Page 7

Try another 12-Volt battery

Quarter turn at a time clockwise until surging stops

Defective pressure switch

Troubleshooting

Bypass is not completely closed

System has leaks

Check for worn or dirty check valve

Excessive voltage

Improper adjustment of pressure switch

Damaged or defective wiring harness

Check for proper voltage

Check for worn or dirty check valve

Low flow may cause pump to surge

Spray wand is adjusted for a small or fine spray pattern

Slightly open bypass (if applicable) to overcome

If needed, pressure switch may need to be adjusted

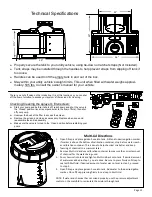

Pump will not run:

Low Pressure/Low Flow:

Pump surges:

Pump continues to run:

Fuse blows:

Check for loose wiring

Make sure the ON/OFF switch is on

Check the fuse

Check for defective pressure switch

Check for a clogged strainer

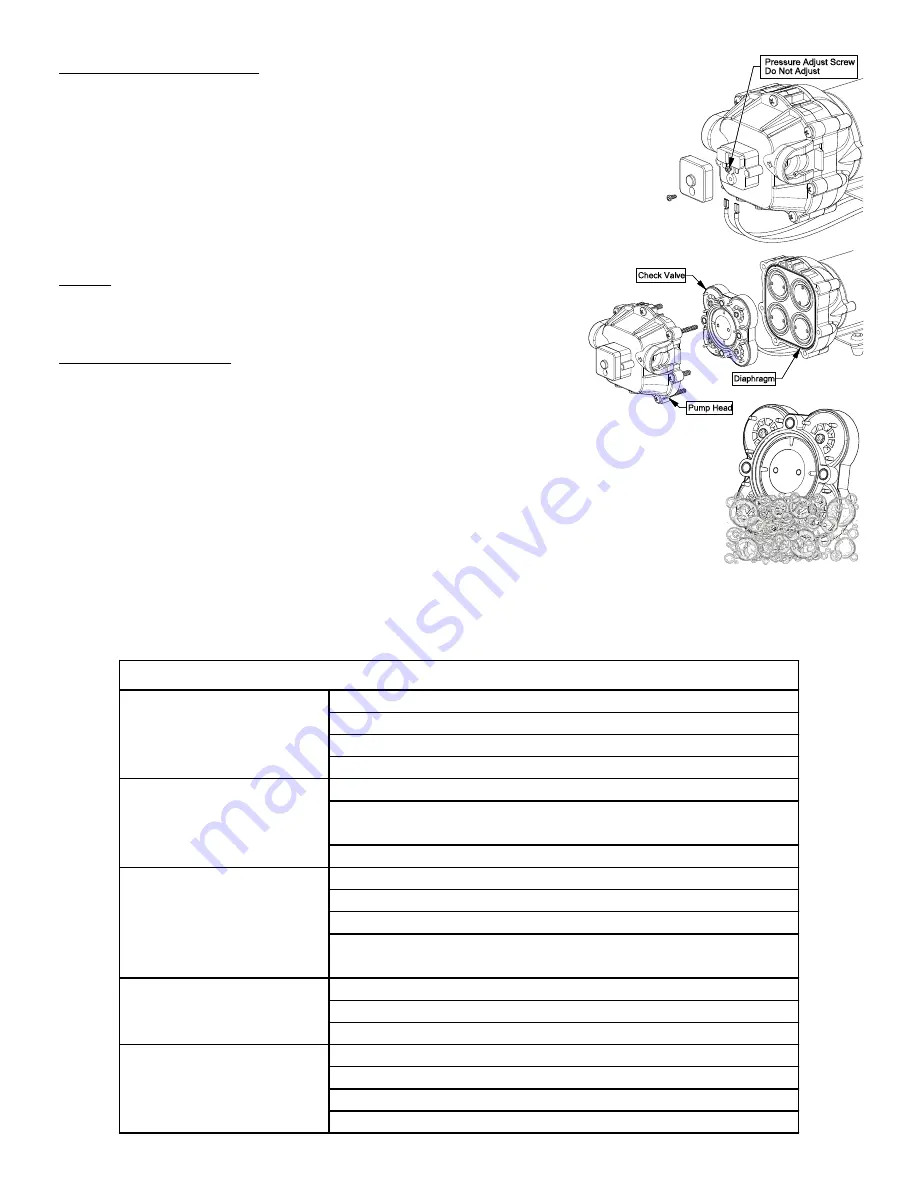

Cleaning the Check Valve

:

If you’re experiencing little to no pressure or the pump is not priming and you’ve checked your filter

screen and it’s clean, and you’ve gone through the other trouble shooting tips, you may need to

clean the check valve.

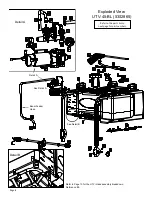

Remove the head of the pump, which is held on by 7 screws.

The first piece inside the head of the pump is called a check valve, it’s the part responsible for building up pressure

and pumping water/solution through the lines.

Clean the check valve under hot, soapy water (such as a good grade dish soap).

Give it a very light scrubbing with something like an old toothbrush, something with soft bristles.

Then let it soak for about an hour or so in the hot soapy solution and replace in the pump and reassemble the pump.

Most times this will restore most, if not all of the prime of a pump.

If you’re still having issues with pressure after this step, it would be recommended to replace this part.

Checking the Pressure Switch

:

If your motor is not running and you’ve checked the following: for loose wiring connections, fuse, the switch on

the lead wire was “ON” and made sure you were connected to a fully charged battery and everything is fine, but

the motor won’t run, then it’s time to check to see if the pressure switch is bad.

Remove the cover off the 1” square box (pressure switch) on the head of the pump, the cover is held on by

one phillips-head screw. This will expose the two red wires.

With the pump connected to a good 12 volt power source and everything on.

Slip the two red wires off the terminals and touch them together.

If the motor runs, it means the pressure switch is bad and needs to be replaced.

If it still doesn’t run, try bypassing the switch in the lead wire or using another lead wire. Even if a tester shows

power to the pressure switch, it still could be the switch in the wire that is causing the problem. If still not

responsive, use a voltmeter or electrical tester to make sure you are getting power to the head of the pump, as

it could possibly be something in one of the wires or even the lead wire assembly may need to be replaced.

Warning:

It is NOT recommended to run the pump this way, as the pump will continue to run and

not shut off.

This could result in blown hoses when all discharges are closed.

Also, this could result in premature failure of the pump completely.