Page 2

IMPORTANT:

Remove tank lid and be sure the tank is clean and

free of any foreign material. Rinse tank out of any tank residue

before filling with water to test.

Testing the Sprayer

NOTE:

It is VERY important for you to test your sprayer with plain water before

actual spraying is attempted. This will enable you to check the sprayer

for leaks without the possibility of losing any expensive chemicals.

Fill the tank about 1/2 full with plain water and drive to the starting place for

spraying.

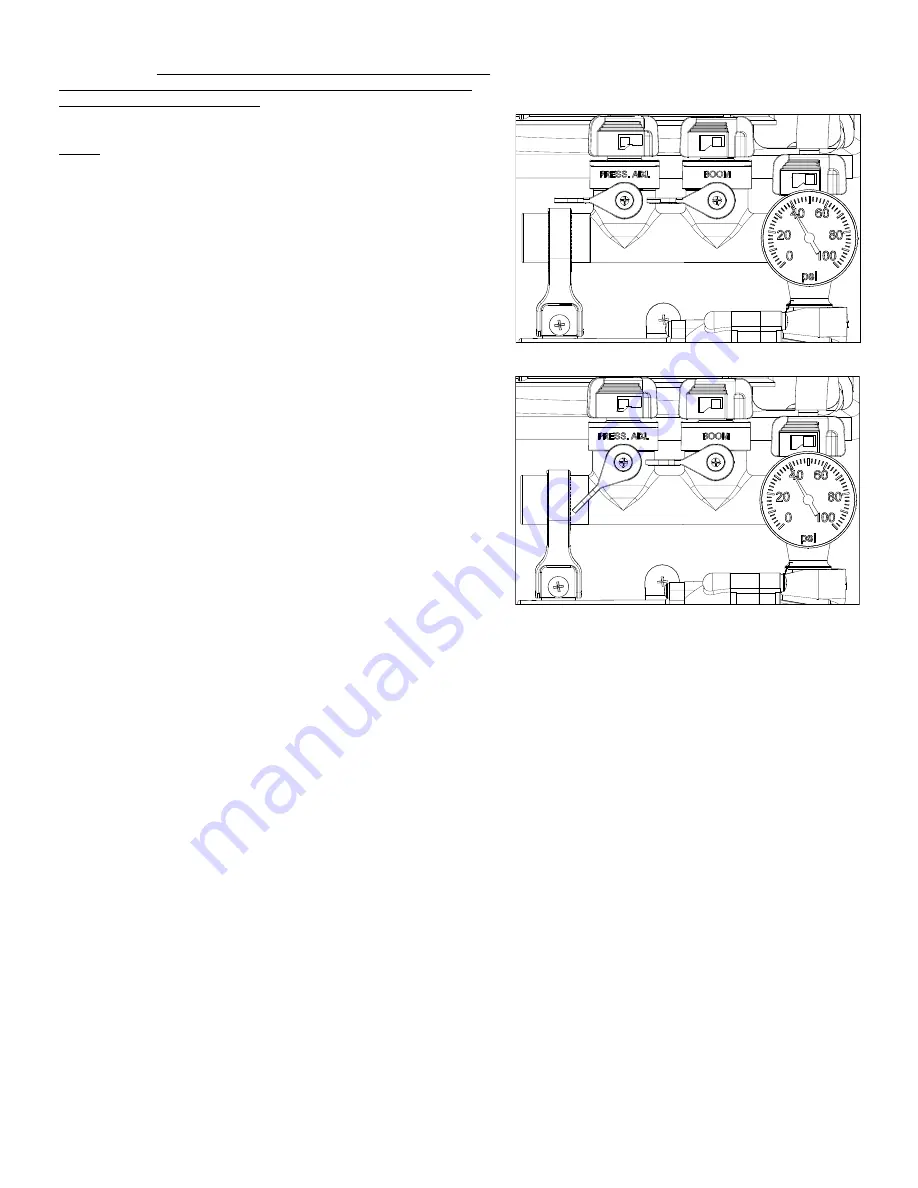

When you are ready to spray, close both valves on manifold (Detail A). This will

start solution spraying from the spraygun when trigger is pulled. The pressure will

decrease slightly when spraying.

Adjust the pressure by turning the “ON/OFF” valve lever on the bypass line valve

(Detail B). Make sure your pattern is sufficient. You may down-pressure the sys-

tem by ‘bypassing’ solution back into the tank. This is achieved by opening the

bypass valve. Regulating pressure is done in this manner.

Read the operating instructions and initially begin spraying by closing both

valves (Detail A). This will enable the air in the line to be eliminated (purged)

through the tip, while building pressure. When everything tests all right (no leaks

and good pressure), add the desired chemicals to the mixture and water combi-

nation and start your spraying operation. Adjust the pressure and spray as you

did in the testing procedure.

Conditions of weather and terrain must be considered when setting the sprayer.

Do not spray on windy days. Protective clothing must be worn in some cases.

Be sure to read the chemical label(s) before application!

Operation

The pumping system draws solution from the tank, through the strainer and to

the pump. The pump forces the solution under pressure to the handgun.

Manifold Valves CLOSED

Detail A

Detail B

Connect the lead wire to a fully charged 12 volt battery. You may use either a stand-alone battery or the battery on your towing vehicle. Connect to the

positive (red) terminal first, then connect to the negative (black) terminal. Then connect the end of the lead wire to the end of the pump. When discon-

necting, disconnect the end of the pump wire from the lead wire, then disconnect the negative (black) connection and finally the positive (red) connec-

tion. The lead wire has an On/Off switch to activate the pump. “-” is on and “O” is off.

Fill the tank part way with water and then add the desired amount of chemical to be sprayed. Finish filling tank to proper level. Turn the pump on and

by depressing the “-” side of the rocker switch. The pump is equipped with a pressure switch that is pre-set at the factory to shut the pump off when all

discharges are closed.

The pump will turn back on when one of the following actions occurs:

Handgun lever is squeezed to spray the handgun.

Bypass valve is opened to re-circulate solution back into the tank.

When spraying with the handgun, pressure may be reduced by slowly opening the bypass valve until desired pressure is achieved. Opening the valve

decreases pressure, closing the valve increases pressure.

Maintenance During/After Spraying

Periodically check the strainer and clean the screen on your intake line.

Proper care and maintenance will prolong the life of your sprayer.

After use, drain the tank and store or dispose of chemical properly. Fill the sprayer half way with clean water. Start the pump and allow the water to

pump through the entire plumbing system and nozzle. Drain and then refill half full, add the recommended amount of a good quality tank cleaner, such

as FIMCO Tank Neutralizer and Cleaner. (If no tank cleaner is available, you may substitute dish soap for this step, about 1-2 oz. per gallon). Turn

pump on and circulate through system for 15 minutes and then spray out through handgun nozzle. Refill sprayer half way with clean water and repeat.

Follow the chemical manufacturer’s disposal instructions of all wash or rinsing water.

If handgun nozzle needs cleaning, remove from the sprayer and soak in warm soapy water. Clean with a soft bristled brush or toothpick if necessary.

Never use a metal object. Even the slightest damage can change the flow rate and spray distribution. Water rinse and dry the tip before storing.

WARNING:

Some chemicals will damage the pump valves if allowed to soak untreated for a length of time! ALWAYS flush the pump as

instructed after each use. DO NOT allow chemicals to sit in the pump for extended times of idleness. Follow the chemical manufacturer’s

instructions on disposal of all waste water from the sprayer.