Page 2

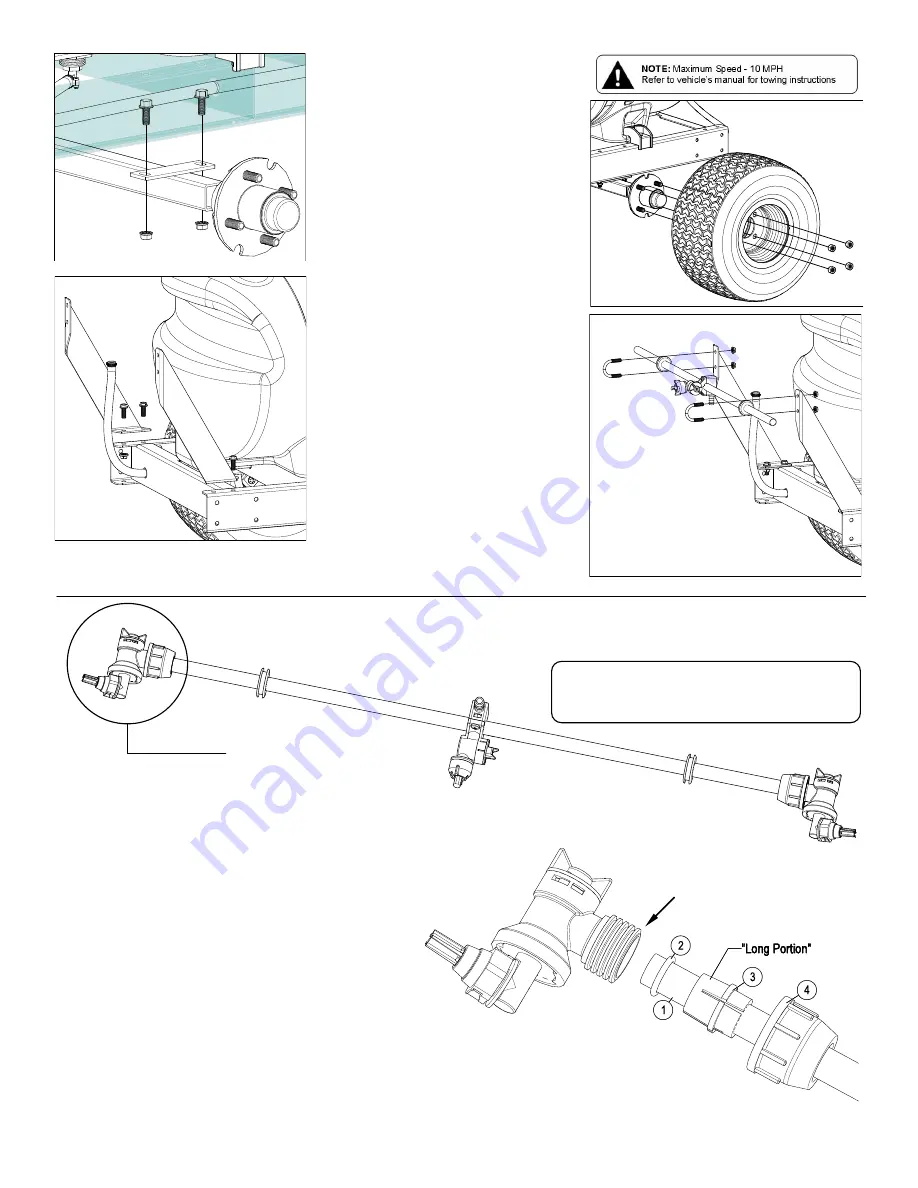

Step 1:

Attach the axle to the trailer frame with (4) bolts

& nuts as shown.

Step 2:

Slide a wheel onto the hub of the axle and use

the wheel nuts to hold the wheel in place. Re-

peat for other side.

Step 3:

The left and right boom mounting brackets are

to be mounted on the trailer frame. Use 4 bolts

and nuts to secure them in place.

Step 4:

Center the boom tube on the boom mounts

and secure in place with the (2) round U-bolts

and whiz nuts provided.

Make sure the U-bolts are positioned within the

grooves of the grommets on the boom tube.

NOTE:

The purpose of these grommets is to

prevent metal-to-metal contact between the U-

bolts, boom tube and boom mounting brackets.

The grommets will ‘compress’ as you tighten

the whiz locknuts onto the U-bolts. Tighten just

so that the boom tube will NOT rotate within

the grommets. Alternate the tightening of the

locknuts to provide even pressure on the grom-

met.

**DO NOT OVER TIGHTEN the whiz lock-

nuts, as this may cause the boom tube to

flatten slightly!

See Below for end nozzle attachment.

End Nozzle Assembly Procedure

For Boomless “Wet” Boom

Your boom will come with the (2) end nozzle assemblies

NOT affixed to your boom tube. Follow the instructions

below to attach these properly to the boom tube, as

shown.

Assembled

End Nozzle

1. Start by sliding Item 4, 3, 2 onto the boom tube

(Item 1) as shown, leaving about 1/2” to 3/4”

between the end of the boom tube and Item 2.

Make sure the “Long” portion of Item 3 is facing the

nozzle end.

2. Slide the (complete) end nozzle assembly onto the

stainless steel boom tube, with a somewhat

“twisting” motion, so that the end face of the boom

tube “butts” up against the surface face inside the

nozzle body.

3. Now push the “compression olive” (Item 3) against

O-ring (Item 2) and slide (both) into the nozzle

body opening firmly.

4. Firmly tighten flynut (Item 4) onto threads of

nozzle body.

5. Repeat for other side.

NOTE: If water is shooting back on the boom tube,

item 2 is not in the correct placement.

Item 2 is shipped inside of

the end nozzle assembly.

Remove & place on tube.

Step 5:

Step 1:

Step 3:

Step 2:

Step 4:

Summary of Contents for 5301307

Page 11: ...Page 11 NOTES ...