Page 6

1. Use a pressure relief device on the discharge side of the

pump to prevent damage from pressure buildup when the

pump discharge is blocked or otherwise closed and the pow-

er source is still running.

2.

WARNING:

Never pump flammable or explosive fluids such

as gasoline, fuel oil, kerosene, etc. Never use in explosive

atmospheres. The pump should be used only with liquids

compatible with the pump component materials. Failure to

follow this warning can result in personal injury and/or prop-

erty damage and will void the product warranty.

3. Never pump acids (i.e. acid fertilizer) with Super Rollers!

4. Never run the pump faster than maximum recommended

speed.

5. Never pump at pressures higher than the maximum recom-

mended pressure.

6. Never pump liquids at temperatures higher than the recom-

mended maximum temperatures (140°F/60°C).

7. Make certain that the power source conforms to the require-

ments of your equipment.

8. Provide adequate protection in guarding around the moving

parts such as the shaft and pulleys.

Roller Pump General Safety Information

9. Disconnect power before servicing.

10. Release all pressure within the system before servicing any

component.

11. Drain all liquids from the system before servicing any com-

ponent.

12. Check all hoses for weak or worn condition before each use.

Make certain that all connections are tight and secure.

13. Periodically inspect the pump and the system components.

Perform routine maintenance as required.

14. Never operate a gasoline engine in an enclosed area. Be

sure the area is well ventilated.

15. Use only pipe, hose and fittings rated for the maximum psi

rating of the pump.

16. Never use pump for pumping water or other liquids for hu-

man or animal consumption.

WARNING: Never pump corrosive or abrasive liquids as these

will cause rapid wear or deterioration of the body, rotor, shaft and

seals in the pump. The pump should be used on with liquids

compatible with pump component materials. Never exceed maxi-

mum specified rpm and pressure. Never run pump dry. Failure to

follow this warning will void the product warranty.

Priming the Pump:

To help prime the pump, keep the inlet or suction line as short as

possible with a minimum of bends, elbows and kinks. Make sure

all connections are tight and do not leak air. Make sure line

strainer is free of debris. If pump does not self-prime, disconnect

suction hose, fill with water and reconnect to liquid source. Often

a squirt of oil into the ports of the pump will seal clearance and

help priming.

Care of the Pump:

Proper care and maintenance will keep your pump wear at a

minimum and will keep it running smoothly and trouble-free for a

long time.

Roller Pump Operation & Maintenance

Flush the Pump After Each Use

One of the common causes of faulty pump performance is

“gumming” or corrosion inside the pump. This prevents

rollers from moving freely in their rotor slots. Flush the

pump with a solution that will neutralize liquid pumped,

mixed according to manufacturer’s directions.

To Prevent Corrosion:

After cleaning pump as above, flush it with a 50-50 solution of

permanent-type automotive antifreeze (containing a rust inhibitor)

and water. A rust inhibitor can also be squirted into the ports of

the pump. Turn shaft several times to draw protective liquid

through pump and coat entire inner surface. Drain pump and

plug ports to keep out air during storage. For short periods of

idleness, noncorrosive liquids may be left in the pump, but air

must be kept out. Plug ports or seal port connections.

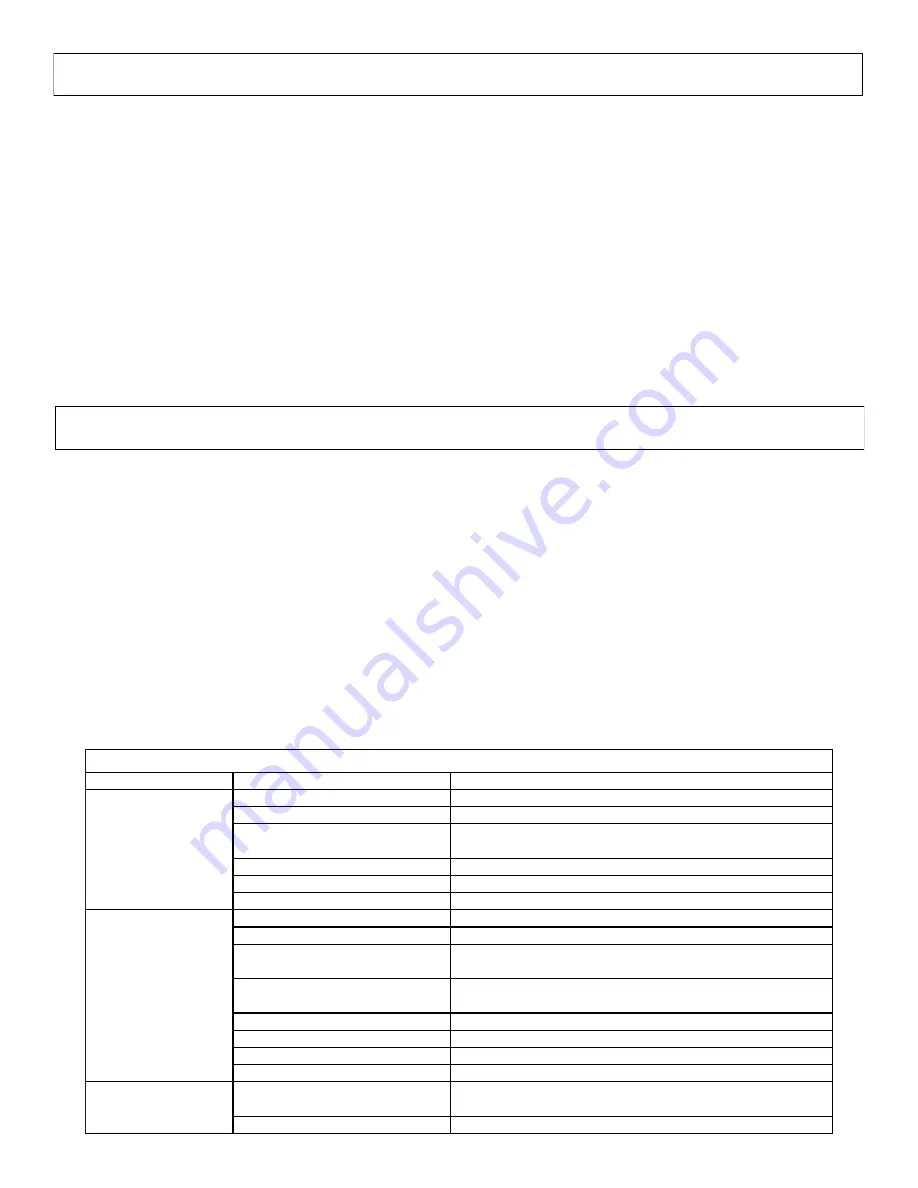

Symptom

Probable Cause(s)

Corrective Action

Leak in suction line

Check hose and fittings for leaks and correct

Obstruction in suction line

Inspect hose for debris or loose inner liner in hose

Suction hose sucked to

bottom or side of tank

Cut a notch or "V" in end of suction hose

Rollers stuck in pump

Disassemble pump and inspect rollers

Pump seals leaking air

Replace seals

Clogged suction strainer

Check strainer and clean it regularly

Kinked or blocked suction hose

Inspect suction hose and repair as necessary

Air leak in inlet side plumbing

Check hose and connections for leaks

Use pipe joint sealant and retighten connections

Relief valve setting too low

or weakened spring

Check relief valve and correct setting

Faulty Gauge

Replace gauge

Pump seals leak air

Replace seals

Nozzle orifices worn

Replace nozzles

Pump worn

Repair pump

Corrosion (rust), scale or residue

Loosen endplate bolts. Squirt oil into ports to help free rotor.

Retighten bolts.

Solid object lodged in pump.

Disassemble pump and remove objects

Troubleshooting

Pump Does Not Prime

Loss of Pressure

Pump will not turn

Summary of Contents for 5301307

Page 11: ...Page 11 NOTES ...