Page 7

28”

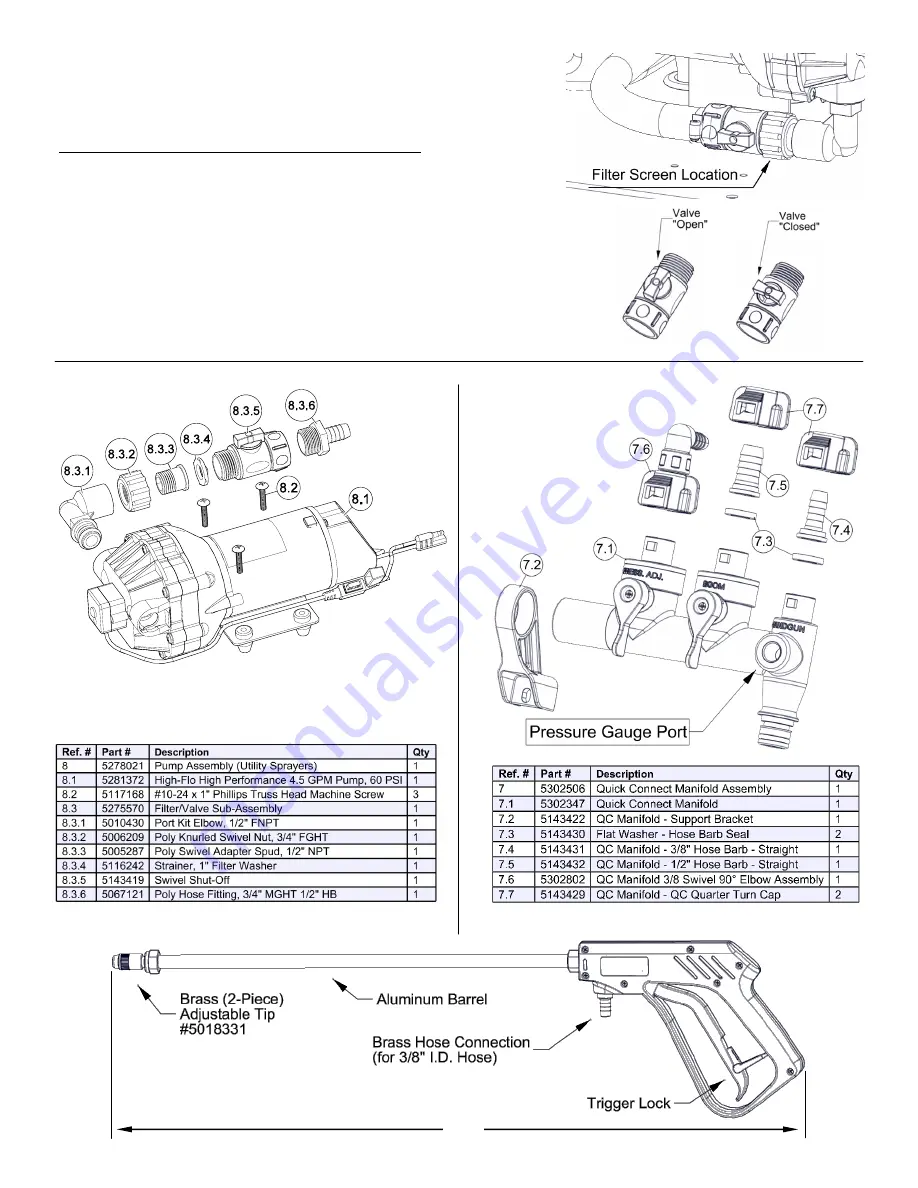

(Pistol-Grip) Handgun #5273959

Pump Assembly

#5278021

Manifold

Assembly

#5302506

There is a shut-off valve on the intake line, next to the pump. It is at this

location so you can shut off the flow of solution to access your system’s screen for

cleaning.

Checking/Cleaning the sprayer’s filter/screen:

Start your pump and before it shuts off, reach down and shut the valve to the

‘Closed’ position (lever is perpendicular to the flow of fluid), then shut off your

pump.

Unscrew the knurled nut from the shut-off valve, leaving the valve connected to

the tank.

Swing (swivel) the intake assembly towards you. Look in the nut you JUST

unscrewed. There is a screen/washer there.

Remove the screen and clean as necessary. Replace when done and reassemble

the entire assembly.

Make sure the valve is turned to the ‘Open’ position before restarting your pump.