Page 8

DO

Clean and rinse your pump after each use with Fimco Tank

Neutralizer

Winterize your pump or sprayer by rinsing, draining and

running RV Antifreeze through it before storing for the winter.

Use clean water for your spray mixture

Store inside a building when not in use.

DON’T

Use to pump bleach.

Use to pump petroleum products such as diesel fuel,

gasoline or kerosene

Leave your pump sit with spray mixture in it for extended

periods

Use dirty or unfiltered water for spraying

Troubleshooting the Pump:

Motor does not run:

Check for loose wiring connection(s).

Make sure the 'ON/OFF' switch in the lead wire assembly is

in the 'ON' position. "I" is the 'ON' position and 'O' is the 'OFF'

position.

Check for defective pressure switch. Make sure you are con-

nected to a good 12 volt power source. Make sure any on/

off switches are in the 'on' position. Remove the cap to the

pressure switch. Pull both red wires off of their terminals, and

touch the two ends together. If your pump runs when you do

this, your pressure switch will need to be replaced.

Check the fuse.

Check for low voltage at the power supply.

Pump does not prime:

Check for air leaks in supply line.

Check for debris in the check valve assembly.

Check for defective check valve.

Check for clogged strainer/filter.

Check for cracks in the pump housing.

Check for empty product supply.

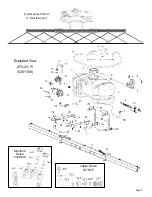

Pump Model: 5277982

Pump Specifications

Current:

7.4 Amps @ 40 PSI

Check Valve:

Viton

Wetted Parts Housing: Polypropylene

Diaphragm:

Santoprene

Liquid Temperature:

130° F max.

GPM=Gallons Per Minute

PSI=Pounds per Square Inch

DC=Direct Current

Pulsating flow (surging):

Check for defective pressure switch.

Check for leaks in the discharge line.

Check for restriction in the discharge line.

Check for debris in nozzle orifice.

Discharge hose may be too long.

Check for clogged strainer.

Motor continues to run after discharge is shut off:

Check for empty product supply.

Check for open bypass valve. (if equipped)

Check for low voltage.

Check for leak in discharge line.

Check for defective or dirty check valve.