Page 10

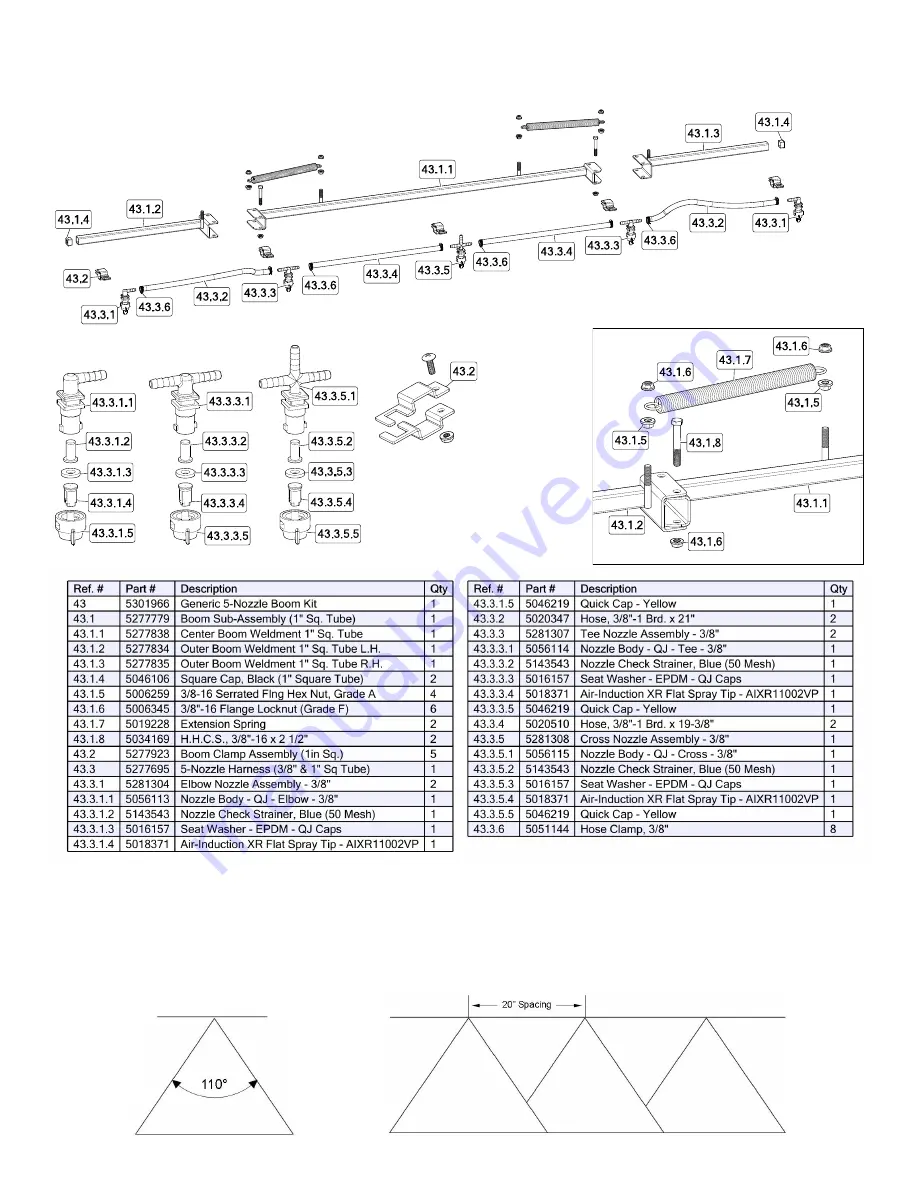

5-Nozzle Boom Assembly

(with 3/8” Hose, 1” Sq. Tubing & AIXR11002VP Tips)

Opposite side has typical hardware setup

See Hinge Detail

Hinge Detail

Elbow TEE CROSS

Clamp

Bag of 5:

5277729

110° wide, tapered flat spray angle with air induction

technology for better drift management

Made of 2-piece UHMWPE polymer construction which

provides excellent chemical resistance, including acids,

as well as exceptional wear life

Compact size to prevent tip damage

Removable pre-orifice

Excellent for systemic products and drift management

Based on the minimum overlap required to obtain uniform

distribution with 110° tips and 20” spacing.

Suggested Minimum Spray Height: 16”-18” above what is

being sprayed (to plant, not ground).

Optimum Spray Height: 20”