Now slide a wheel over the axle and up against the wheel spacer. Make sure the

valve stems of the wheels are facing outward. Place a cotter pin through the hole at the end of the axle. Using a needle nose pliers

or similar tool, bend the pins so that they will not slip out and the wheel will be retained on the axle. Repeat procedure for the oth-

er side.

**With another person helping by holding axle in place (if needed),

slightly push on tire until the hole in the axle clears the wheel and

place cotter pin in the hole to retain wheel.

Locate the (2) boom mounting brackets. These two brackets

mount to the rear of the frame with (2) bolts and (2) whiz nuts.

(Each Bracket)

Using a 1/2” socket or wrench, tighten the hardware securely.

The whiz nuts will grab tightly against the frame as you tighten

the bolts down.

Step 3

Step 2