Page 6

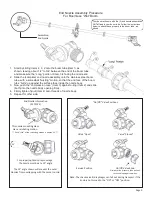

Troubleshoo ng the Pump

:

Motor does not run:

x

Check for loose wiring connec on(s).

x

Make sure the 'ON/OFF' switch in the lead wire assembly is in the

'ON' posi on. “I" is the 'ON' posi on and 'O' is the 'OFF' posi on.

x

Check for defec ve pressure switch. Make sure you are connected to

a good 12 volt power source. Make sure any on/o

ff

switches are in

the 'on' posi on.

x

Remove the cap to the pressure switch. Pull both red wires o

ff

of

their terminals, and touch the two ends together. If your pump runs

when you do this, your pressure switch will need to be replaced.

x

Check the fuse.

x

Check for low voltage at the power supply.

Pump does not prime:

x

Check for air leaks in supply line.

x

Check for debris in the check valve assembly.

x

Check for defec ve check valve.

x

Check for clogged strainer/

fi

lter.

x

Check for cracks in the pump housing.

x

Check for empty product supply.

DO

x

Clean and rinse your pump after each use with Fimco Tank

Neutralizer

x

Winterize your pump or sprayer by rinsing, draining and

running RV Antifreeze through it before storing for the winter.

x

Use clean water for your spray mixture

x

Store inside a building when not in use.

DON’T

x

Use to pump bleach.

x

Use to pump petroleum products such as diesel fuel,

gasoline or kerosene

x

Leave your pump sit with spray mixture in it for extended

periods

x

Use dirty or unfiltered water for spraying

Pulsa ng

fl

ow (surging):

x

Check for defec ve pressure switch.

x

Check for leaks in the discharge line.

x

Check for restric on in the discharge line.

x

Check for debris in nozzle ori

fi

ce.

x

Discharge hose may be too long.

x

Check for clogged strainer.

Motor con nues to run a er discharge is shut o

ff

:

x

Check for empty product supply.

x

Check for open bypass valve. (if equipped)

x

Check for low voltage.

x

Check for leak in discharge line.

x

Check for defec ve or dirty check valve.

x

Check for defec ve pressure switch.

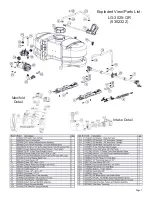

Pump Model: 5277982

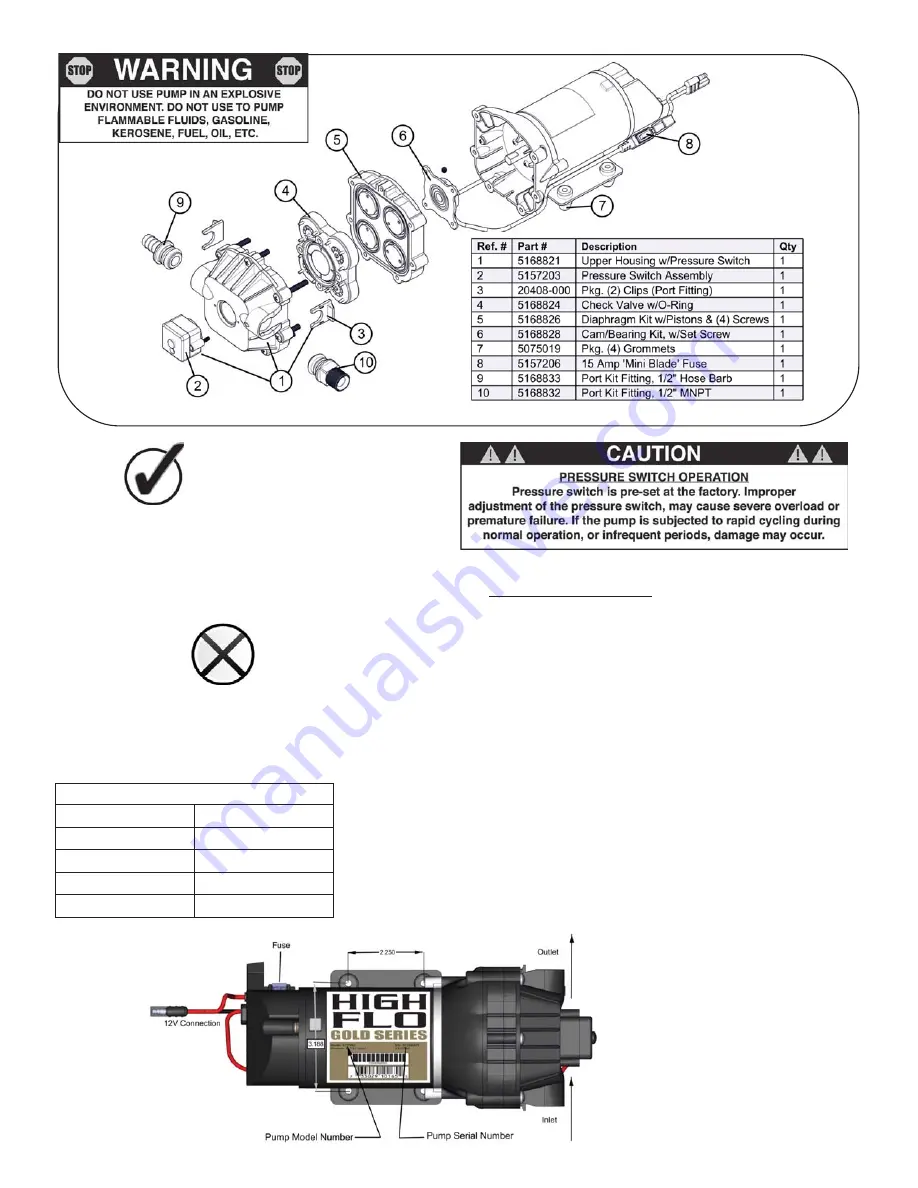

Available Replacement Parts

Pump Specifications

Current:

7.4 Amps @ 40 PSI

Check Valve:

Viton

Wetted Parts Housing: Polypropylene

Diaphragm: Santoprene

Liquid Temperature:

130° F max.

GPM=Gallons Per Minute

PSI=Pounds per Square Inch

DC=Direct Current