Page 4

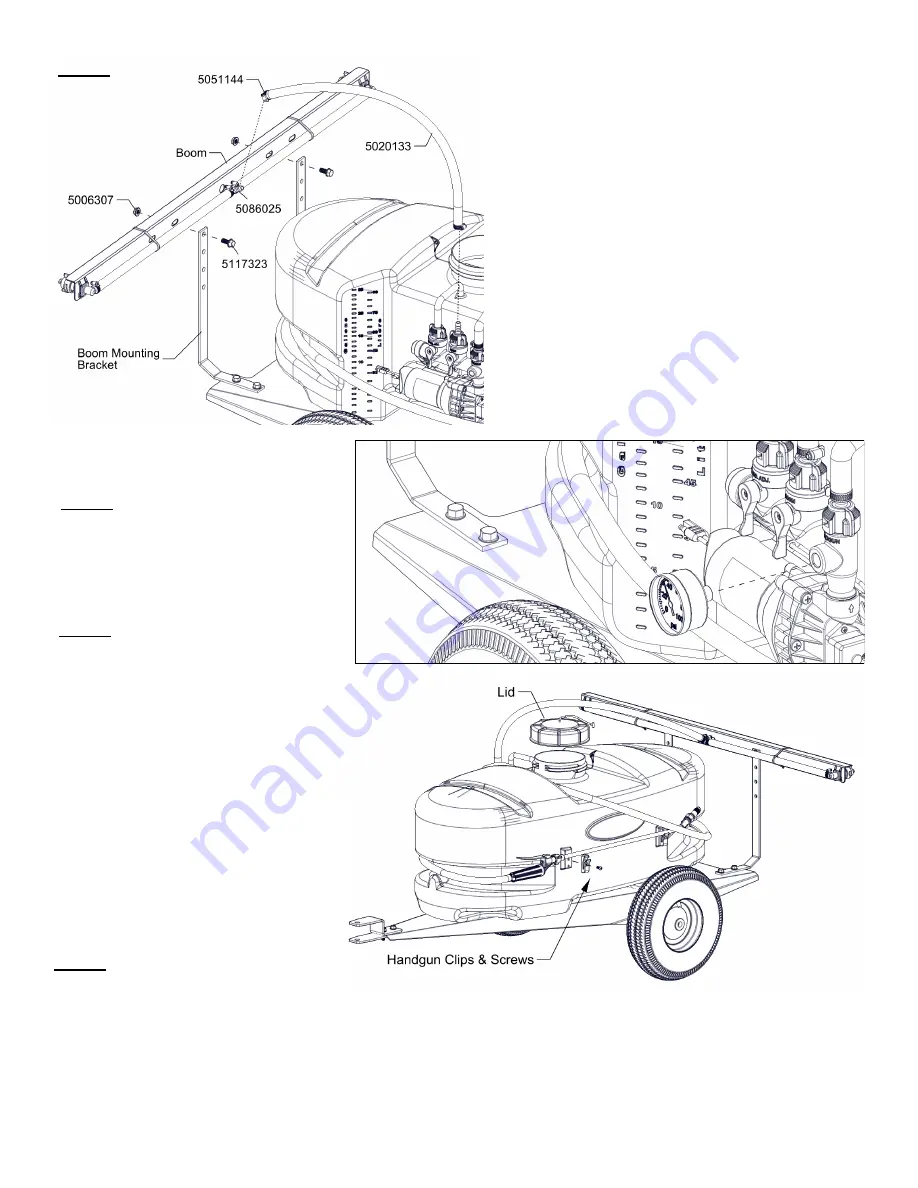

Step 4

Remove the 2-nozzle boom assembly from the

carton. Using (2) bolts and (2) whiz nuts, bolt the

boom to the upright boom mounting brackets.

There are four holes in the boom brackets, so

you can choose the most optimal (height) posi-

tion for your spraying purposes.

Tighten the hardware down, using a 1/2” socket

or wrench.

Find the 3/8” hose (30” long) and place hose

clamps loosely onto each end of the hose. Con-

nect this hose to the ‘TEE’ fitting on the boom

and to the ‘Boom’ line on the manifold. Tighten

the hose clamps snugly.

The boom is now installed.

Step 5

The tank lid has an 8” lanyard attached to it.

Slide the lanyard through the hole in the tab

at the top of the tank. This is so the lid can

‘hang’ or be retained onto the tank while

you are filling or rinsing the tank out. This

should help prevent loss or

damage of the lid.

Screw the lid onto the tank. Hand-tight

should be sufficient.

Screw the pressure gauge into the

manifold. Hand tight should be

sufficient.

Step 6

Step 7

Remove the (2) handgun clips and (2)screws from the parts bag. Use a phillips head screwdriver to screw them onto

the tank. Do not over tighten. These clips are where the spray wand is secured to the tank, while not in use.

NOTE:

The spray wand should already be attached to the 15 foot hose prior to assembly.

*** The Sprayer should now be ready for use ***

Assembly Procedure (LG-2500-303)